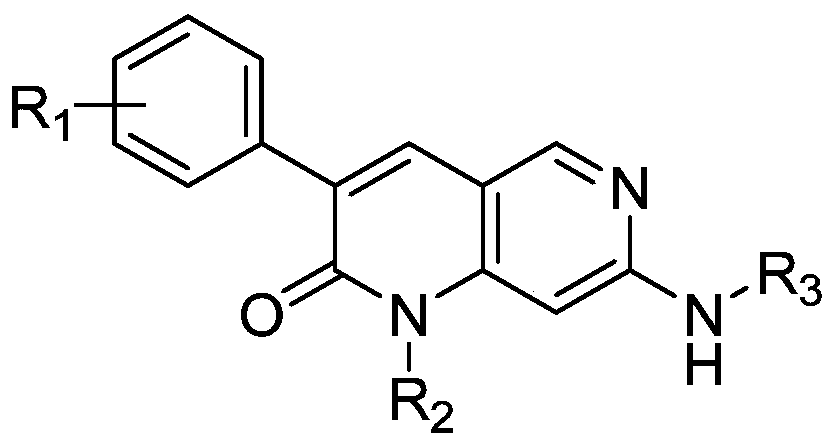

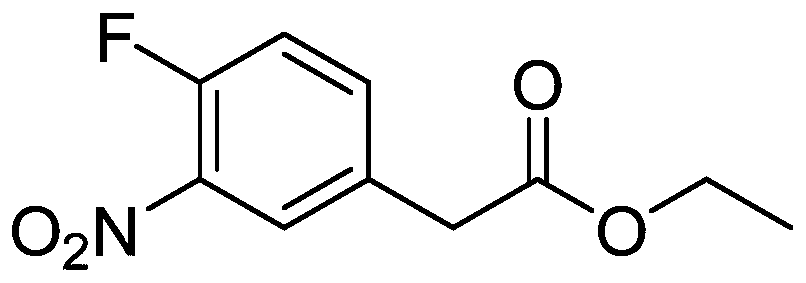

Preparation method of 3-nitro-4-fluorophenylacetate

A technology of fluorophenylacetate and fluorophenylacetate, which is applied in the field of preparation of 3-nitro-4-fluorophenylacetate, can solve the problems of low conversion rate of raw materials, poor spatial position selectivity, etc., and achieves safety High performance, control the heat release problem, and avoid the effect of rapid heat dissipation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

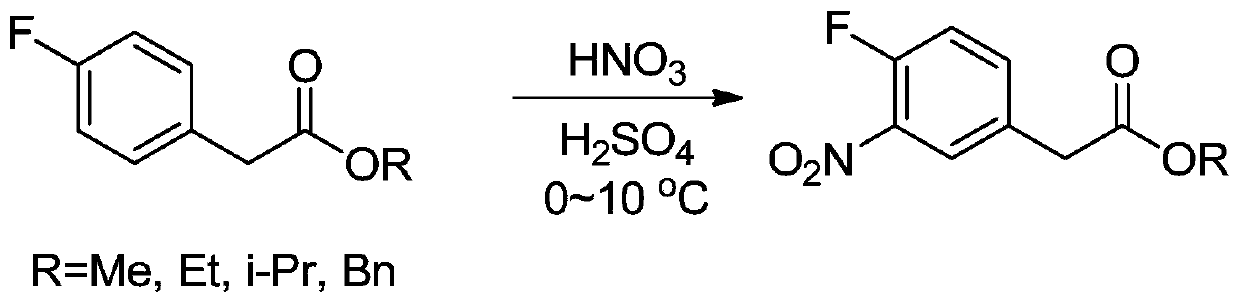

Method used

Image

Examples

Embodiment 1

[0034] (1) Preparation of raw materials: Take 200 g of ethyl 4-fluorophenylacetate and dissolve it in 280 mL of 98% sulfuric acid for later use. Take 79mL69% nitric acid for use.

[0035] (2) Pre-cooling: cool down the pre-cooling module and mixing module to 0-10°C. Use two constant flow pumps to pump the sulfuric acid solution and nitric acid solution of ethyl 4-fluorophenylacetate into two parallel pre-cooling modules for cooling to 0-10°C.

[0036] (3) Mixing: After the pre-cooling of the raw materials is completed, they enter the mixing module for mixing reaction. The flow rate of the mixed solution of 4-fluoroethyl phenylacetate and concentrated sulfuric acid is set to 15mL / min, and the flow rate of nitric acid is 2.63mL / min. The reaction stays in the mixing module 42s.

[0037] (4) Quenching and post-processing: the reaction liquid enters the quenching tank for quenching, and there are 500 mL of ethyl acetate and 500 mL of water in the quenching tank. The reaction sol...

Embodiment 2-9

[0039] The preparation method is the same as in Example 1, and the amount of ethyl 4-fluorophenylacetate is fixed at 200 g, the difference lies in the amount of raw materials and some process parameters. At the same time, in order to ensure that the mixed solution of 4-fluorophenylacetate and concentrated sulfuric acid and the nitric acid solution entering the mixing module of the microreactor can fully participate in the reaction, the flow rate is also changed as required. The products after the reaction are denoted as S2-S9.

Embodiment 10

[0042] (1) Preparation of raw materials: Take 185 g of methyl 4-fluorophenylacetate and dissolve it in 280 mL of 98% sulfuric acid for later use. Take 79mL69% nitric acid for use.

[0043] (2) Pre-cooling: cool down the pre-cooling module and mixing module to 0-10°C. Use two constant flow pumps to pump the sulfuric acid solution and nitric acid solution of methyl 4-fluorophenylacetate into two parallel pre-cooling modules for cooling to 0-10°C.

[0044] (3) Mixing: After the raw materials are pre-cooled, they enter the mixing module for mixing reaction. The flow rate of the mixed solution of methyl 4-fluorophenylacetate and concentrated sulfuric acid is set to 14.8mL / min, and the flow rate of nitric acid is 2.63mL / min. React in the mixing module Stay for 42s.

[0045] (4) Quenching and post-processing: the reaction liquid enters the quenching tank for quenching, and there are 500 mL of ethyl acetate and 500 mL of water in the quenching tank. The reaction solution was quench...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com