Ultraviolet-resistant flame-retardant multifunctional coating fabric finishing agent and finishing process

A technology of multi-functional coating and fabric finishing agent, which is applied in the direction of flame-retardant fibers, fiber treatment, textiles and papermaking, etc., can solve the problem of not having both anti-ultraviolet performance and flame-retardant properties, and the difference in the anti-ultraviolet effect of fabrics. Human life and property safety and other issues, to achieve the effect of maintaining chemical balance, stable quality, and reducing surface tension

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

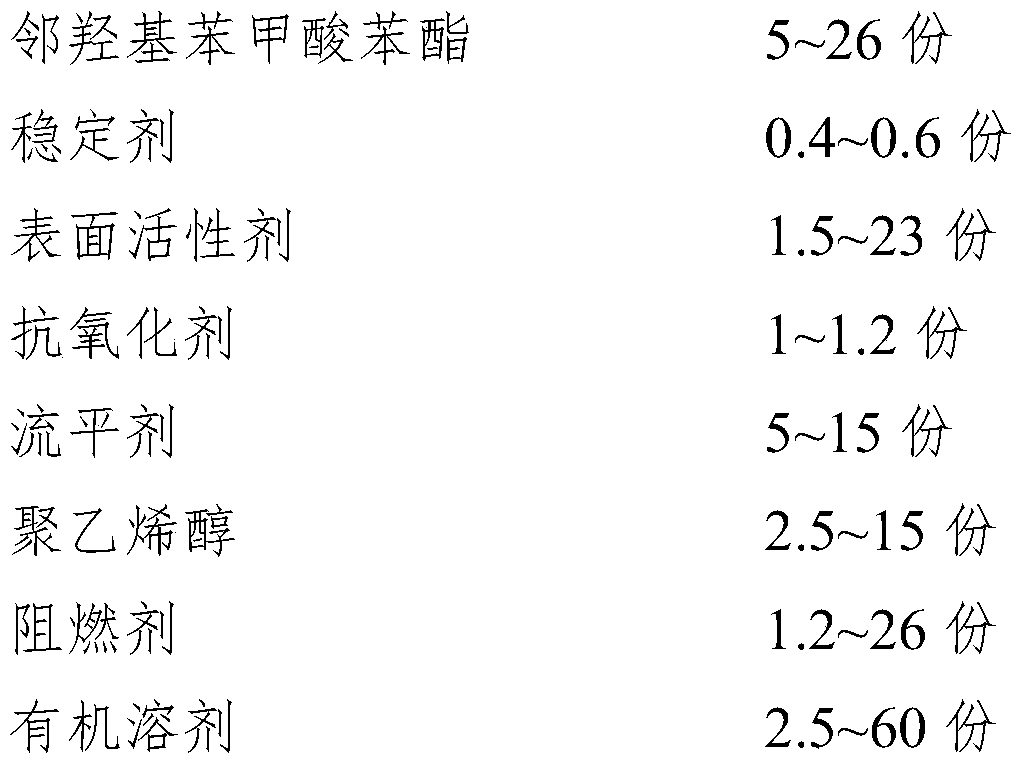

Method used

Image

Examples

Embodiment 1

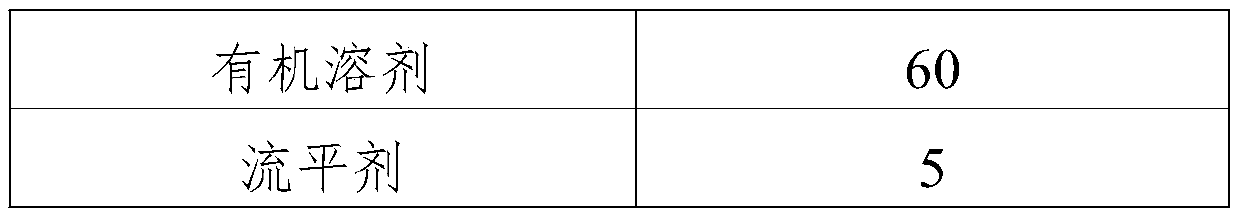

[0027] An environment-friendly textile low-temperature coating is disclosed in Example 1, and its formulation is shown in Table 2.

[0028] The formula table of table 2 embodiment 1

[0029] components Content (parts by weight) Phenyl o-hydroxybenzoate 20 Surfactant 1.5 Antioxidants 1 polyvinyl alcohol 10 flame retardant 5 Organic solvents 60 leveling agent 5 stabilizer 0.4

Embodiment 2

[0031] An anti-ultraviolet, flame-retardant multifunctional coating is disclosed in Example 2, and its formulation is shown in Table 3.

[0032] The formula table of table 3 embodiment 2

[0033]

[0034]

Embodiment 3

[0036] An anti-ultraviolet, flame-retardant multifunctional coating is disclosed in Example 3, and its formulation is shown in Table 4.

[0037] The formula table of table 4 embodiment 3

[0038] components Content (parts by weight) Phenyl o-hydroxybenzoate 20 Surfactant 1.5 Antioxidants 1 polyvinyl alcohol 10 flame retardant 5 Organic solvents 60 leveling agent 5 stabilizer 0.6

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com