Prefabricated concrete structure splicing structure

A concrete structure, prefabricated assembly technology, applied in the direction of structural elements, building components, building structures, etc., can solve the problems of increasing construction difficulty and project cost, high construction requirements, and uncompact grouting, and achieves simple and economical production technology. Improve construction efficiency and prevent steel corrosion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The present invention will be further described in detail below in conjunction with the accompanying drawings and specific implementation examples.

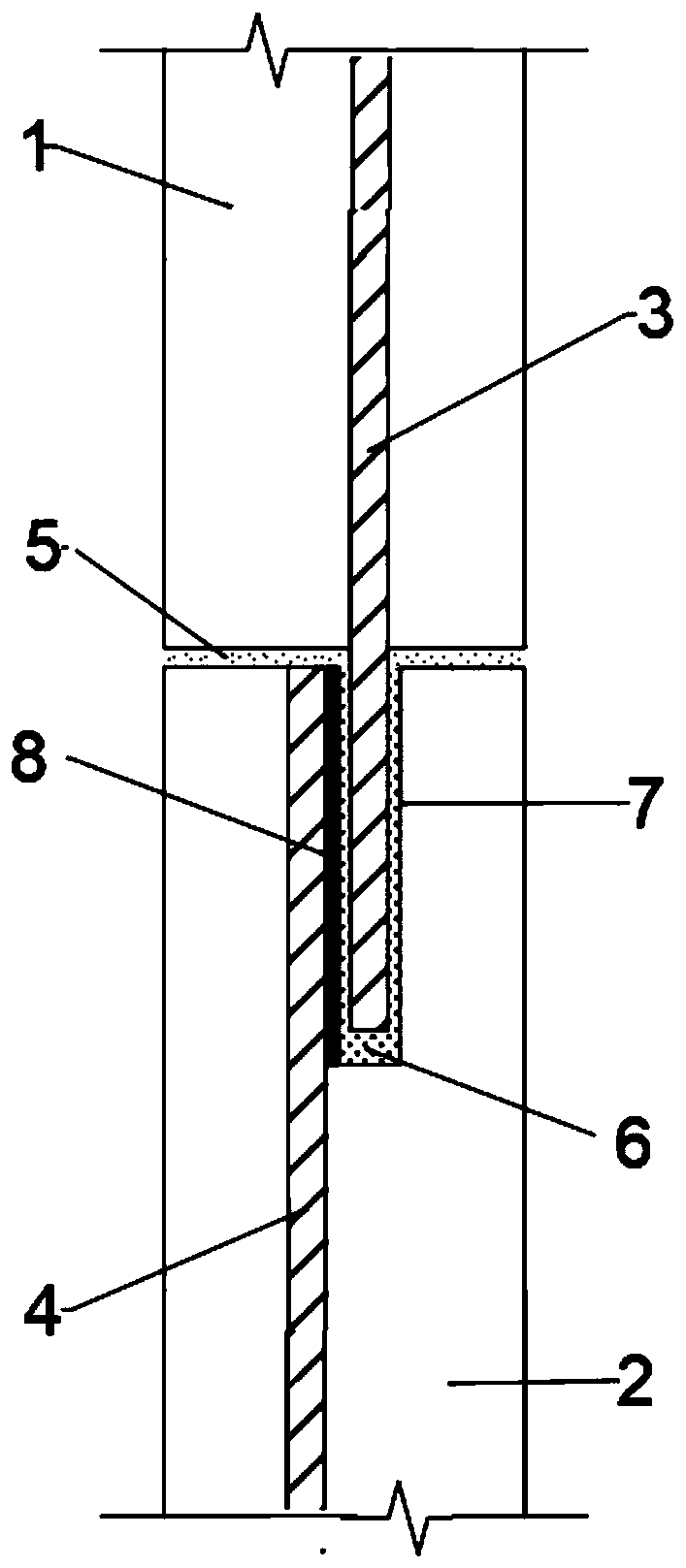

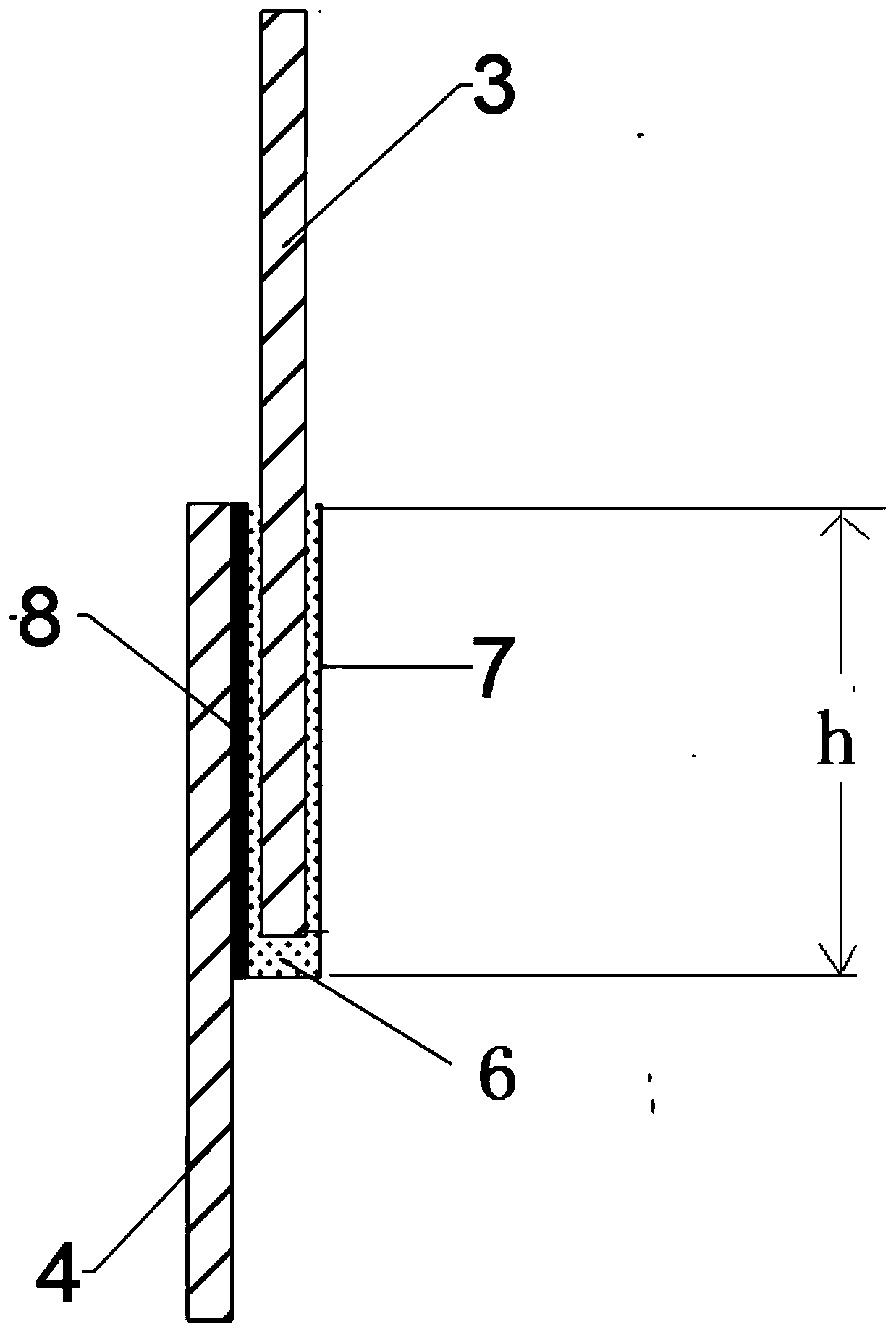

[0019] see figure 1 , a prefabricated assembled concrete structure splicing structure of the present invention includes an upper prefabricated component 1, a lower prefabricated component 2, an upper stressed steel bar 3, a lower stressed steel bar 4, and a steel sleeve 7, which are formed by pre-casting epoxy resin mortar during splicing. The coaxial epoxy resin mortar structure sleeve 6 and the epoxy resin mortar structure splicing layer 5 embedded in the steel sleeve 7. The steel sleeve 7 is an ordinary seamless steel pipe or a straight seam welded pipe.

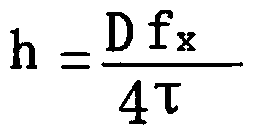

[0020] The steel sleeve 7 and the lower reinforced steel bar 4 are welded together along the axial direction of the steel sleeve 7, and are pre-embedded in the lower prefabricated component 2, and the upper end surface of the steel sleeve 7 is flush with the splicing...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com