Profile steel welding robot system and working method thereof

A welding robot and robot technology, applied in welding equipment, auxiliary welding equipment, welding/cutting auxiliary equipment, etc., can solve the problems of lowering production efficiency and welding quality, such as breakdown, undercut, and no existing section steel welding device and method and other issues to achieve the effect of ensuring safety

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

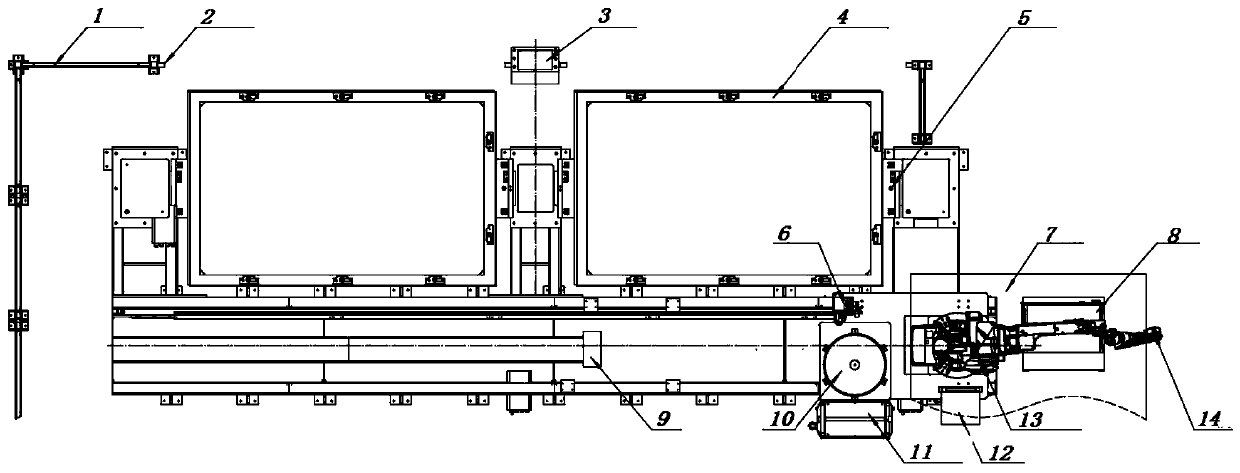

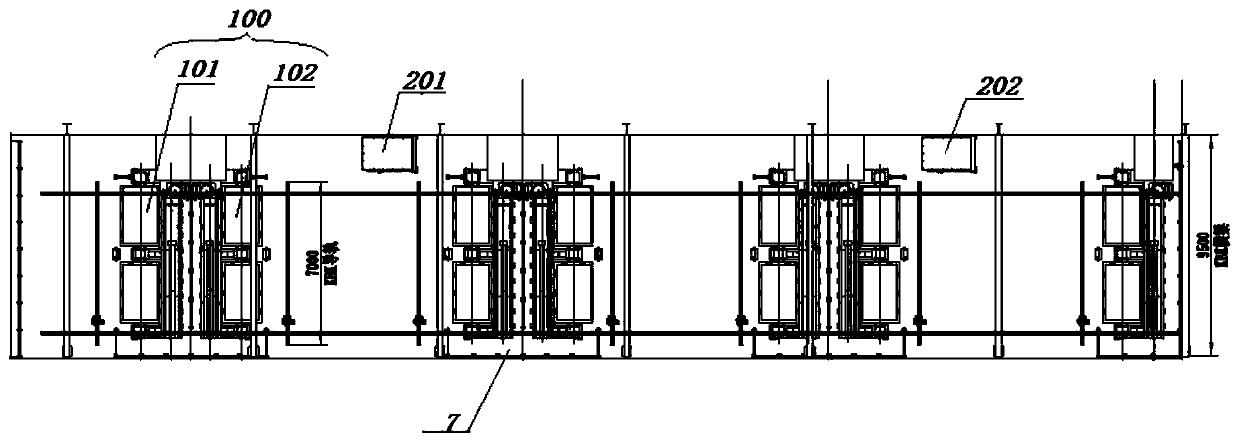

[0038] Please refer to figure 1 , the present embodiment discloses a steel welding robot 13 system, including a plurality of steel robot welding devices and a numerical control module connected to a plurality of steel robot welding devices, each steel robot welding device includes a safety protection mechanism, a welding robot 13, a robot Sliding table 9, welding auxiliary mechanism and laser sensor 14 installed in welding robot 13, welding robot 13, robot sliding table 9 and welding auxiliary mechanism are all placed on the inside of the safety protection mechanism, welding robot 13 is slidingly connected to robot sliding table 9; this implementation The numerical control module in the example is located in the robot control cabinet 8.

[0039] A plurality of welding robots 13 are placed in a constant temperature environment.

[0040] The robot is equipped with a welding torch.

[0041] Each of the welding robots 13 and each laser sensor 14 is connected to a numerical contr...

Embodiment 2

[0071] Embodiment 2 discloses a working method of a section steel welding robot 13 system, using the section steel welding robot 13 system as described in embodiment 1, comprising the following steps:

[0072] After the skeleton section steel is cut and blanked, the single-axis head and tail positioner tooling clamps the workpiece to be welded;

[0073] Make an appointment to start the welding robot 13;

[0074] After receiving the appointment signal, the robot enters the station and starts welding;

[0075] The single-axis head and tail positioner cooperates with the robot to flip and shift the workpiece, and the robot completes the welding;

[0076] After the welding program is completed, the robot resets and waits; or moves into the second station welding through the robot sliding table 9 .

[0077] The two section steel robot welding devices of each group of robot welding workstations 100 can work independently or alternately.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com