High-torque servo tensioner

A tensioner and high-torque technology, applied in the direction of conveying filamentous materials, thin material handling, transportation and packaging, etc., can solve problems such as breaking, inconvenient switching, decreased tension stability and buffer sensitivity, etc., to achieve accurate measurement, Intuitive tension, high flexibility and scientific results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

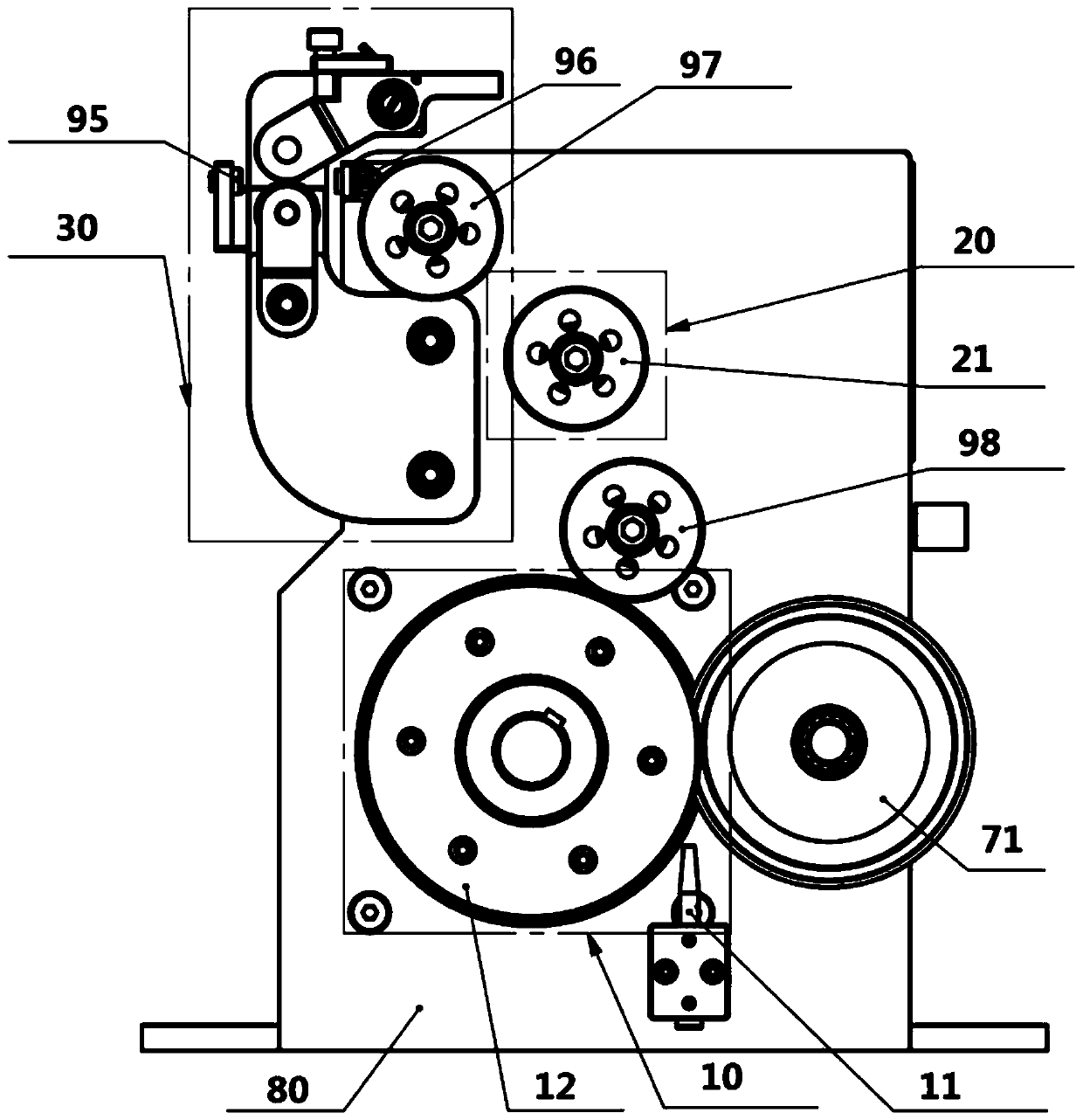

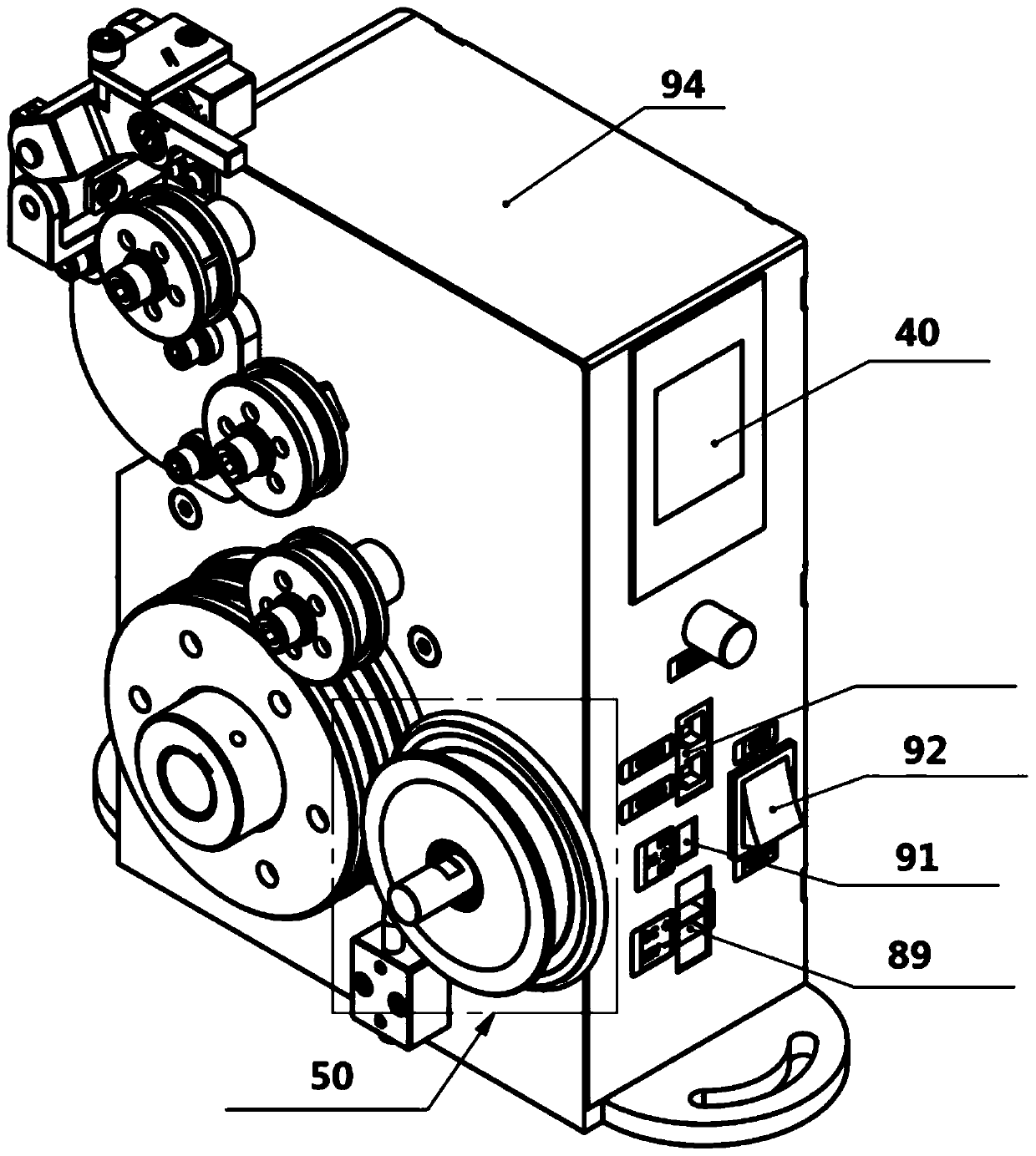

[0044] Embodiment 1, with reference to Figure 1-Figure 15 .

[0045] This embodiment provides a high-torque servo tensioner, refer to the attached figure 1 And attached figure 2 , comprising a mounting plate 80 and a casing 94 connected to the mounting plate 80, the mounting plate 80 is provided with a wire feeding structure 10, a measuring structure 20, and a shock absorbing structure 30, and the casing 94 is provided with a display device 40. The wire feeding structure 10 can perform active wire feeding, the measuring structure 20 can be used to measure the tension of the wire in real time, the shock absorbing structure 30 can be used to reduce the vibration at the wire outlet position, and the display device 40 can be used to real-time Display the working status of the tensioner (online / offline), display the tension upper limit set by the tensioner and display the current real-time tension of the tensioner.

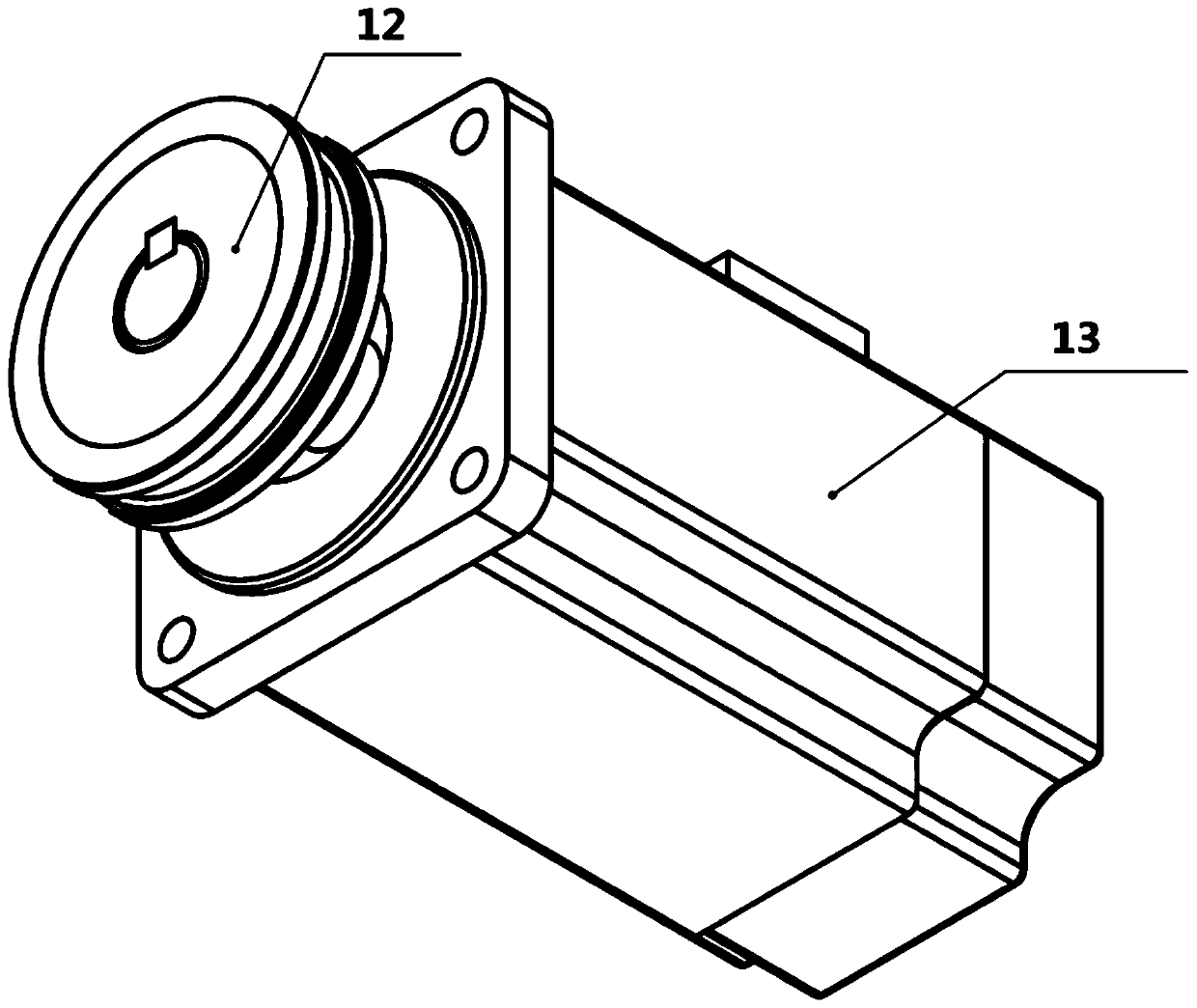

[0046] The wire feeding structure 10 includes a wire guide n...

Embodiment 2

[0061] Embodiment 2, with reference to Figure 16-Figure 20 .

[0062] In this embodiment, the arrangement positions of the second anti-jumper structure 98, the first anti-jumper structure 21, and the third anti-jumper structure 97 are different from those in Embodiment 1, The second anti-jumper structure 98 is located directly above the first anti-jumper structure 21, and the third anti-jumper structure 97 is located directly below the first anti-jumper structure 21 .

[0063] In this embodiment, the structure of the pressing wheel structure 50 is different from that in Embodiment 1. The pressing wheel structure 50 includes a connecting piece 100 fixed on the back of the mounting plate 80, and the connecting piece 100 is fixed with a first connecting rod 102 through connecting bolts 101, the first connecting rod 102 is arranged horizontally, and a pressure roller seat 103 is embedded in the mounting plate 80 at the upper side of the connecting piece 100, the A pinch wheel ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com