A kind of combustor transition piece structure and outlet side connection method

A connection method and burner technology, which are applied to combustion methods, combustion chambers, combustion equipment, etc., can solve the problems of complicated design of unstable sealing structure at the exit of the transition piece, complex design of the sealing structure, and stability of transition of transition pieces, etc. Achieve the effect of good installation stability, good sealing effect and wide applicability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

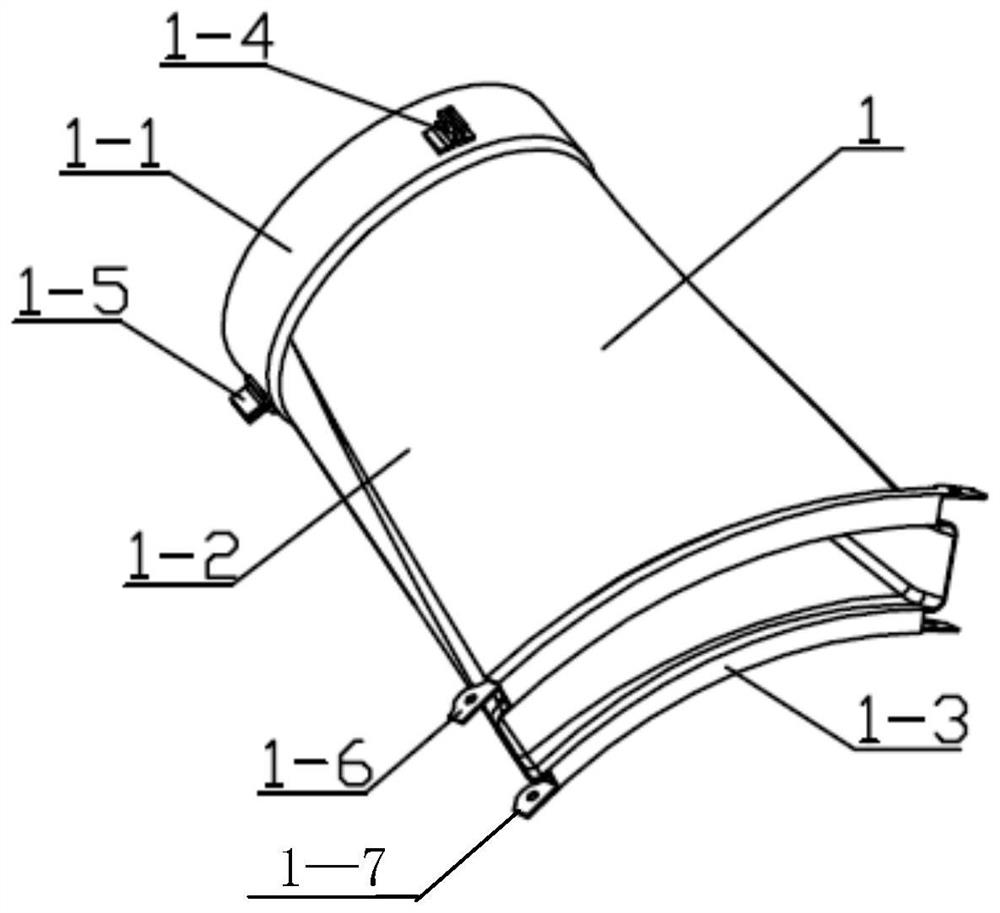

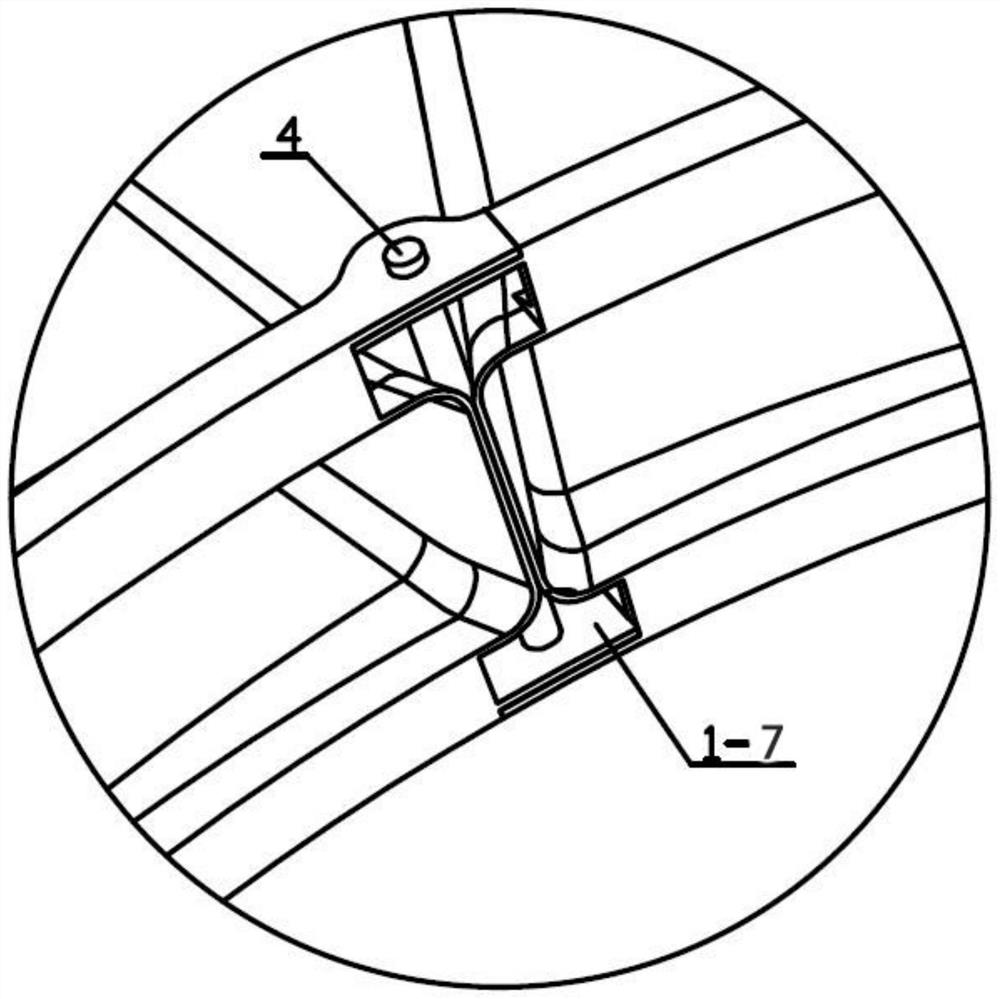

[0029] Such as figure 1 As shown, in this embodiment, a combustor tail tube structure is specifically provided, an important component of a gas turbine (aero engine) combustor, which includes a tail tube body 1-2, the tail tube body 1-2 As the main structure of the burner tail tube, a tail tube inlet support ring 1-1 is provided at one end of the tail tube body 1-2, and two tail tubes are provided in the circumferential direction of the tail tube inlet support ring 1-1 The inlet positioning structure (respectively the first tail tube inlet positioning structure 1-4, the second tail tube inlet positioning structure 1-5), through the tail tube inlet positioning structure for pre-positioning to ensure the correct installation of the combustor tail tube structure Preferably, in this embodiment, the tail cylinder inlet positioning structure is realized by a convex structure; the other end is provided with a tail cylinder outlet flange 1-3, and both sides of the tail cylinder outlet f...

Embodiment 2

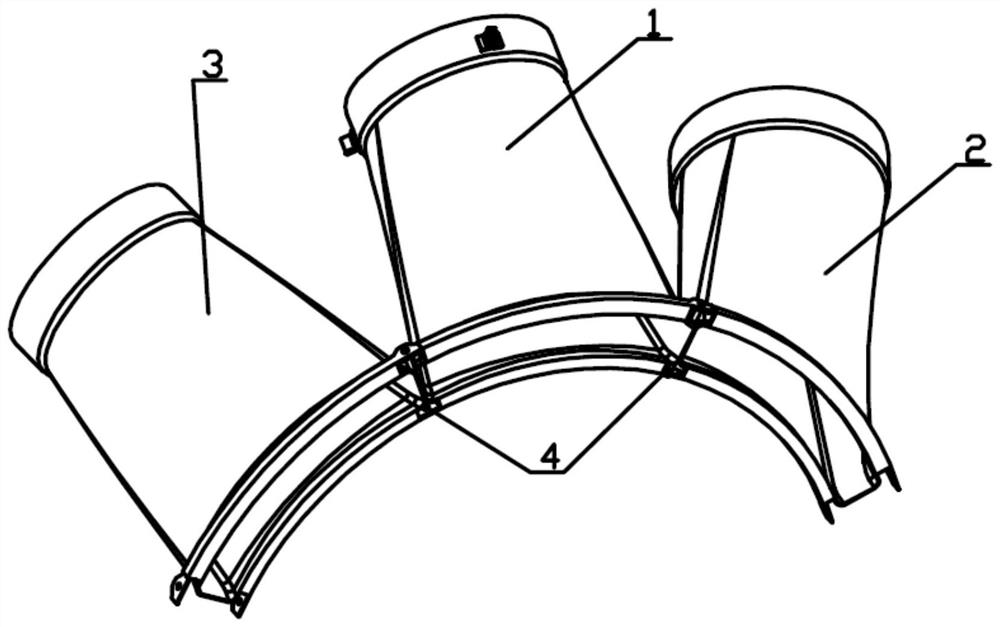

[0032] On the basis of Example 1, such as figure 2 As shown, in this embodiment, a method for connecting the outlet side of the combustor tail tube structure is specifically provided, and three of the above-mentioned combustor tail tube structures (respectively A combustor tail tube structure 1, B combustor tail Tube structure 2, C combustor tail tube structure 3), the outlet side connection method is as follows:

[0033] (1) Assemble each burner tail tube structure on the burner in turn. You can install one burner tail tube structure first, and then install the other two burner tail tube structures on both sides; three burners can also be installed. The tail tube structures are installed in sequence along the same lateral direction; after the installation of each combustor tail tube structure is completed, it is necessary to ensure that the first outlet connection structure and the second outlet connection structure of each combustor tail tube structure are arranged alternately;...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com