Marine I-shaped sandwich plate laser welding tool and using method thereof

A laser welding, sandwich panel technology, applied in laser welding equipment, welding equipment, welding equipment and other directions, can solve the problem of unsolved web fixing problems, improve defects, large size of magnetic welding fixtures, etc., to improve work efficiency and The effect of welding quality, reasonable design and convenient operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

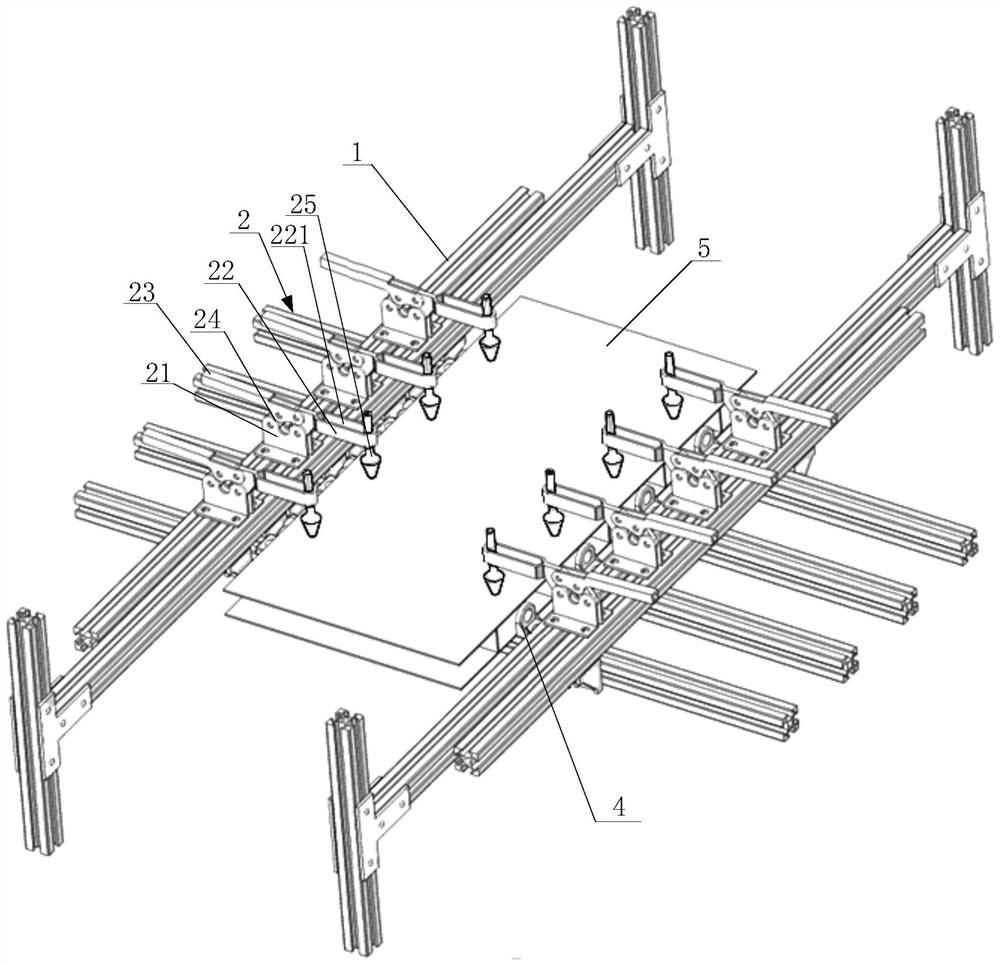

[0035] According to the attached figure 1 and figure 2 , give a preferred embodiment of the present invention, and give a detailed description, so that the functions and characteristics of the present invention can be better understood.

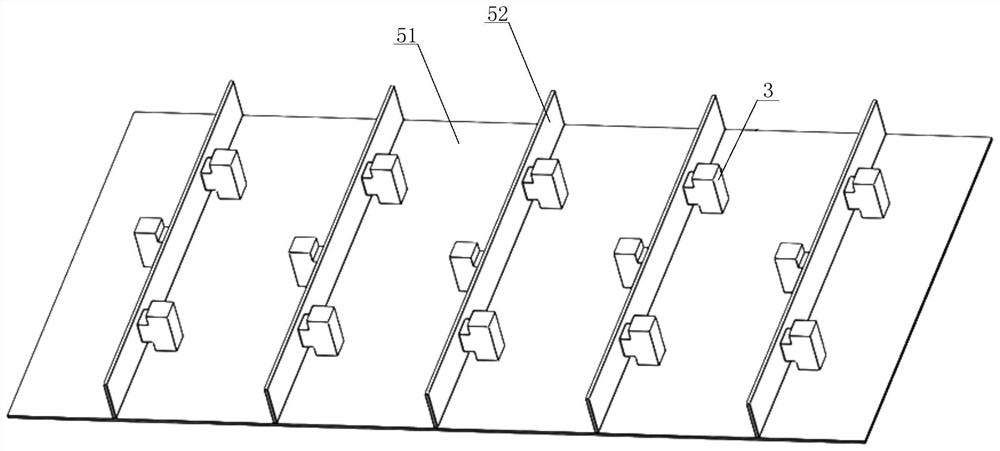

[0036] see figure 1 and figure 2 , a kind of marine I-type sandwich plate laser welding frock of the embodiment of the present invention comprises an outer panel fixing device and an inner web support assembly, the outer panel fixing device includes an outer frame 1 and a clamp set; the clamp set includes a plurality of The horizontal clamps 2 are divided into two rows and arranged oppositely along the first direction and screwed on the outer frame 1; the internal web support assembly includes a plurality of special-shaped magnets 3, and the cross-section of the special-shaped magnets 3 is convex.

[0037] Horizontal fixture 2 comprises a support 21, a depression bar 22, a handle 23, a connecting rod 24 and a pressure head 25; Support 21...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com