Optical lens or lens group, process for the production thereof, as well as optical image acquisition device

a technology of optical lenses and lenses, applied in the field of hybrid lenses, can solve the problems of increasing demand, affecting the quality of optical images, and requiring the grinding of precision lenses made of glass at great expense and finished, and achieves the effect of simple and economical production processes and high resolution or imaging quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

embodiment 1

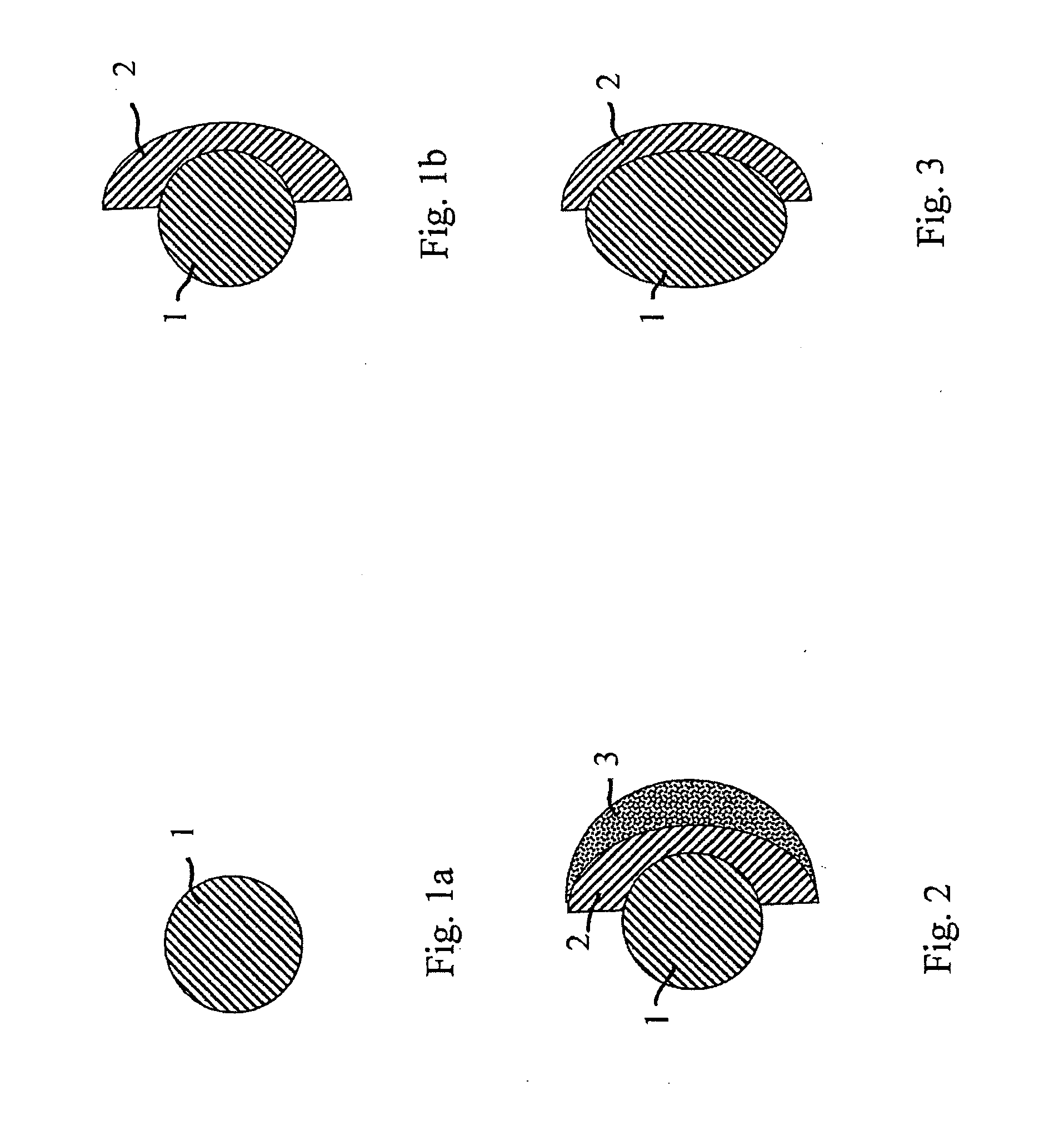

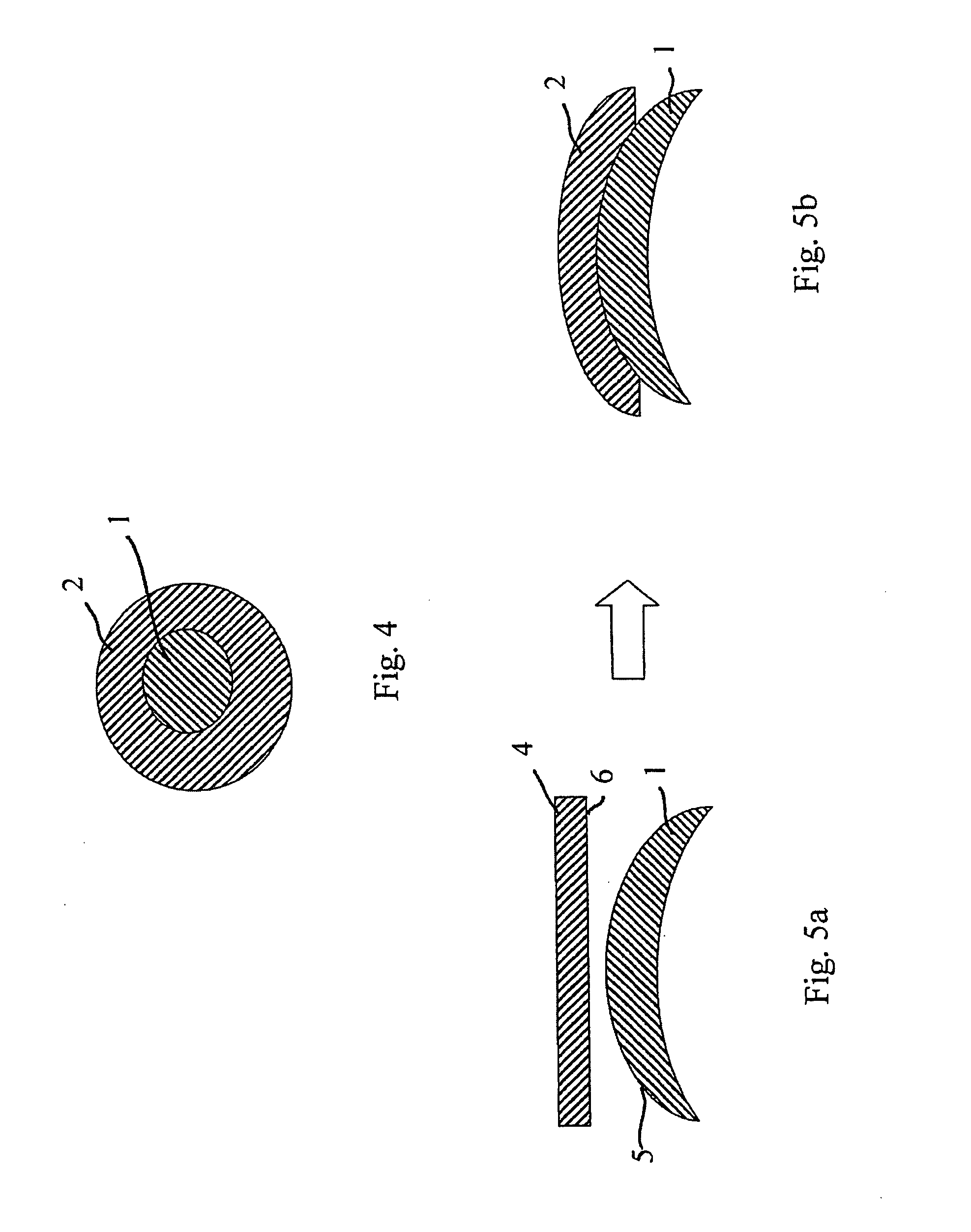

[0065] A ceramic sphere that consists of Y2O3 is directly connected to a low-TG glass by means of a “precise pressing” process. The glass surface is then aspherical. The selection of the ceramic and the glass is carried out such that, i.a., the partial dispersions are as optimally suitable as possible to avoid chromatic aberrations.

[0066] For this purpose, a ceramic sphere that consists of Y2O3 with a diameter of 3 mm is inserted into a suitable precision blank compression mold. A matching glass element that consists of N-SK57 glass (Schott) is applied, and the press is closed. The compression molds are highly precisely formed. In this case, the glass side of the form has an aspherical configuration. The sandwich is heated to 650° Celsius at a heating rate of 10K / minute, and it is pressed for 15 minutes there at a suitably high pressing pressure. The cooling is carried out at a speed of 30 K / minute.

[0067] The surface quality of the glass was sufficient so that no further surface f...

embodiment 2

[0068] By precision blank pressing (precise pressing), as described above based on embodiment 1, a hybrid lens that consists of a glass and an optoceramic is formed. Then, a polymer is sprayed on by means of an injection-molding process, which resulted in a hybrid lens comparable to that according to FIG. 2. The surfaces of the hybrid lens did not require any further finishing.

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| coefficient of thermal expansion | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com