Belt transferring point semi-closed automatic dust removing device and method

A semi-closed, dust-reducing device technology, applied in cleaning devices, conveyor control devices, transportation and packaging, etc., can solve problems affecting coal mine safety production, high dust concentration, gas accumulation, etc., to isolate the dust transmission path, effectively The effect of dust removal and accumulation prevention

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

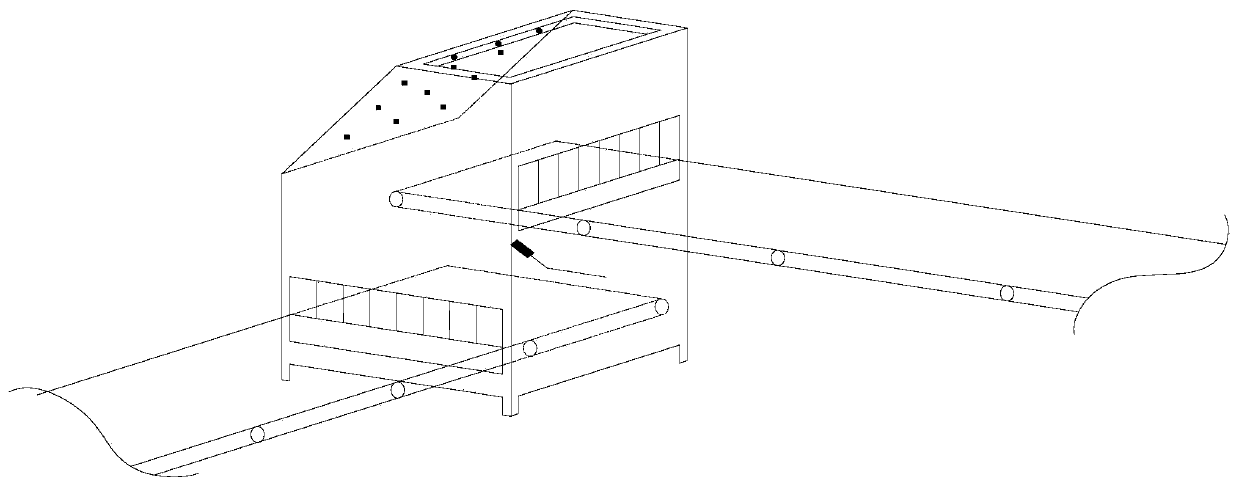

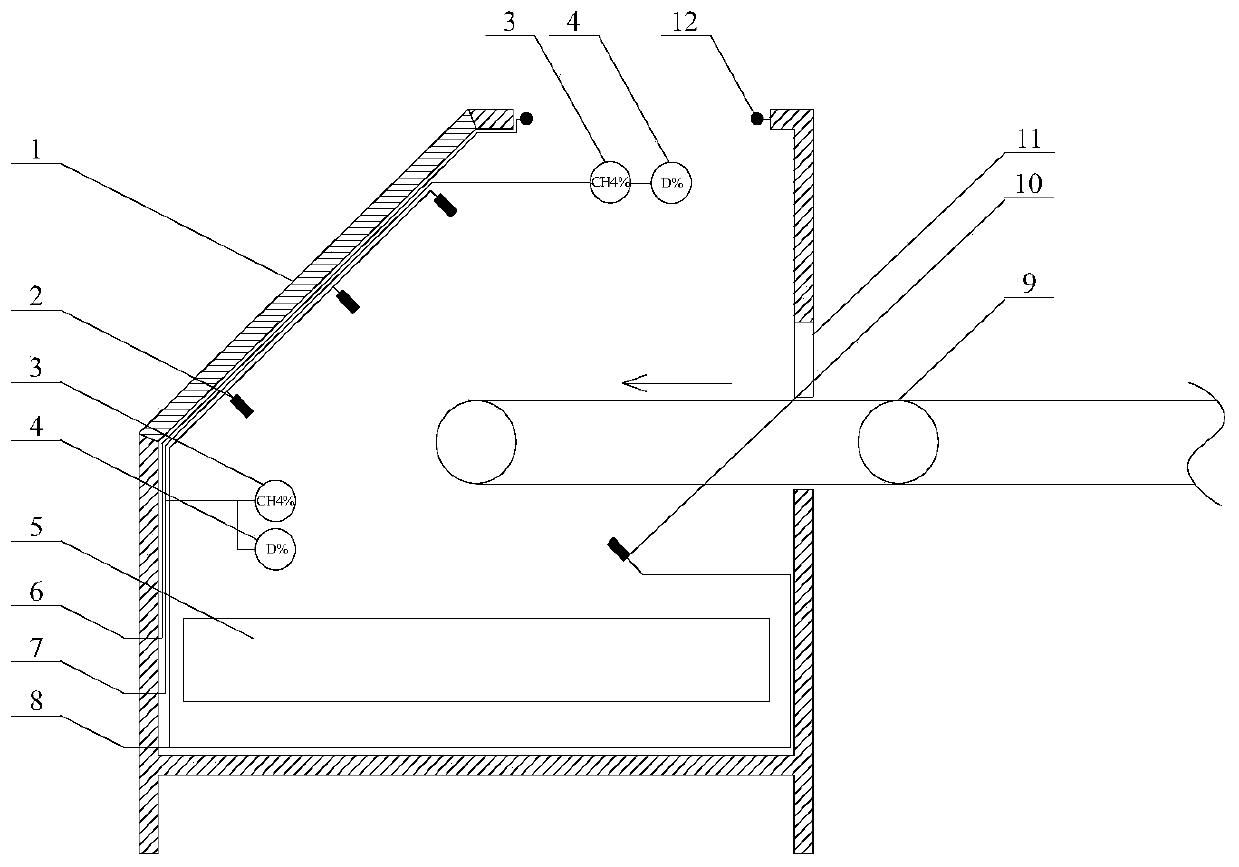

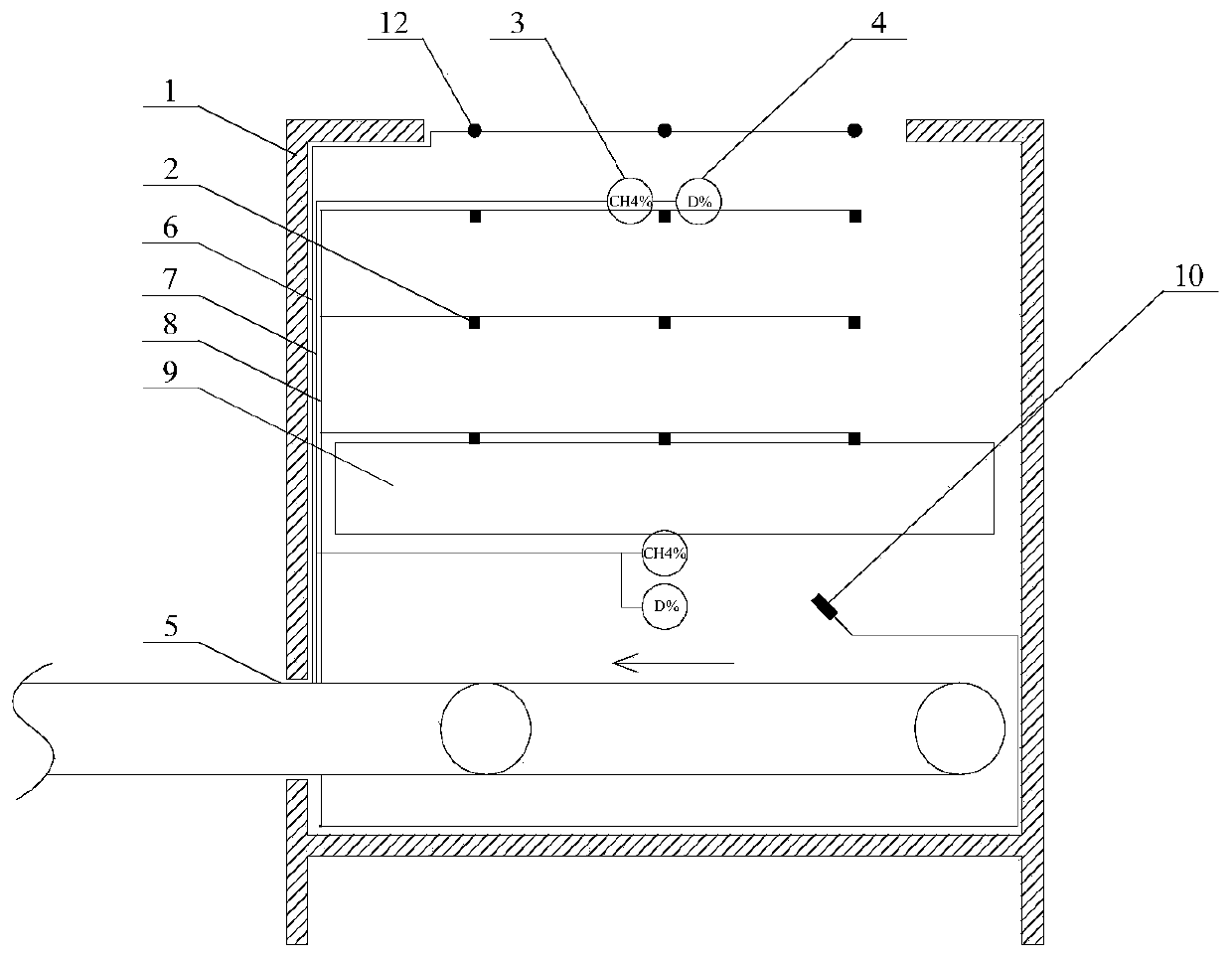

[0034] Such as figure 1 A semi-closed automatic dust reduction device for a belt transfer point is shown, including a semi-closed dust cover 1, and an upper belt for coal to enter the semi-closed dust cover 1 is provided in the middle of the semi-closed dust cover 1 9, the lower part is provided with a lower overlap belt 5 in the semi-closed dust cover 1 for coal transportation, and the upper belt 9 is perpendicular to the lower carrying belt 5, and the coal on the upper belt 9 falls to the The lower part is carried on the belt 5. The upper belt 9 transports coal to the semi-closed dust cover 1 and transports the transported coal to the end of the upper belt 9. When the coal reaches the end of the upper belt 9, it Gravity falls onto the lower carrying belt 5, the coal is transported to the outside of the semi-closed dust cover 1 through the lower carrying belt 5, and the dust in the coal is processed by the semi-closed dust cover 1. The upper belt and the lower part The carryin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com