Preparation method of loudspeaker diaphragm, loudspeaker diaphragm and loudspeaker monomer

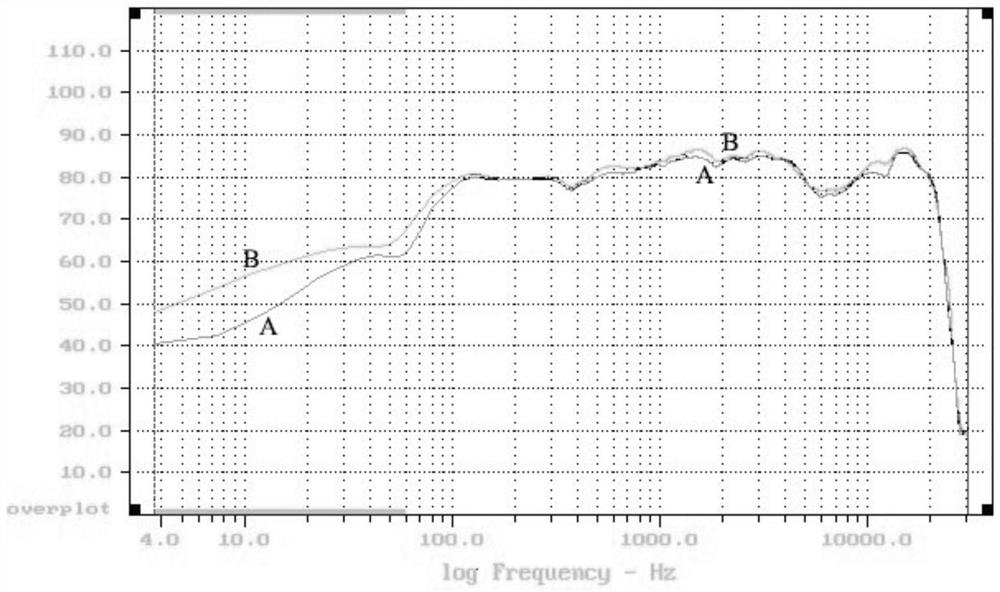

A loudspeaker and monomer technology, which is applied to ceramic material diaphragms, cellulose material diaphragms, sensors, etc., can solve the problems of uneven force, large distortion, and easy deformation of the diaphragm, so as to reduce the split vibration, The effect of large damping and enhanced strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0033] The invention proposes a method for preparing a loudspeaker diaphragm, aiming at solving the problem of large distortion and easy deformation of the existing loudspeaker diaphragm due to uneven stress on the diaphragm in the short axis direction.

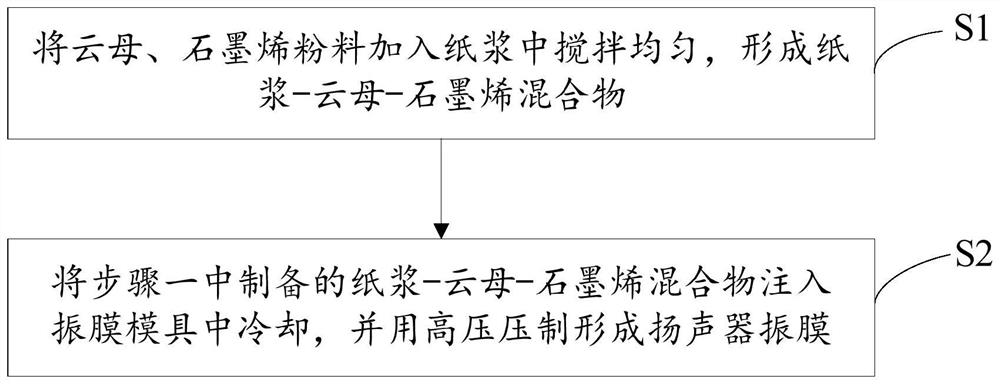

[0034] Please refer to figure 1 , the invention provides a method for preparing a loudspeaker diaphragm, comprising the following steps:

[0035] Step S1, adding mica and graphene powder into the pulp and stirring evenly to form a pulp-mica-graphene mixture.

[0036] Step S2, pouring the pulp-mica-graphene mixture prepared in step S1 into a diaphragm mold to cool, and pressing it with high pressure to form a loudspeaker diaphragm.

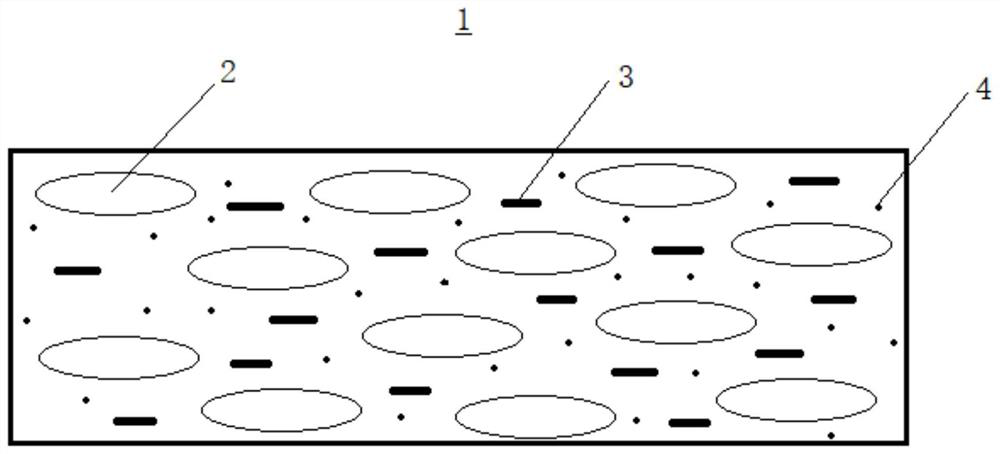

[0037] Specifically, the Young's modulus E of mica is larger than that of pulp. Adding mica to pulp can change the rigidity of the speaker diaphragm, without generating or reducing split vibration, and reducing distortion; after adding mica, the resistance of the speaker diaphragm can be improved...

Embodiment 1

[0045] Add 10g of flaky mica and 1g of graphene powder to 100g of pulp, and stir for 30min until the flaky mica, graphene powder and pulp are evenly mixed. The uniformly mixed pulp-mica-graphene mixture is injected into the diaphragm mold to cool, and high pressure is applied to the diaphragm mold through multiple directions to form a loudspeaker diaphragm in the diaphragm mold.

Embodiment 2

[0047] Add 12g of mica flakes and 2g of graphene powder into 100g of pulp, and stir for 30 minutes until the mica flakes, graphene powder and pulp are evenly mixed. The uniformly mixed pulp-mica-graphene mixture is injected into the diaphragm mold to cool, and high pressure is applied to the diaphragm mold through multiple directions to form a loudspeaker diaphragm in the diaphragm mold.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com