A Measuring Instrument for Oil-Water Interface Based on Photoelectric Sensing

An oil-water interface, photoelectric sensing technology, applied in the field of photoelectric sensing, can solve the problems of scaling of external components of measuring instruments, complicated replacement, catheter errors, etc., and achieves the effects of high explosion-proof level, wide detection range and easy installation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The technical solution of the present invention will be further described in detail below in conjunction with the accompanying drawings.

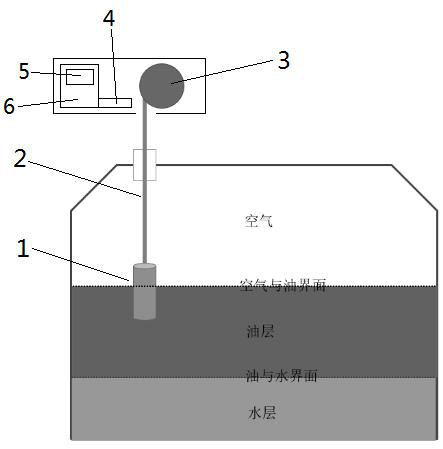

[0024] An oil-water interface measuring instrument based on photoelectric sensing includes a photoelectric sensor measuring head 1 , a tape measure 2 and a tape measure data reading and display mechanism 3 .

[0025] The photoelectric sensor measuring head 1 is set at one end of the tape measure 2, the tape measure 2 is set in the tape measure data reading and display mechanism, protrudes from the tape measure mechanism 3, records the rotation speed of the tape measure 2 through the encoder 4, and then calculates the tape measure by the single chip microcomputer 6 2 rotate the numerical value and show the length that tape measure protrudes by display screen 5. The encoder can measure the rotation speed or angle of the tape measure 2 on the fixed shaft, and the arc length formula can be used to calculate the rotation distance of the t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com