Current density detection composite board and online detection device for current density in battery

A technology of current density and composite board, which is applied in the direction of current density measurement, measuring devices, measuring electricity, etc., can solve the problems of increasing the cost of detection devices, achieve the effects of improving reliability, reducing manufacturing difficulty, and good interchangeability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

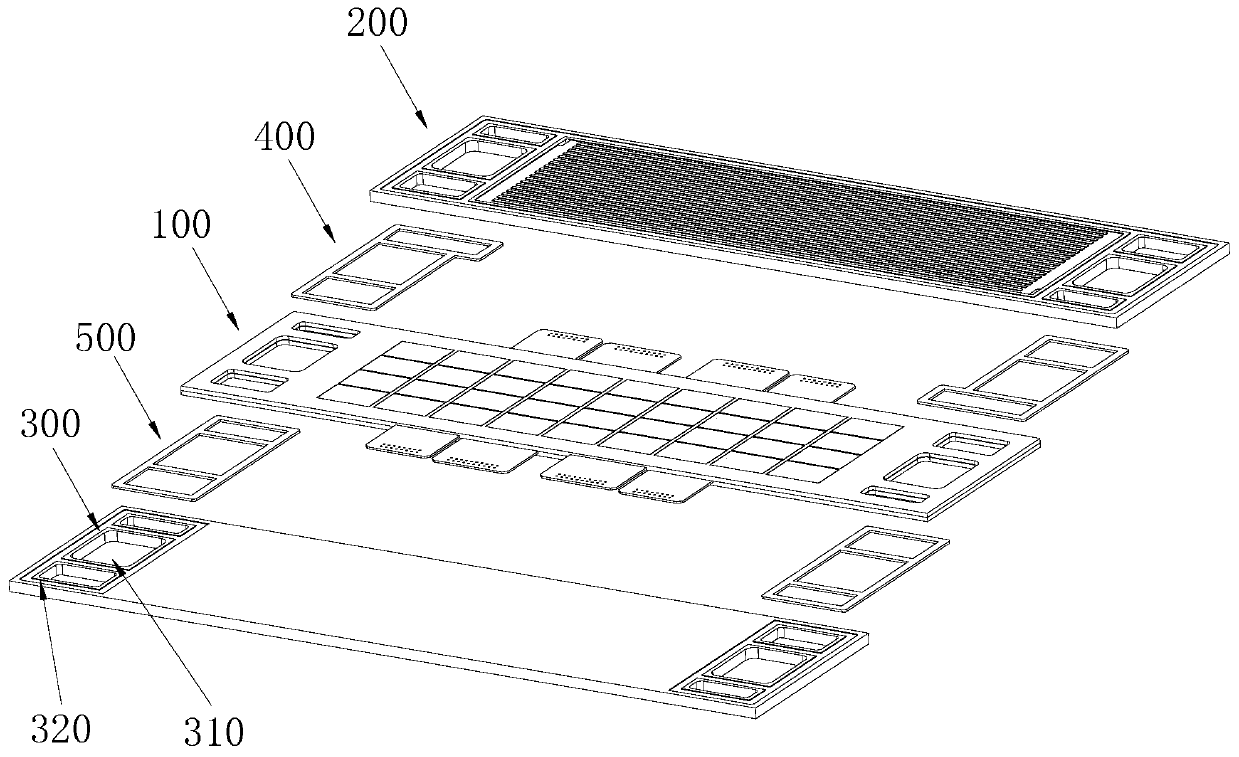

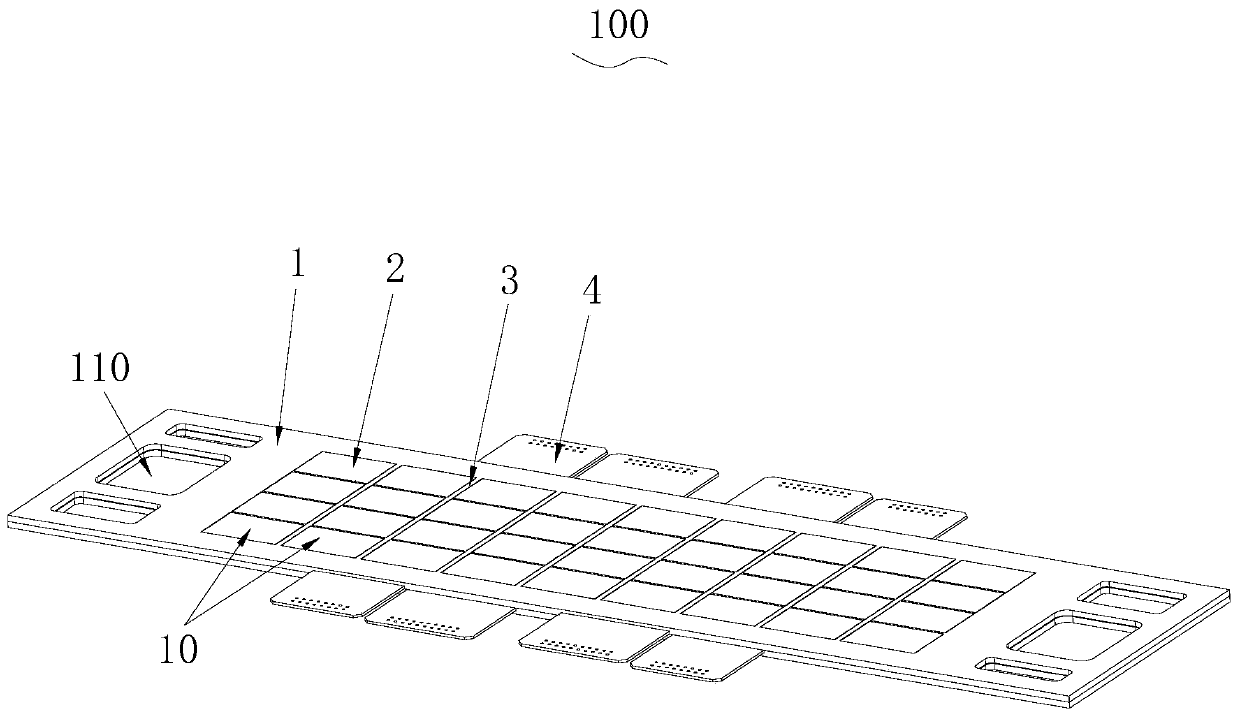

[0063] see Figure 6 to Figure 10 , the detection board 100 includes two first circuit boards 40 stacked, the first circuit board 40 has welding areas 41 distributed in a matrix, the welding areas 41 of the two first circuit boards 40 are distributed in one-to-one correspondence, the first circuit board 40 is provided with through holes 42 corresponding to the welding areas 41 one by one, and the through holes 42 of the two first circuit boards 40 are correspondingly connected; the first circuit board 40 is provided with circuit traces 43 correspondingly electrically connected to each welding area 41 , the first circuit board 40 is provided with a pin socket 44 at the end of the circuit trace 43; the board body 1 includes two insulating frames 10 stacked, each insulating frame 10 has a function for accommodating a first circuit board 40 Two first circuit boards 40 are respectively embedded and clamped between two insulating frames 10, and the insulating frame 10 is provided with...

Embodiment 2

[0076] The technical features of the current density detection composite board 1000 in this embodiment are basically the same as those of the current density detection composite board 1000 in Embodiment 1, the difference is that in this embodiment, please refer to Figure 11 , the standard resistor 22 is placed outside the board body 1 . Specifically, the conductive sheets 21 are separated by two second circuit boards 60, the two second circuit boards 60 are respectively embedded in the board body 1 and at least partly exposed outside the board body 1, and the two conductive sheets 21 are connected to the two second circuit boards respectively. The two circuit boards 60 are electrically connected, and each standard resistor 22 is respectively pasted on the part of the second circuit board 60 exposed outside the board body 1 .

[0077] In addition, the board body 1 can be composed of two insulating frames. At this time, the two second circuit boards 60 are attached to each othe...

Embodiment 3

[0079] The technical features of the current density detection composite board 1000 in this embodiment are basically the same as those of the current density detection composite board 1000 in Embodiment 1, the difference is that in this embodiment, please refer to Figure 12 , the plate body 1 is a single-layer structure, a second insulating member 23 is arranged between the two conductive sheets 21, and the standard resistor 22 is arranged on the side edges of the two conductive sheets 21; or, the standard resistor 22 is embedded in the second insulating member 23 or the standard resistor 22 is set on the third external circuit board, and the two ends are electrically connected to the two conductive sheets 21 through the second wire respectively; the two ends of the standard resistor 22 are connected with the first wire 24, and the external controller passes the first wire 24 is electrically connected with the standard resistance 22 to measure the voltage drop across the stand...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com