Beam hinge fabricated self-resetting friction connecting node structure and connecting method

A friction connection and node structure technology, applied in building components, protective buildings/shelters, earthquake-proof, etc., can solve the problems of pouring difficulty, reduction, partial failure of the bearing capacity of the column, etc., to achieve strong recoverability and ensure stability. , the effect of preventing failure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0035] In order to better understand the present invention, the implementation manner of the present invention will be explained in detail below in conjunction with the accompanying drawings. At the same time, the specific implementation described here is only used to explain the present invention, not to limit the present invention.

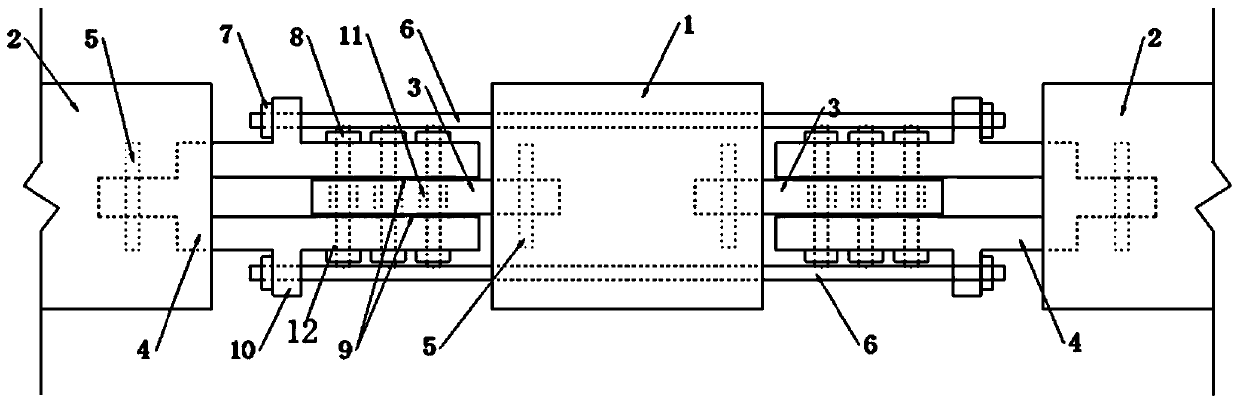

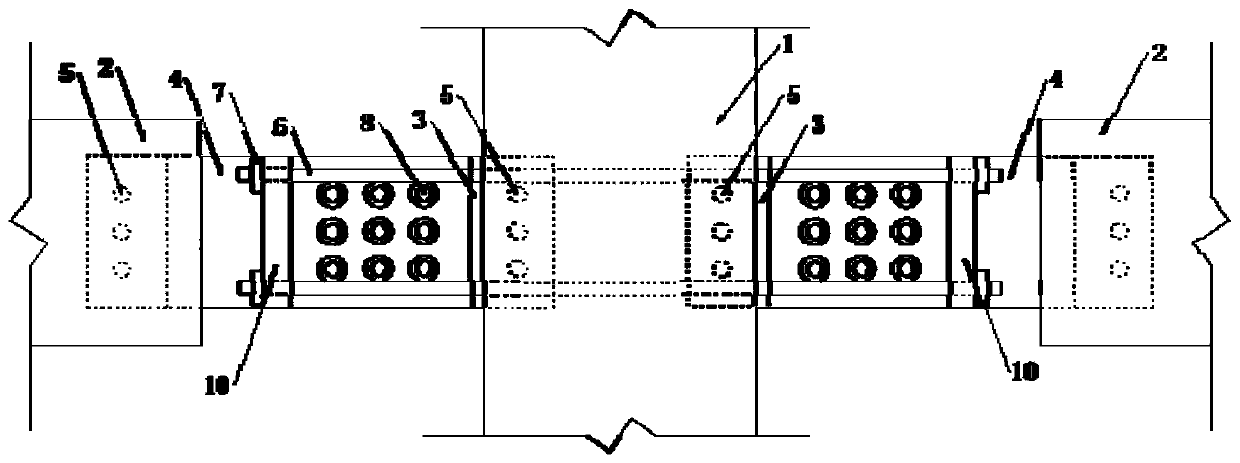

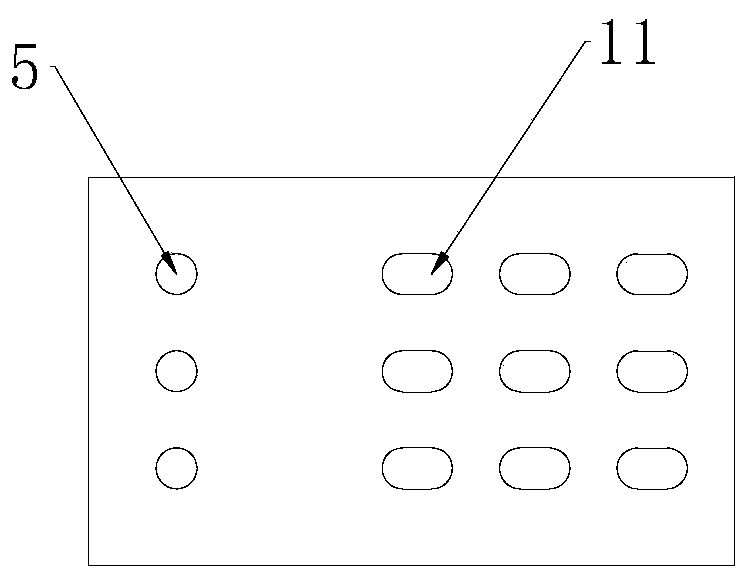

[0036] see Figure 1 to Figure 2 , a beam-hinge assembled self-resetting friction connection node structure, including a memory alloy rod 6, a first connecting piece 3 with one end embedded in a prefabricated column 1, and a second connecting piece 4 with one end embedded in a prefabricated beam 2, The other end of the second connecting piece 4 is provided with a groove arranged along the length direction of the second connecting piece 4, and the second connecting piece 4 is provided with a bolt hole 12, and the other end of the first connecting piece 3 is placed on the second connecting piece 4 In the groove, the first connecting piece 3 is pr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com