Virtual force feedback remote nano operation platform based on scanning electron microscope and method for realizing virtual force sensing interacting

An electron microscope and operating platform technology, applied in the field of remote nano-operation, can solve the problems of lack of image information, poor flexibility, and low operating efficiency of nanoparticles or components, and achieve the effects of ensuring safety, improving success rate, and enhancing perception ability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

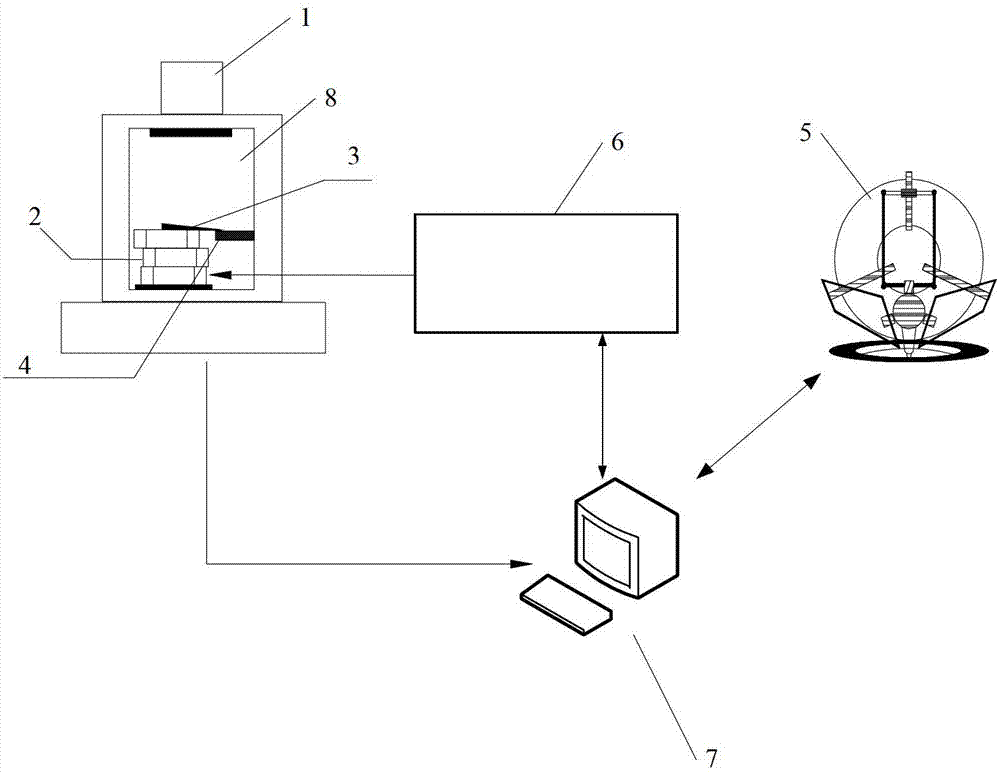

[0042] Specific implementation mode one: the following combination figure 1 Describe this embodiment, a scanning electron microscope-based virtual force feedback remote operation platform described in this embodiment, which includes a scanning electron microscope 1, a nanopositioner 2, an operation probe 3, a sample stage 4, and a tactile master hand Omega.35, nanopositioning controller 6, host computer 7 and sample cavity 8,

[0043] The sample cavity 8 is provided with a nanopositioner 2, and the nanopositioner 2 is located at the bottom of the sample cavity 8;

[0044] The nanopositioner 2 is provided with an operation probe 3, and the end of the operation probe 3 is in contact with the table top of the sample table 4; the sample table 4 is fixedly installed on the inner side wall of the sample cavity 8; the sample table 4 for placing nanowires;

[0045] The scanning electron microscope 1 is fixedly installed in the center above the sample cavity 8, the lens of the scanni...

specific Embodiment approach 2

[0052] Specific implementation mode two: the following combination figure 1 This embodiment will be described. This embodiment is a further description of Embodiment 1. The nanopositioner 2 described in this embodiment is realized by using an Attocube.

specific Embodiment approach 3

[0053] Specific implementation mode three: the following combination figure 1 This embodiment is described. This embodiment is a further description of Embodiment 1. The nanopositioning controller 6 described in this embodiment is realized by using the ANC150.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com