Constructional engineering quality control system based on combination of 3d laser sensing and BIM

A technology of construction engineering and control systems, applied in the direction of instruments, data processing applications, resources, etc., can solve the problems of high labor costs, a large number of testing personnel, rework, etc., and achieve the effect of avoiding engineering accidents

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

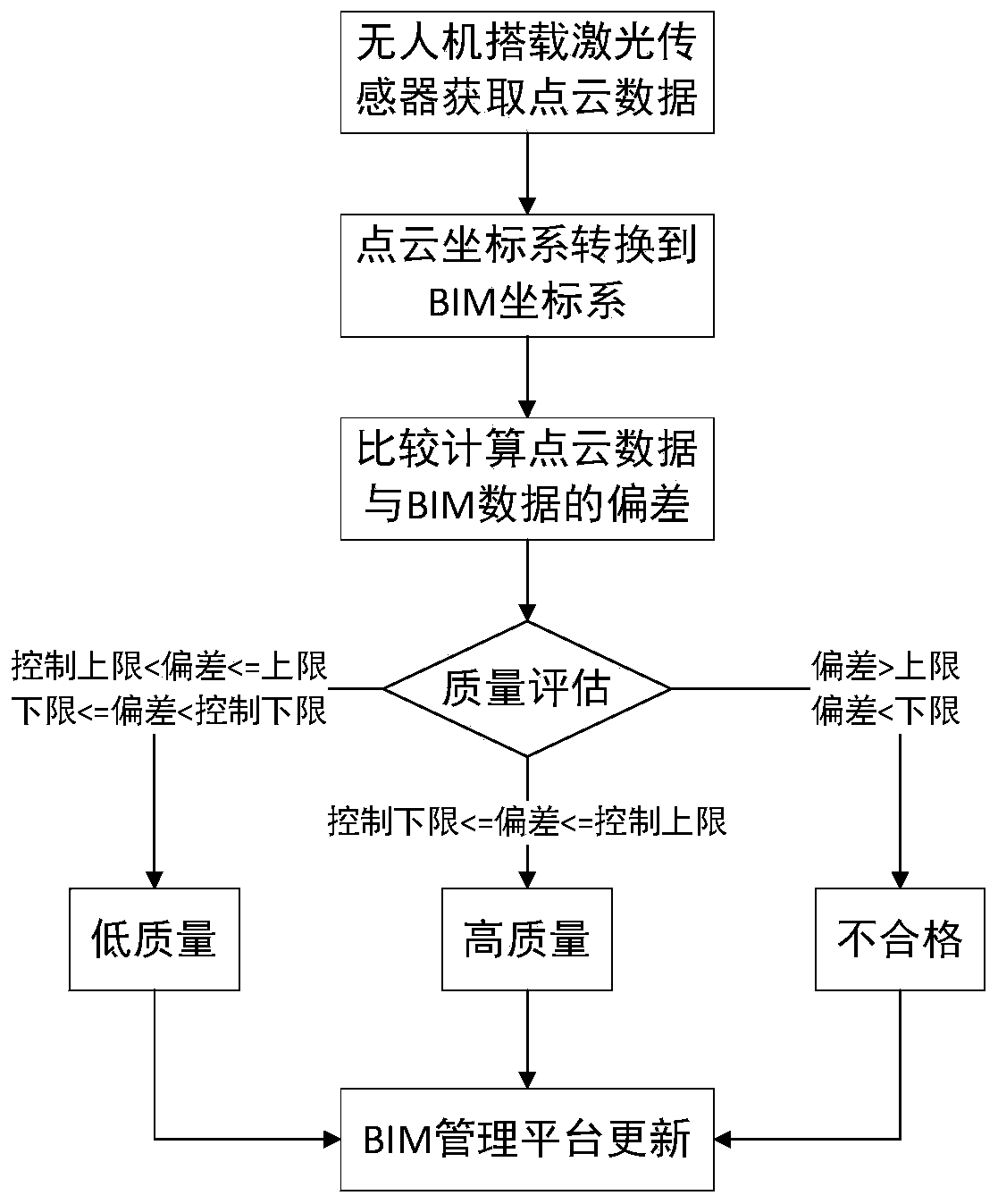

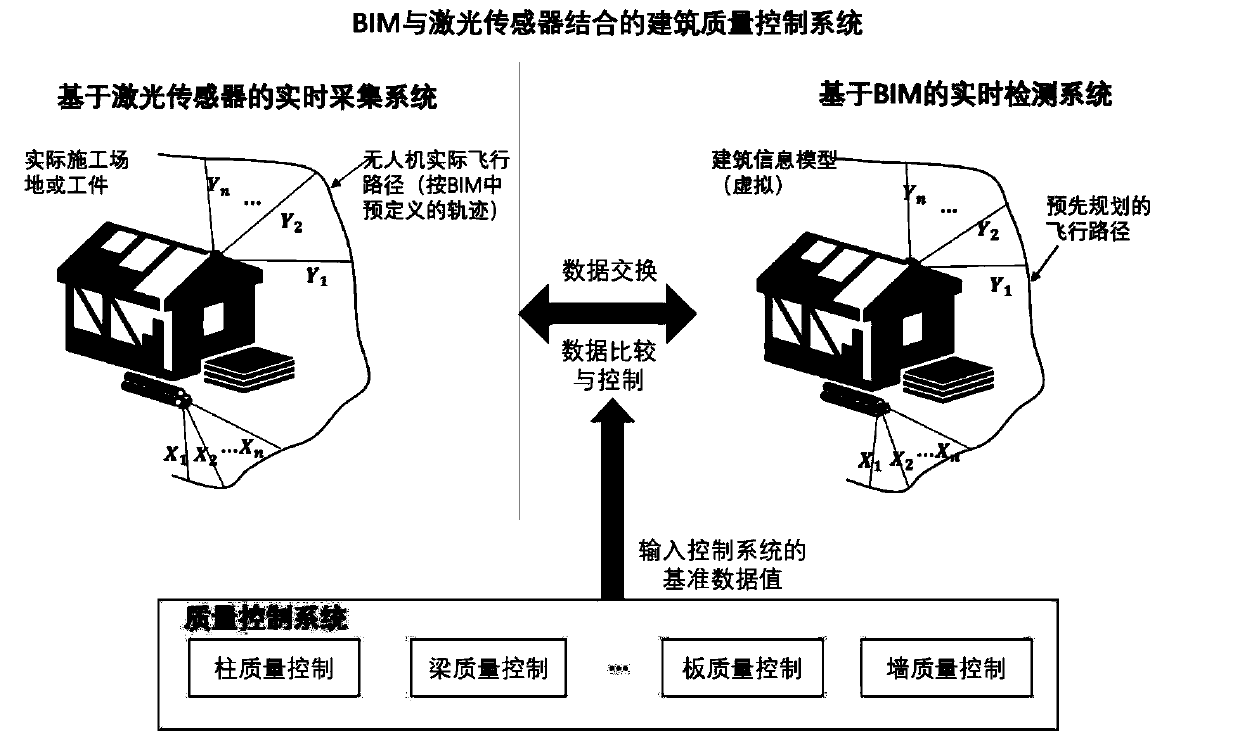

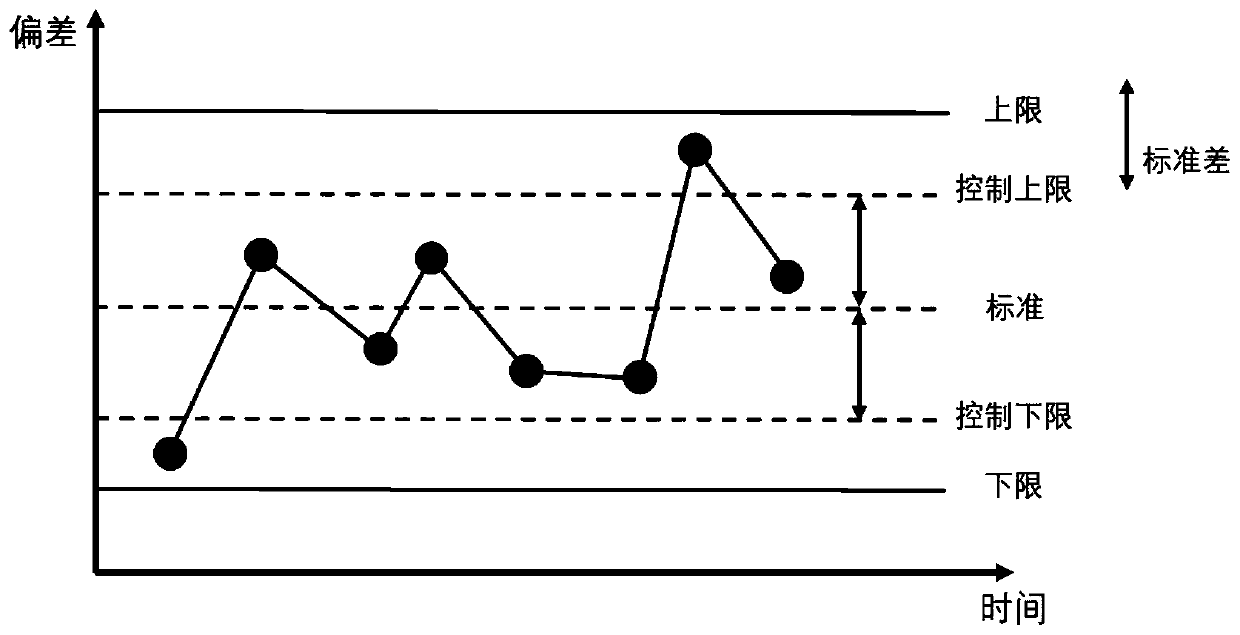

Method used

Image

Examples

Embodiment Construction

[0016] The present invention will be further described below in conjunction with the accompanying drawings.

[0017] BIM model (BIM technology)

[0018] BIM technology has been widely recognized by the industry around the world, helping to realize the integration of building information, from the design, construction, operation of the building to the end of the whole life cycle of the building, all kinds of information are always integrated in a 3D model information database, design Teams, construction units, facility operation departments and owners can work collaboratively based on BIM.

[0019] LiDAR

[0020] Laser detection and measurement technology uses GPS and IMU airborne laser scanning to measure a digital surface model represented by discrete points. The 3D laser ranging sensor can detect its surrounding environment almost without gaps, and can collect 3D point cloud data of the observed target surface either stationary or on a mobile platform. The combination of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com