A low-temperature and environmentally friendly black glass paste with high optical density

A technology of black glass and glass paste, applied in the field of glass paste, can solve the problems of restricting the use and development of glass paste, poor covering power of glass paste, high temperature of glass paste, etc., and achieve excellent acid and alkali resistance, glaze Good surface gloss and good sphericity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

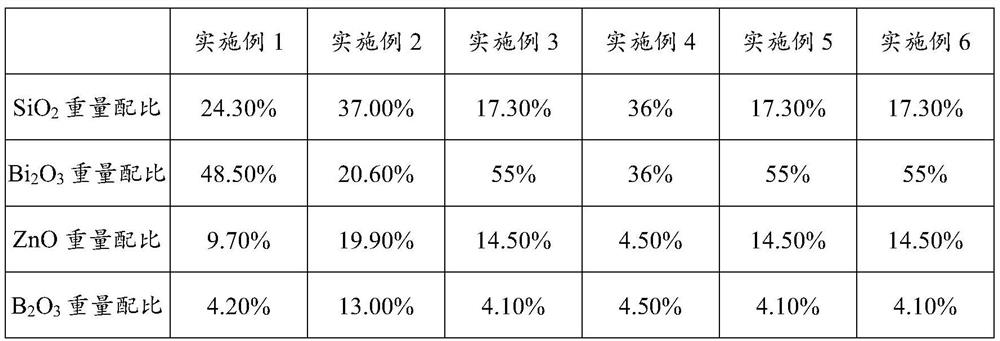

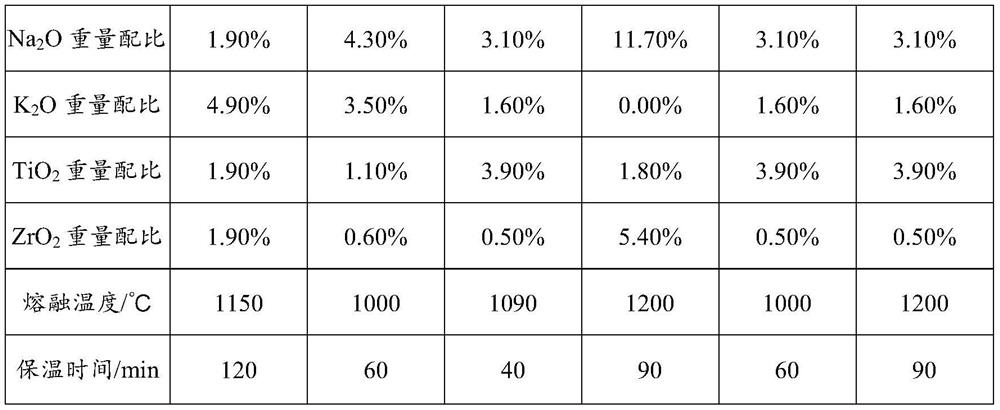

[0029] Preparation method of cullet base material:

[0030] S1.1 Mixing: Weigh SiO according to the weight ratio shown in Table 1 2 、Bi 2 o 3 , ZnO, B 2 o 3 、Na 2 O, K 2 O, TiO 2 , ZrO 2 , and placed in a mixer for mixing, and mixed evenly to obtain a mixture;

[0031] S1.2 Melting: Put the mixture obtained in step S1.1 into a crucible and put it into a muffle furnace for melting, the melting temperature is 1000°C-1200°C, and the holding time is 40-120min to obtain glass liquid;

[0032] S1.3 Ice-water quenching: the glass liquid obtained in the above step S1.2 is quenched with deionized ice-water, and dried to obtain a cullet base material.

[0033] Table 1

[0034]

[0035]

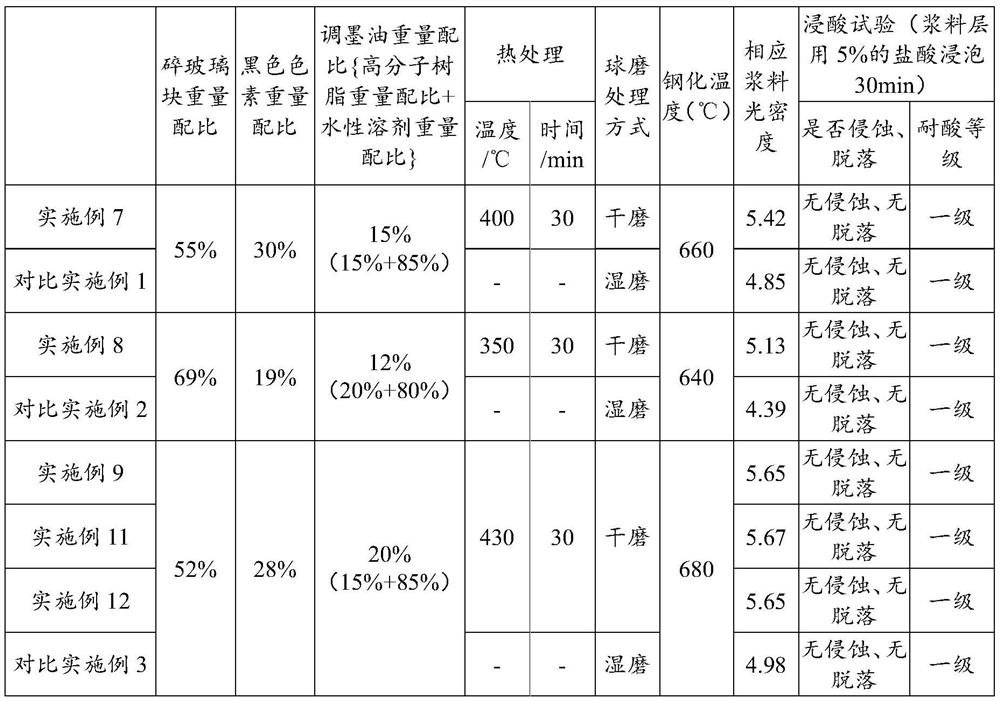

Embodiment 7

[0037] Embodiment 7 selects the cullet base material prepared in embodiment 1 for use;

Embodiment 8

[0038] Embodiment 8 selects the cullet base material prepared in embodiment 2;

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| optical density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com