Curved surface track robot system for practical training and assessment method thereof

A robot system and robot technology, applied in the direction of instruments, simulators, educational appliances, etc., can solve problems such as inability to master complex robot movements, neglect, and inability to accurately control the movement of tools, and achieve the effect of improving programming and operation capabilities.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

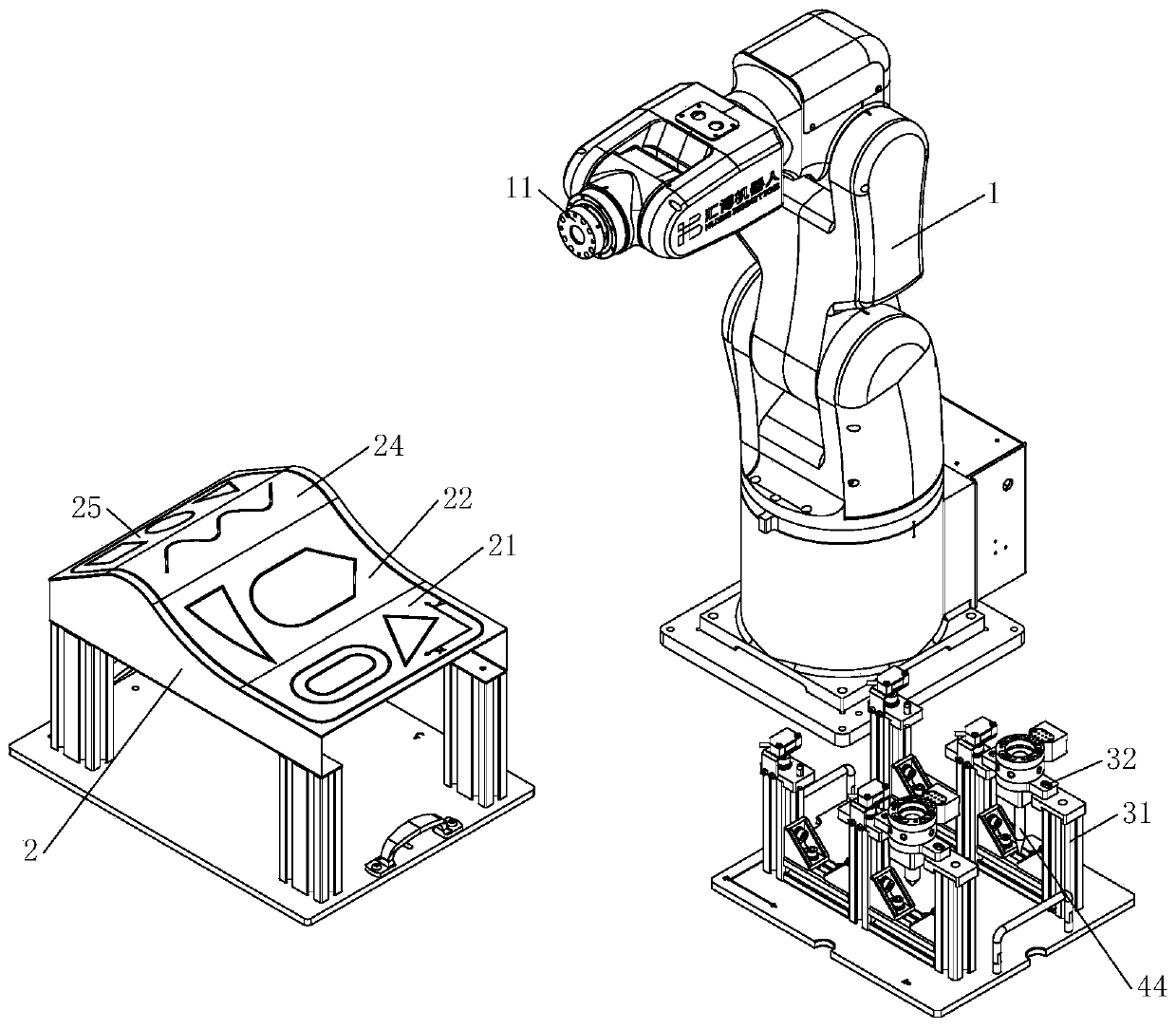

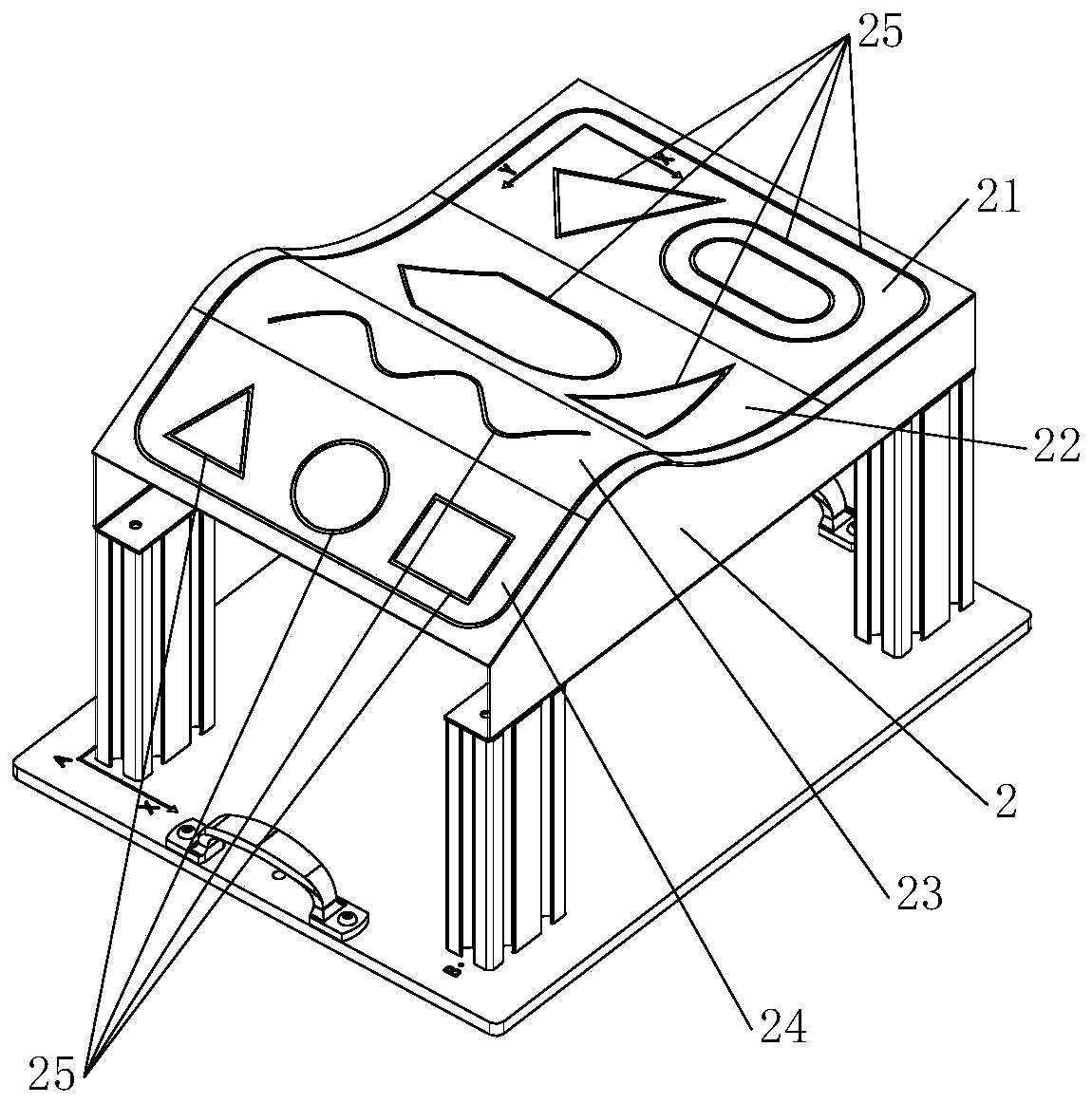

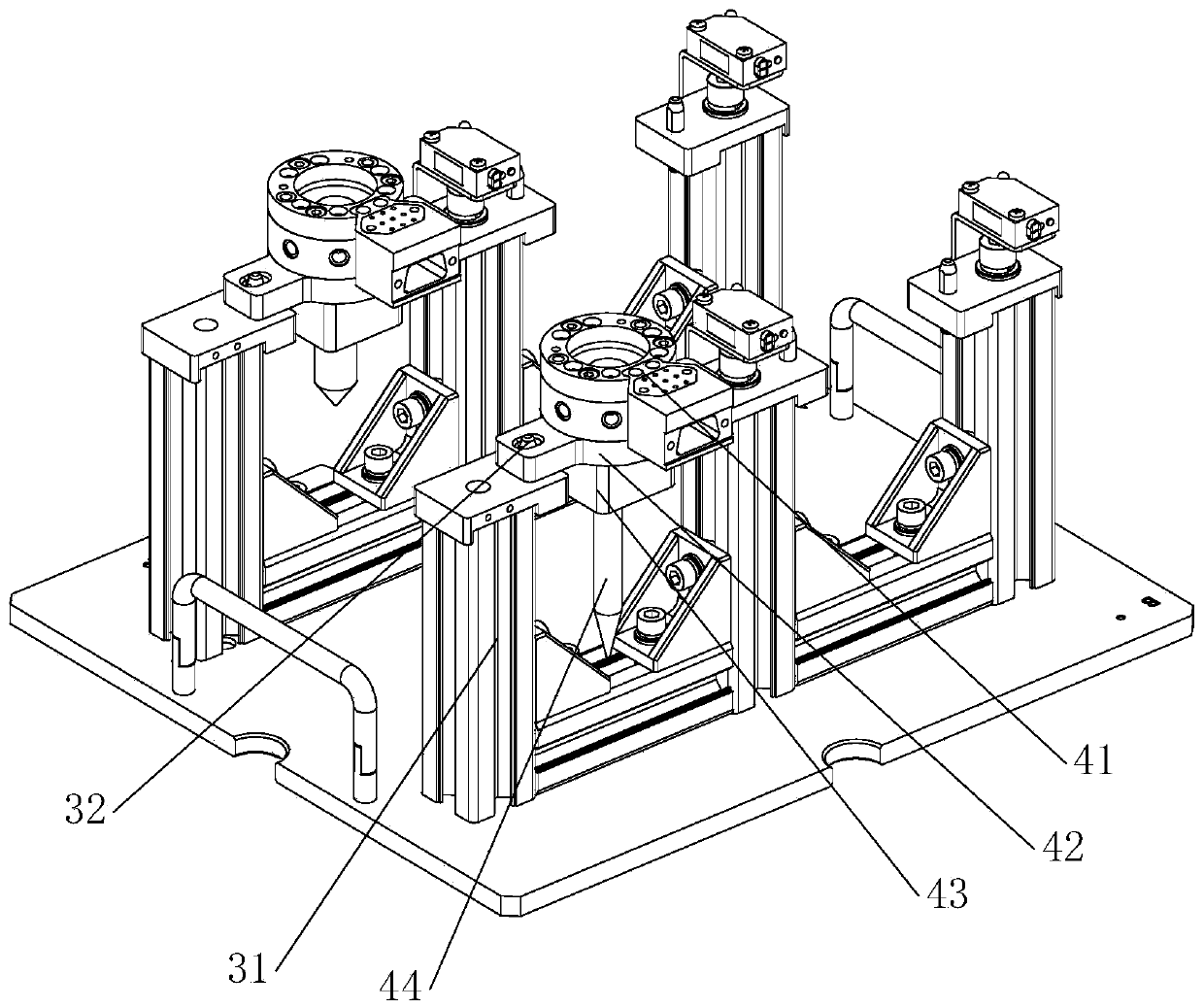

[0043] Such as Figure 1 to Figure 4 As shown, the curved surface trajectory robot system for training includes a robot 1, the end of which is equipped with a male quick-change tool tray 11; Curved surface tracing plate 2, curved surface tracing plate 2 is a curved panel, and the surface of curved surface tracing plate 2 is provided with a plurality of tracing tracks 25; Tracing pen 44, and one end of tracing pen 44 is equipped with female quick-change tool plate 41 ; The tool rack 31, the tracing pen 44 is inserted in the tool rack 31 freely.

[0044] Part of the tracing track 25 on the curved surface tracing board 2 is set along the curved surface, and some are not on the curved surface, so as to realize the training of the plane trajectory and the curved surface trajectory, and greatly improve the students' ability to program and operate the complex curved surface trajectory.

[0045] Concretely, the tool positioning plate 42 is housed on the female quick-change tool tray ...

Embodiment 2

[0055] On the basis of the first embodiment above, it also includes a tracing seat 43, which is fixed on the female quick-change tool tray 41, and a sliding hole is provided on the tracing seat 43, and a tracing pen 44 is movably inserted in the tracing seat 43 in the sliding hole; return spring, a return spring is installed between the tracing pen 44 and the tracing seat 43, and the returning spring is located in the sliding hole; the detection sensor, the detection sensor is installed in the sliding hole, and is located between the tracing seat 43 and the Between the tracer pen 44 and not interfering with the return spring, the detection sensor is a proximity switch or a travel switch, and the detection sensor is used to detect whether the tracer pen 44 moves toward the tracer seat 43 .

[0056] During training, if the operator controls the tracing pen 44 to trace the tracing track 25, the tracing pen 44 contacts the curved surface tracing plate 2 and moves to the detection s...

Embodiment 3

[0058] On the basis of the first embodiment above, it also includes a first tracing wire, the first tracing wire is connected with the tracing pen 44, a second tracing wire, the second tracing wire is connected with the curved surface tracing board 2, and the tracing When the pen 44 is in contact with the curved surface tracing board 2, the first tracing wire communicates with the second tracing wire.

[0059] During assessment or training, if the tracer stylus 44 is in contact with the curved surface tracer board 2, the first tracer wire and the second tracer wire are connected to generate an electrical signal, thereby indicating that the operation is unqualified.

[0060] It is necessary to ensure the conduction between the tracing pen 44 and the curved tracing board 2 . Both the tracing pen 44 and the curved surface tracing board 2 are made of metal, the tracing pen 44 can be connected with the robot 1, the robot 1 can be connected with the workbench, and the curved surface...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com