Environment-friendly surface-treated galvanized steel sheet and preparation method thereof

A galvanized steel sheet, surface treatment technology, applied in the direction of hot-dip plating process, coating, metal material coating process, etc., can solve the problems of poor surface quality, low anti-rust ability, bad appearance, etc., to reduce the friction coefficient, Excellent formability and improved formability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1- Embodiment 7

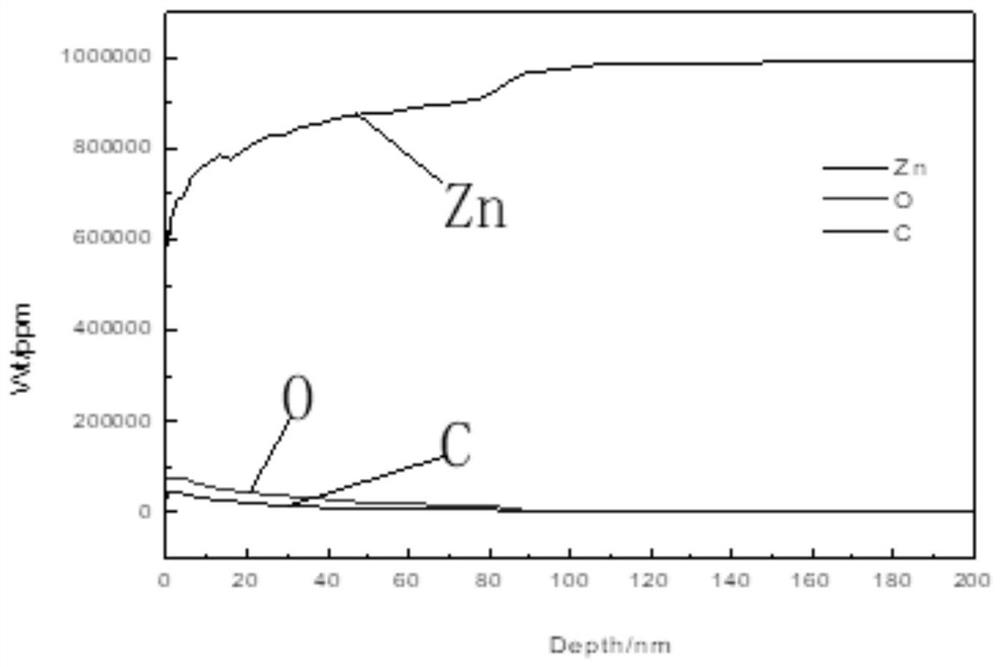

[0044] An environment-friendly surface-treated galvanized steel sheet, which sequentially includes a galvanized layer, a chemical conversion film and an antirust layer.

[0045] The preparation method of the galvanized steel sheet with environment-friendly surface treatment described in embodiment 1-embodiment 7 comprises the following technological process:

[0046] 1) The steel plate is obtained by cold rolling → cleaning → annealing → galvanizing → smoothing to obtain a galvanized steel sheet; the formed galvanized layer includes the following components by mass percentage: Al0.25%, the balance is Zn and unavoidable impurities;

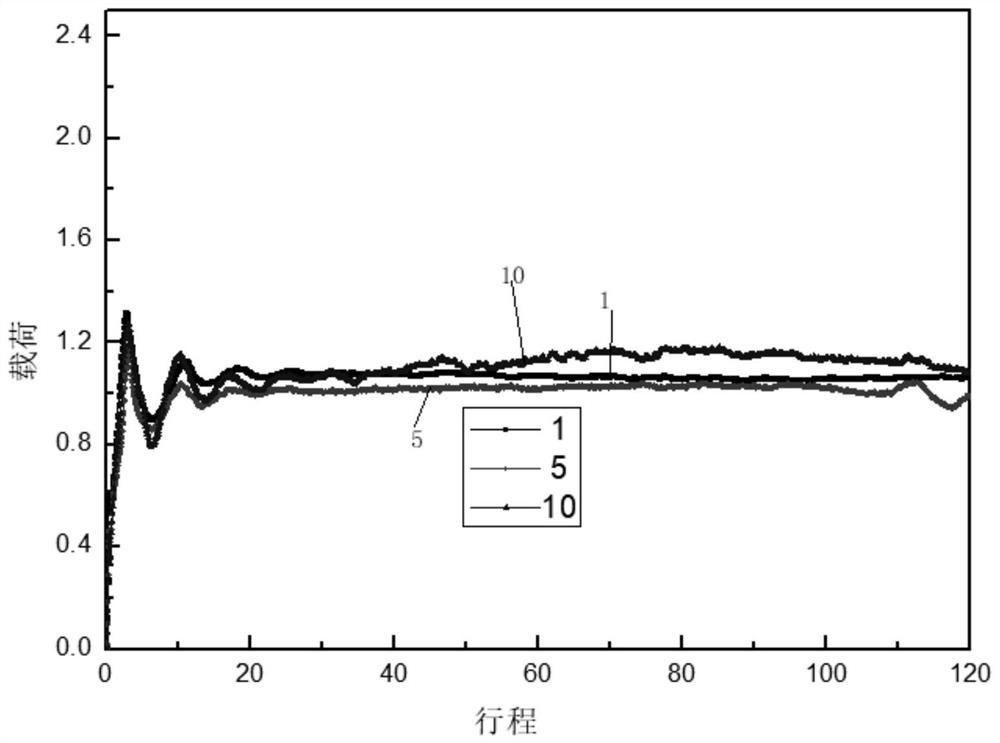

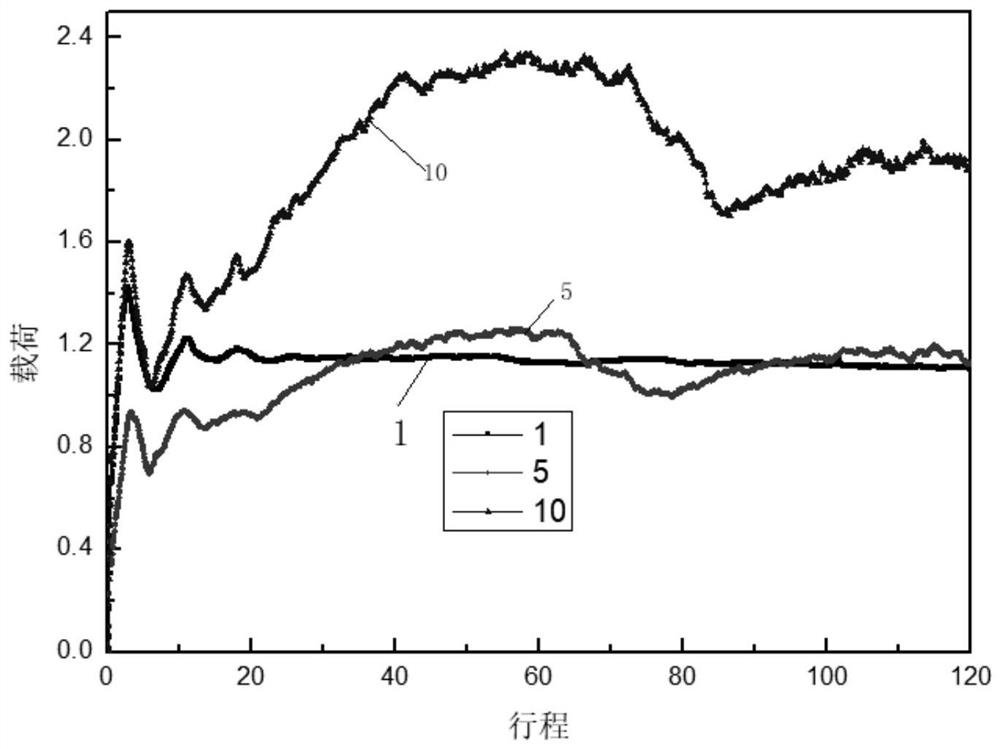

[0047] 2) The method of roller coating is used to uniformly coat the aqueous solution containing one or more of malonic acid, succinic acid, adipic acid, tartaric acid, citric acid or malic acid as a lubricating solution on the surface of the galvanized layer of the galvanized steel sheet, And heat treatment with hot air, heating and baking the ste...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| Adhesion amount | aaaaa | aaaaa |

| surface roughness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com