A treatment method for low-temperature flue gas

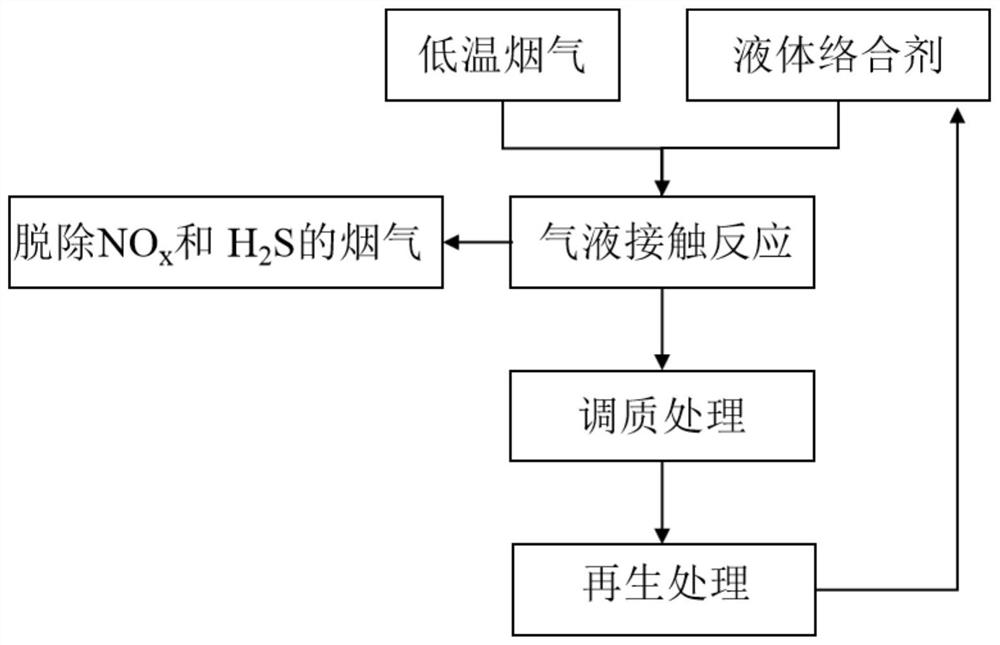

A technology of low-temperature flue gas and treatment method, which is applied in the directions of gas treatment, separation method, chemical instrument and method, etc., can solve the problem of incapable of simultaneous desulfurization and denitration treatment of low-temperature flue gas.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

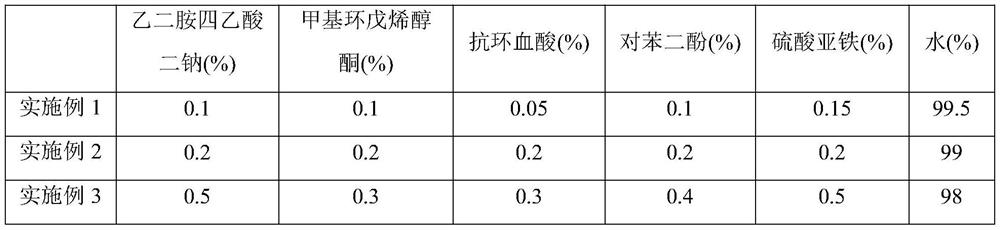

Embodiment 1

[0051](1) Conduct gas-liquid contact reaction between low-temperature flue gas (temperature 35°C) and liquid complexing agent, control the volume ratio of liquid complexing agent and low-temperature flue gas to 1:1, the reaction temperature is 35°C, and the reaction time is 10s, to obtain the exhausted liquid complexing agent and the flue gas from which nitrogen oxides and hydrogen sulfide have been removed;

[0052] (2) Carry out tempering treatment with the invalidated liquid complexing agent obtained in step (1), control the concentration of the obtained tempering liquid complexing agent to be 0.7% by weight, and the pH value is 6.5;

[0053] (3) The tempering liquid complexing agent obtained in step (2) is regenerated under stirring, the reaction temperature is controlled to be 70°C, the reaction time is 60min, and the stirring speed is 500rpm to obtain a regenerated liquid complexing agent, which is recycled for use in In step (1).

Embodiment 2

[0055] (1) Conduct gas-liquid contact reaction between low-temperature flue gas (temperature 45°C) and liquid complexing agent, control the volume ratio of liquid complexing agent and low-temperature flue gas to 3:1, the reaction temperature is 45°C, and the reaction time is 7s, to obtain the exhausted liquid complexing agent and the flue gas from which nitrogen oxides and hydrogen sulfide have been removed;

[0056] (2) Carry out tempering treatment to the invalidated liquid complexing agent obtained in step (1), control the concentration of the obtained tempering liquid complexing agent to be 0.8% by weight, and the pH value is 7;

[0057] (3) The conditioning liquid complexing agent obtained in step (2) is subjected to a regeneration reaction under stirring, the controlled reaction temperature is 80° C., the reaction time is 45 minutes, and the stirring speed is 350 rpm to obtain a regenerated liquid complexing agent, which is recycled for use in In step (1).

Embodiment 3

[0059] (1) Conduct gas-liquid contact reaction between low-temperature flue gas (temperature 50°C) and liquid complexing agent, control the volume ratio of liquid complexing agent and low-temperature flue gas to 5:1, the reaction temperature is 50°C, and the reaction time is 5s, to obtain the exhausted liquid complexing agent and the flue gas from which nitrogen oxides and hydrogen sulfide have been removed;

[0060] (2) Carry out tempering treatment to the invalidated liquid complexing agent obtained in step (1), control the concentration of the obtained tempering liquid complexing agent to be 0.9% by weight, and the pH value is 7.5;

[0061] (3) The conditioning liquid complexing agent obtained in step (2) is subjected to a regeneration reaction under stirring, the reaction temperature is controlled at 90° C., the reaction time is 30 min, and the stirring speed is 150 rpm.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com