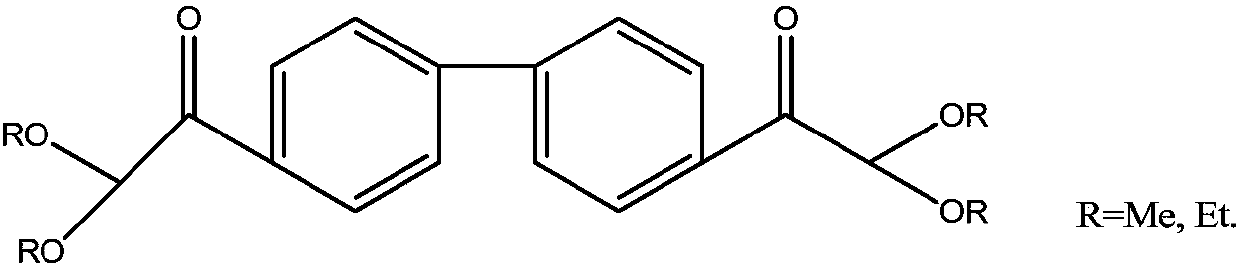

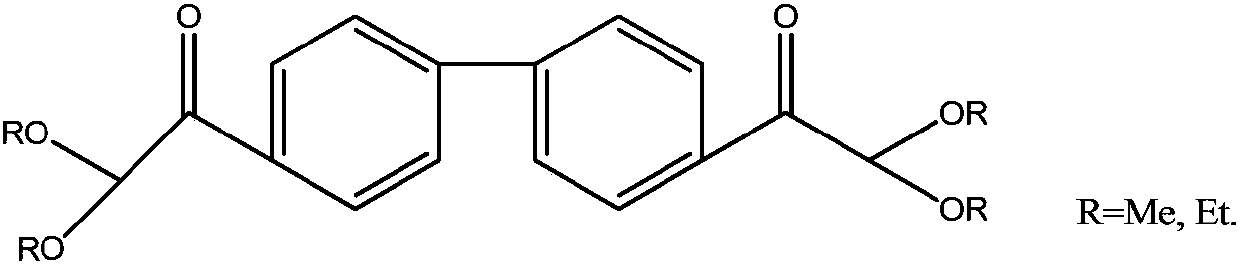

Photoinitiator 4,4'-bis(2,2-dialkoxyacetyl)biphenyl and synthetic method thereof

A dialkoxyacetyl and diethoxyacetyl technology is applied in the application field of photoinitiator 4,4'-dibiphenyl in photopolymerization materials, which can solve problems such as VOC emission and environmental pollution, and achieve optimization Effects of reaction conditions, economical production processes

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

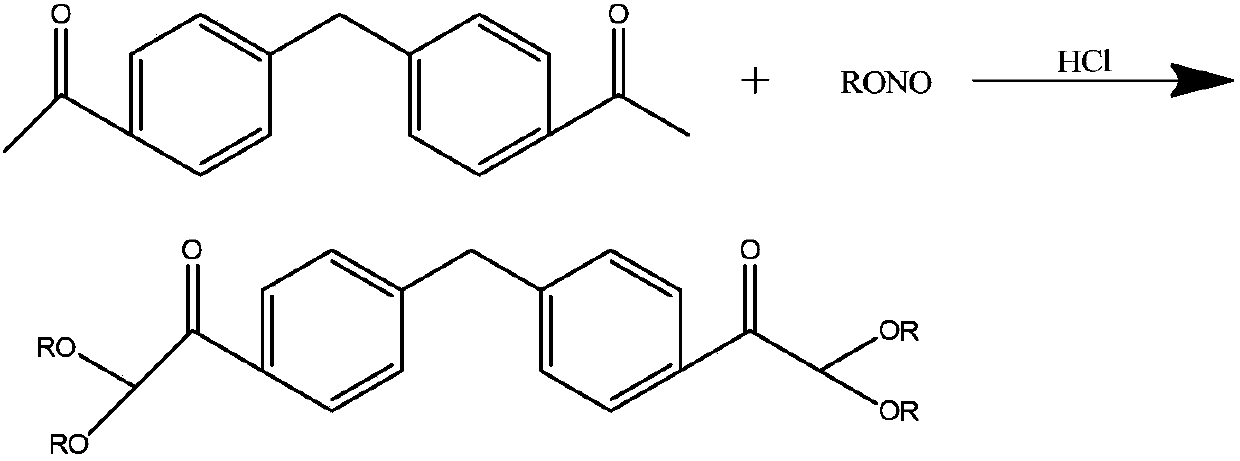

Embodiment 1

[0019] In a 2000-liter reactor, add 600g of ethanol and 238g of 4,4'-diacetylbiphenyl, feed 38g of dry hydrogen chloride gas under ice-water cooling, and feed 268g of methyl nitrite at 30-35°C. Continue to react at this temperature for 4 hours after completion, stop the reaction, distill ethanol off under reduced pressure to obtain a crude product. Distilled under reduced pressure to obtain 297 g of 4,4'-bis(2,2-dialkoxyacetyl)biphenyl with a yield of 83.0%.

Embodiment 2

[0021] In a 2000-liter reactor, add 600g of ethanol and 238g of 4,4'-diacetylbiphenyl, feed 42g of dry hydrogen chloride gas under ice-water cooling, and feed 268g of ethyl nitrite at 30-35°C. Continue to react at this temperature for 4 hours after completion, stop the reaction, distill ethanol off under reduced pressure to obtain a crude product. Distilled under reduced pressure to obtain 298 g of 4,4'-bis(2,2-dialkoxyacetyl)biphenyl with a yield of 83.2%.

Embodiment 3

[0023] In a 2000-liter reactor, add 600g of ethanol and 238g of bis(4-diacetylphenyl)methane, feed 38g of dry hydrogen chloride gas under ice-water cooling, and feed 330g of ethyl nitrite at 30-35°C , continue to react at this temperature for 4 hours after passing through, stop the reaction, and distill ethanol off under reduced pressure to obtain a crude product. Distilled under reduced pressure to obtain 357 g of 4,4'-bis(2,2-dialkoxyacetyl)biphenyl with a yield of 86.2%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com