Synthesis method of phosphosilicate white light emission fluorescent powder

A technology of phosphosilicate and synthesis method, which is applied in chemical instruments and methods, luminescent materials, climate sustainability, etc., can solve the problems of short excitation range, insufficient fluorescent pink component, easy light color drift, etc. The effect of emission intensity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

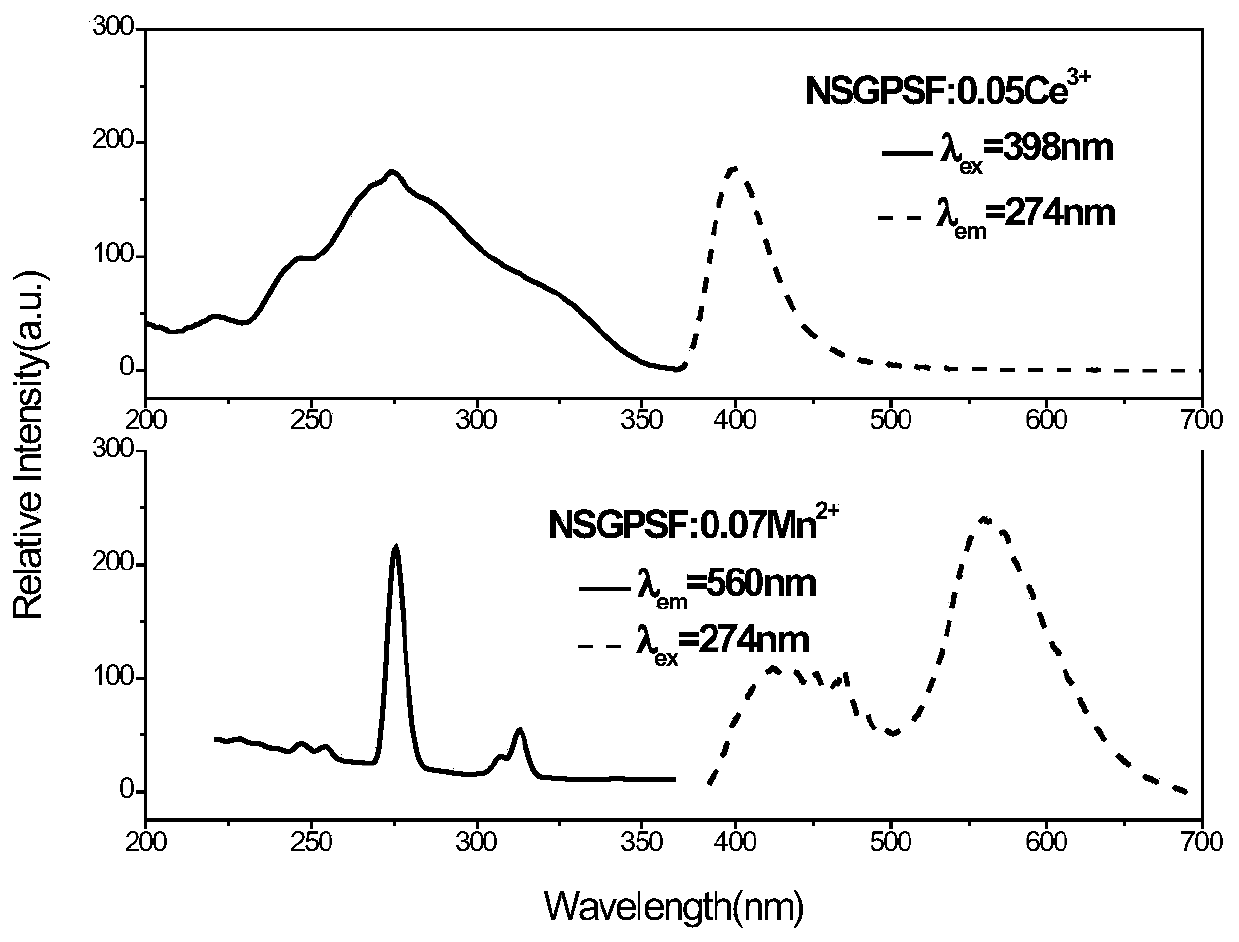

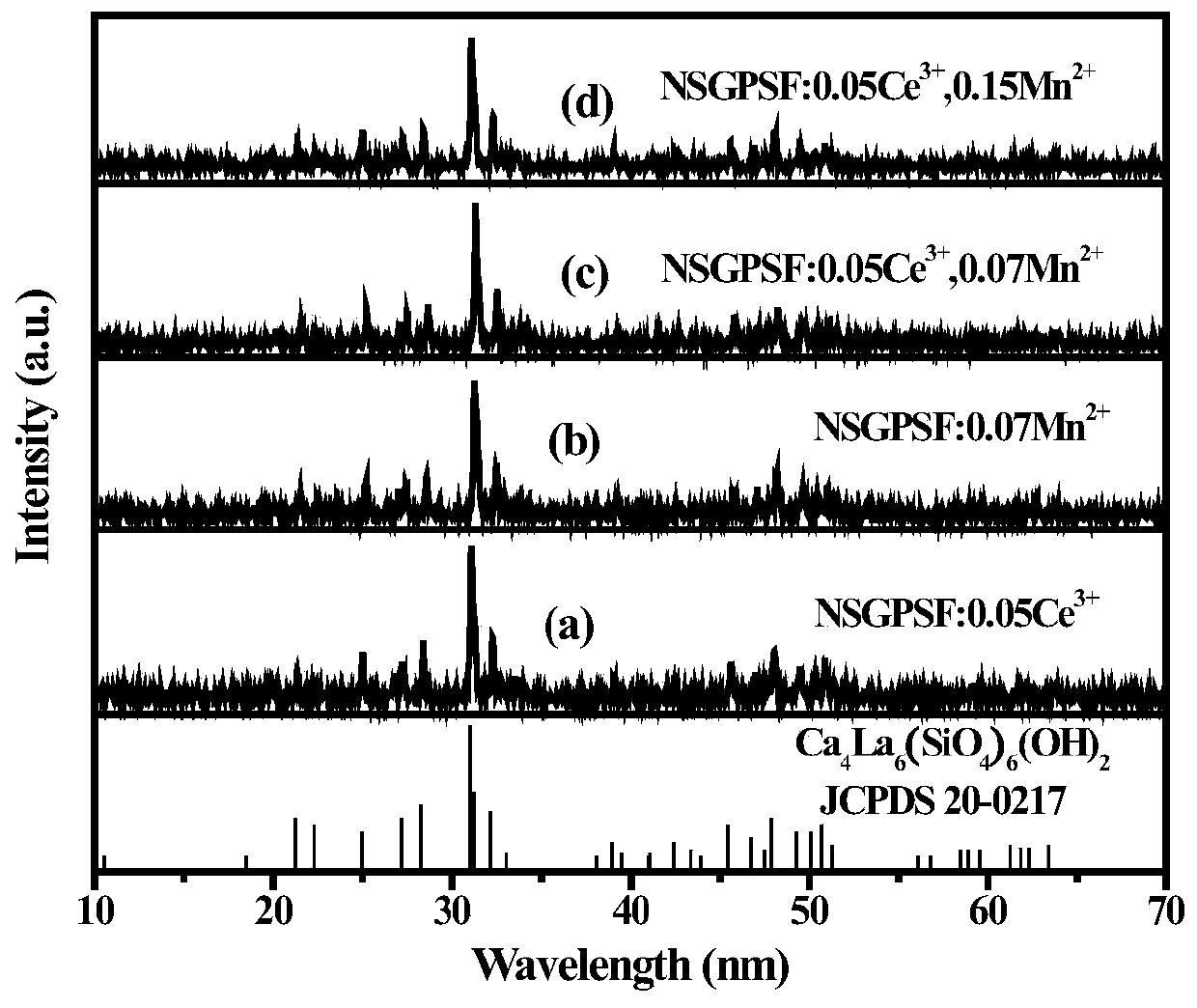

Method used

Image

Examples

Embodiment 1~4

[0021] Weigh the drug according to the raw material ratio in Table 1, mix the drug evenly in an agate mortar, and grind for 30 minutes; put the evenly ground sample into a corundum crucible, place the crucible in a muffle furnace, and grind it in an air atmosphere , 600°C pre-burning for 4 hours for precursor treatment, the heating system is 10min → 450°C → 20min → 450°C → 15min → 600°C → 240min → 600°C → end, to obtain the precursor mixed oxide; the precursor mixed oxidation Take out the material, put it in an agate mortar and grind it evenly again, and the grinding time is 10 minutes. Place the ground precursor in a corundum crucible, put it into a tube furnace, and react at 1000°C for 4h under a reducing atmosphere (the temperature is 1000-1100°C, and the reaction time is 3-4h, for comparison, In Examples 1-4, the temperature is uniformly 1000° C., and the reaction time is 4 h). After cooling to room temperature, take out and grind evenly to obtain a phosphosilicate white l...

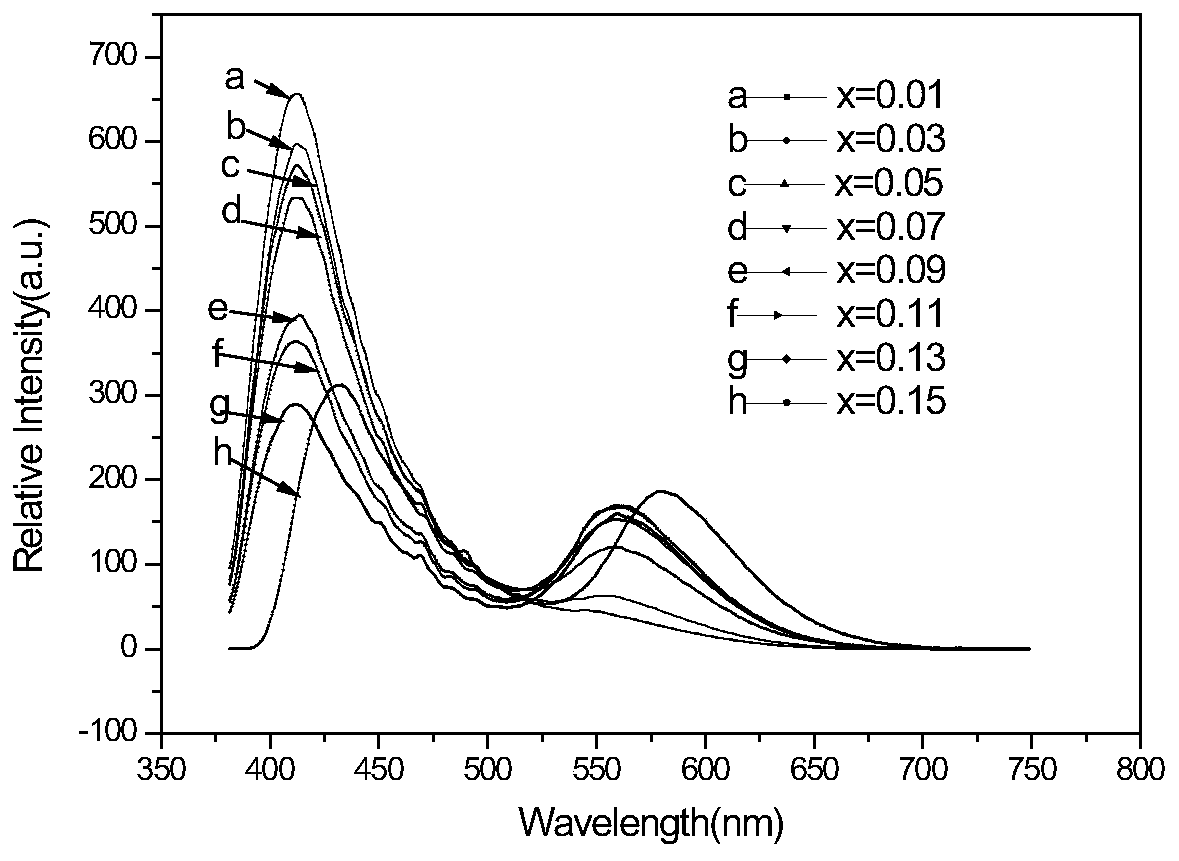

Embodiment 5~13

[0029] Weigh the drug according to the raw material ratio in Table 2, mix the drug evenly in an agate mortar, and grind for 30 minutes; put the evenly ground sample into a corundum crucible, place the crucible in a muffle furnace, and grind it in an air atmosphere Pre-burn at 600°C for 4 hours for precursor treatment, the heating system is 10min → 450°C → 20min → 450°C → 15min → 600°C → 240min → 600°C → end, to obtain the precursor mixed oxide; mix the precursor The oxides were taken out, placed in an agate mortar and ground again evenly, and the grinding time was 10 minutes. Put the ground precursor in a corundum crucible, put it into a tube furnace, and react at 1000°C for 4h under a reducing atmosphere (where the temperature is 1000-1100°C, and the reaction time is 3-4h, for the convenience of comparison, implement In Example 1-4, the temperature is uniformly 1000° C., and the reaction time is 4 h). After cooling to room temperature, take it out and grind it evenly to obtai...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com