A two-dimensional laser spiral cleaning method

A two-dimensional laser and laser cleaning technology, applied in cleaning methods and appliances, laser welding equipment, chemical instruments and methods, etc., can solve the problems of low cleaning efficiency, slow motor scanning speed, and uneven distribution of ablation area topography

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0034] In order to better understand the present invention, the content of the present invention is further illustrated below in conjunction with the examples, but the content of the present invention is not limited to the following examples.

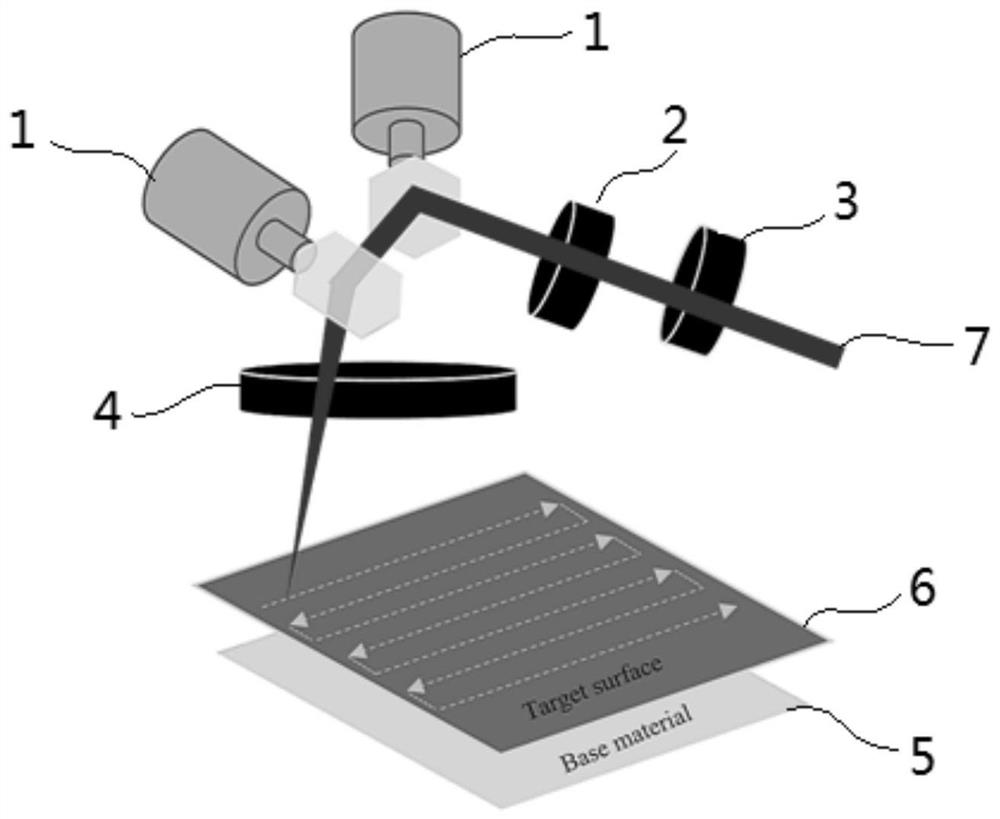

[0035] Such as figure 1 As shown, the fiber laser with a wavelength of 1064nm passes through the optical isolation system and the collimation system, and then enters the mirror on the motor shaft of the digital galvanometer. Surface stains on. figure 1 The target surface is shown for the existing row scan path.

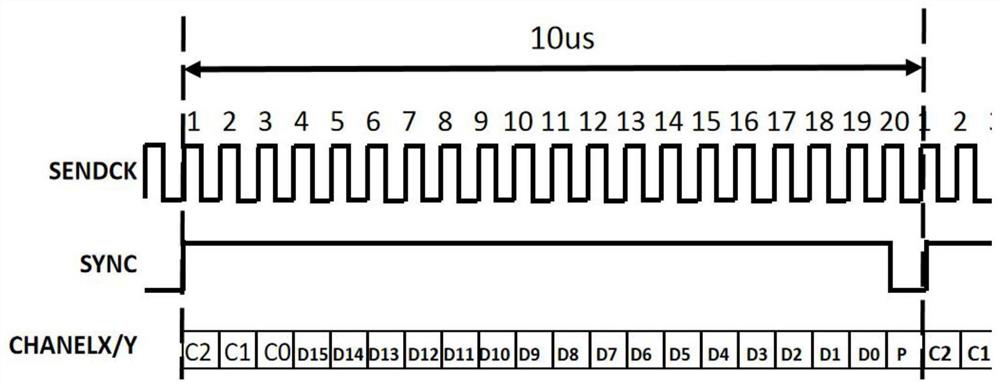

[0036] The cleaning system sends instructions representing the deflection angle of the motor to the digital galvanometer motor interface through the XY2-100 protocol to control the rotation of the motor. Such as figure 2 As shown, the protocol stipulates that the command data length is 20 bits, and the structure is 3 control bits, 16 data bits, 1 even parity bit, and the 16-bit data bit linearly corresponds to the absolute ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com