An angle-adjustable array microhole laser processing method

A laser processing method and laser technology, applied in metal processing equipment, laser welding equipment, manufacturing tools, etc., can solve complex steps, unfavorable mass production of aperture array micro-holes, difficulty in meeting the requirements of micro-hole processing with large depth-to-diameter ratio, etc. problems, to achieve the effect of improving processing efficiency, improving processing accuracy, and ensuring processing accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

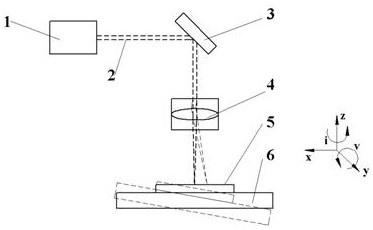

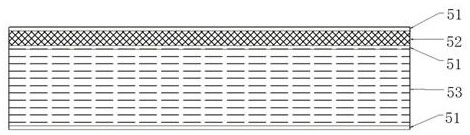

[0032] Such as figure 1 and 2 As shown, a laser 1 emits a laser beam 2, which passes through a mirror 3 to a focusing module 4, and the focused laser beam 2 processes a board 5 placed on an ultra-precision platform 6, and the board 5 is a multilayer PCB. The multi-layer PCB mainly includes a copper clad laminate 51 , a resin layer 52 and an adhesive layer 53 . First, measure the ablation threshold of each layer of the multi-layer PCB5, and determine the output power required for the laser beam 2 microhole processing according to the depth of the laser beam 2 microhole processing, and the output power of the laser beam 2 required for each layer is P1, P2 . Next, operations such as clamping of the workpiece and focusing of the laser beam 2 are carried out. Since this series of steps are familiar to those skilled in the art, details are not repeated here. Set the output power of the laser beam 2 to P1 again, process the copper clad laminate 51 on the top layer, set the process...

Embodiment 2

[0034] Measure the ablation threshold of each layer of the processed plate 5; fix the processed plate 5 on the ultra-precision platform 6; use parameters such as wavelength 355nm, pulse width 50ns, power 20W, repetition frequency 100kHz, defocus amount 0, etc. The laser beam 2 is used for micro-hole processing, and the scanning speed is 700mm / s. During the processing, according to the change of the micro-hole processing depth of the laser beam 2 and the ablation threshold of different materials, the output power of the laser beam 2 can range from 0 to 100W. Adjustments are made to suit different processing requirements.

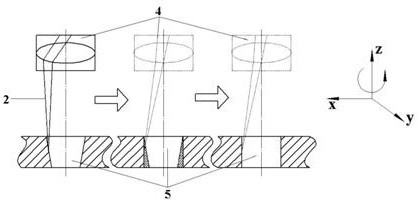

[0035] Such as image 3 As shown, the plate 5 forms a positive taper hole at a certain angle after being processed by the laser beam 2 . At this time, set the output angle of the laser 2 to 2° through the focusing module 4 (adjust the output angle of the laser 2 to -5° to +5° according to actual needs) and adjust the focus position, and output the laser 2 to...

Embodiment 3

[0037] Determination of the ablation threshold of each layer material of the plate 5; fix the plate 5 on the ultra-precision platform 6; use the laser beam 2 with the parameters of wavelength 532nm, pulse width 80ns, power 30W, repetition frequency 100kHz, defocus amount 0, etc. For hole processing, the scanning speed is 800mm / s. During the processing, according to the change of the micro-hole processing depth of the laser beam 2 and the ablation threshold of different materials, the output power of the laser beam 2 can be adjusted within the range of 0-100W to adapt to Different processing requirements.

[0038] Such as Figure 4 As shown, the hole on the plate 5 will form a certain positive cone angle. At this time, the output angle and output power of the laser beam 2 are kept constant, and the rotation angle of the precision platform is adjusted to 30° along the y-axis direction (over The rotation angle of the precision platform 6 is 0-45°), the ultra-precision platform 6...

PUM

| Property | Measurement | Unit |

|---|---|---|

| width | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com