Pneumatic (electric) wrench for connecting straight thread sleeves and reinforcing steel bars

A technology of straight thread sleeves and steel bars, applied in the direction of motor tools, manufacturing tools, etc., can solve the problems of high operating surface requirements, reduced quantity, low labor efficiency, etc., to reduce construction costs, ensure safe construction, and reduce risks Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

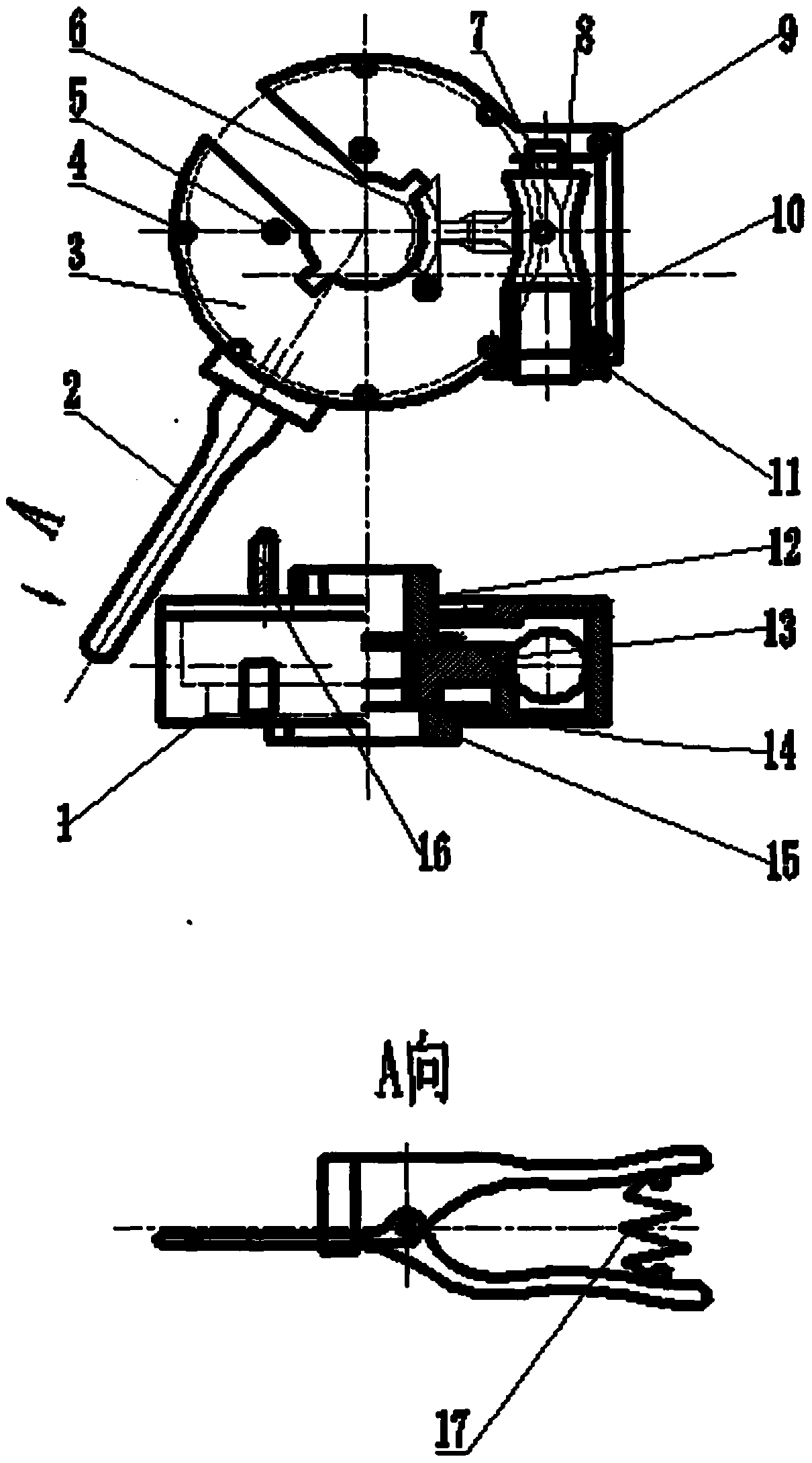

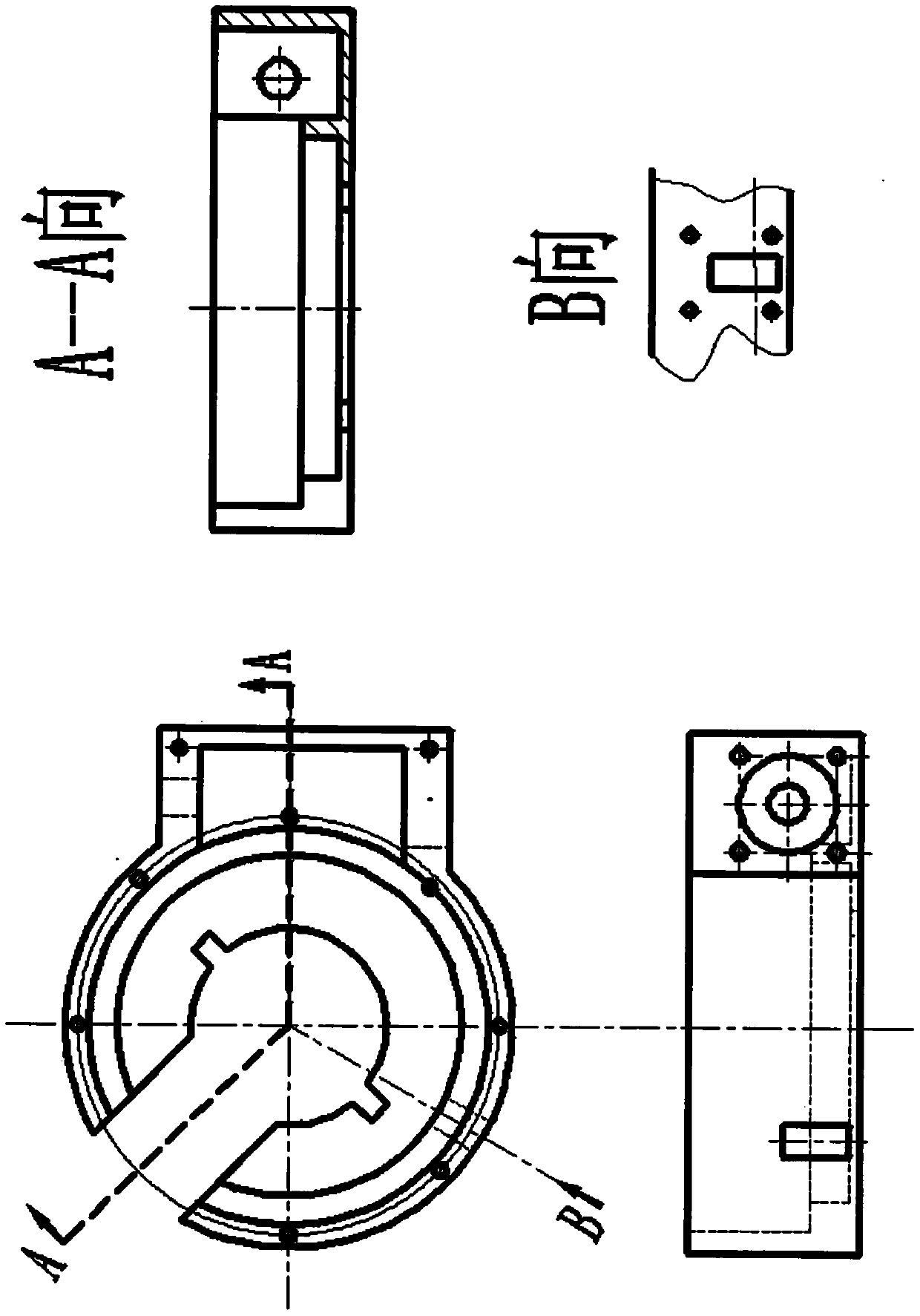

[0024] The technical solutions of the present invention will be described in further detail below with reference to the accompanying drawings and embodiments.

[0025] specific steps

[0026] Step 1: Open your mouth

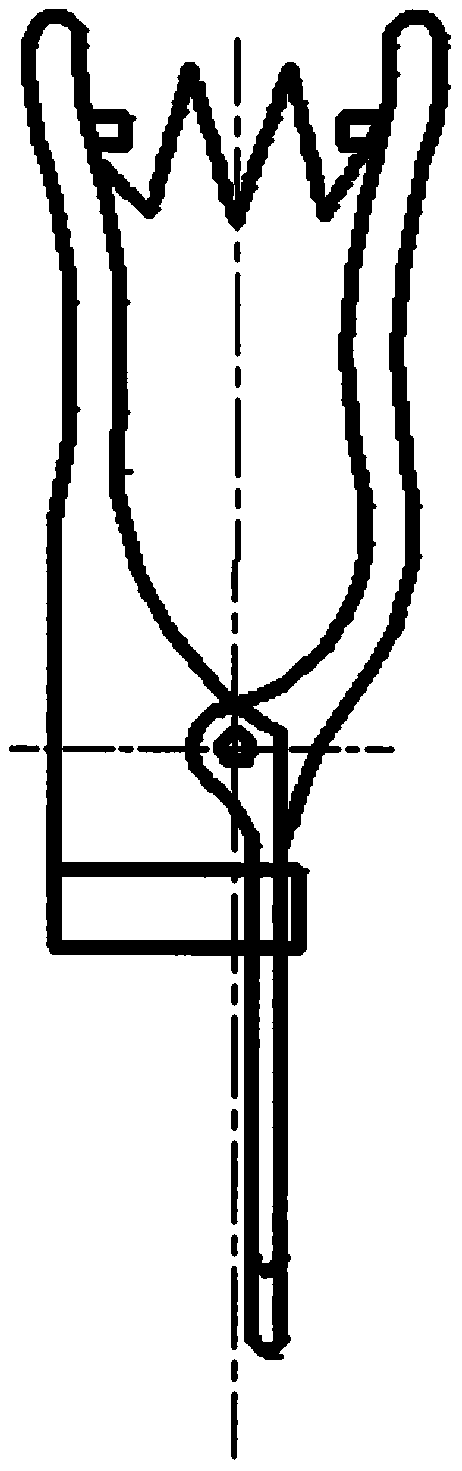

[0027] When opening the mouth, hold the handle 2 and the handle of the shift fork 14 with the left hand, press the two pincers to the inside, compress the spring 17, and the end of the shift fork 14 moves down. Under the action of the spring 16, the pressure plate 12 moves down, pushing the card The head 6 moves down and separates to the sides to open the opening;

[0028] Step 2: Clamp the workpiece (rebar or link sleeve)

[0029] Move the tool from the side direction of the diameter of the workpiece, put the workpiece into the center of the tool from the opening, loosen your left hand, and make the shift fork 14 rotate around the fixed connection shaft under the action of the spring 17. Move, hold up the sliding bracket 15, and the sliding bracket 15 jacks u...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com