Printing pancake baking machine

A steamed bun machine and printing technology, which is applied in food forming, food science, food coating, etc., can solve the problems of not being able to meet the individualization of the market, the surface viscosity of steamed buns is high, and the quality of steamed buns is single.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

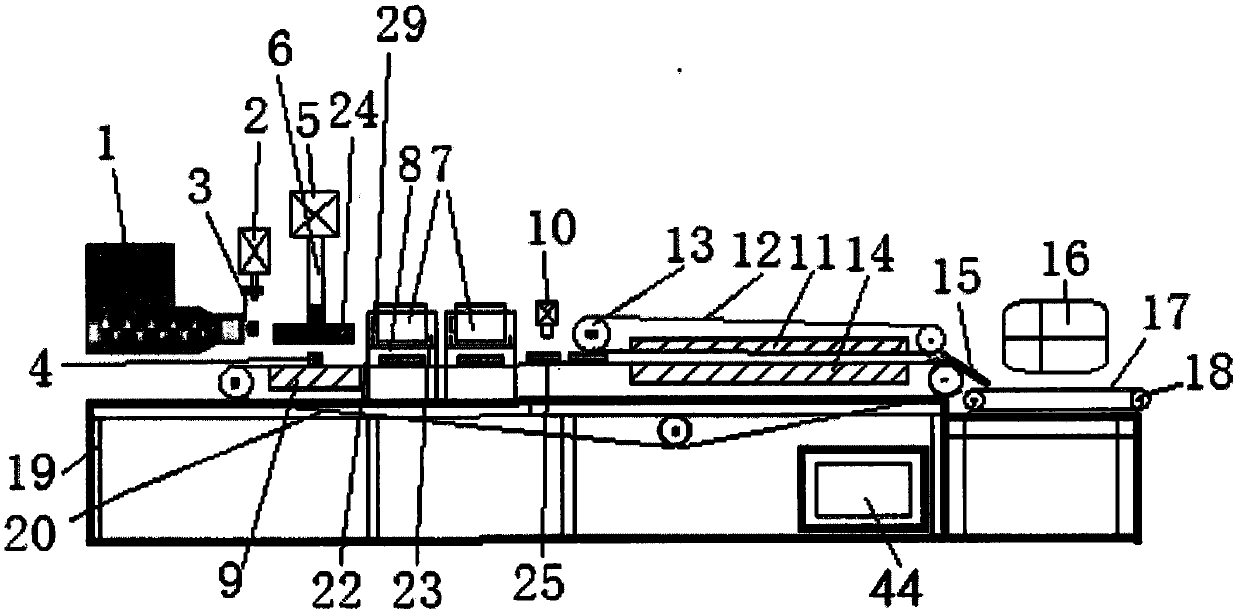

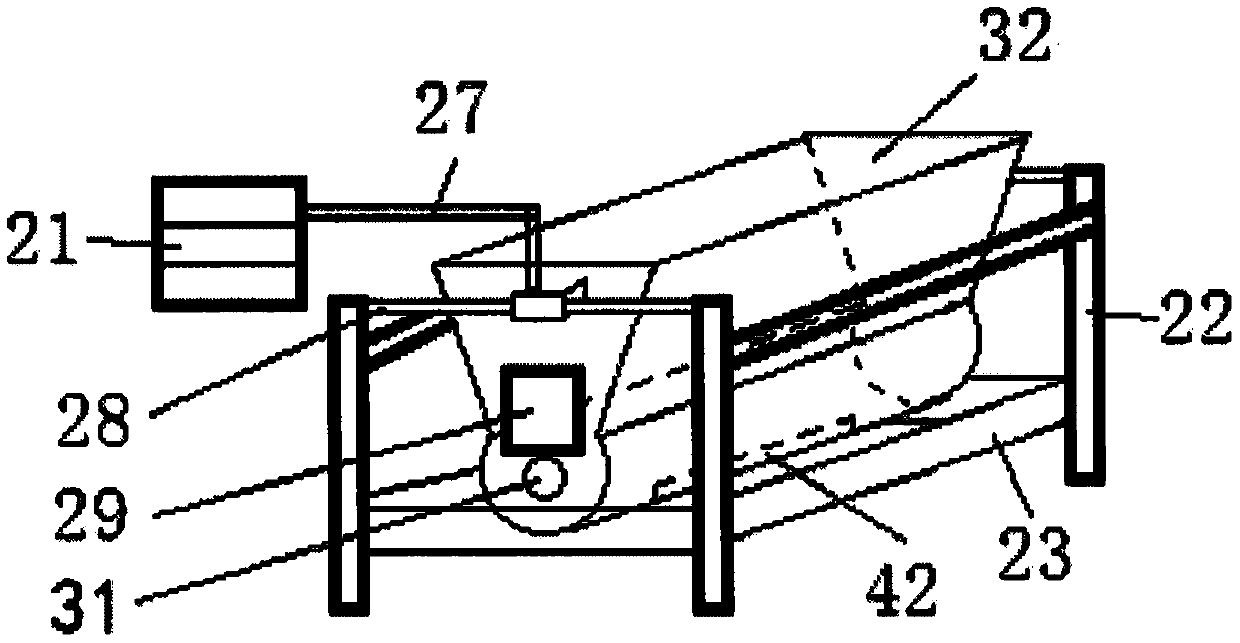

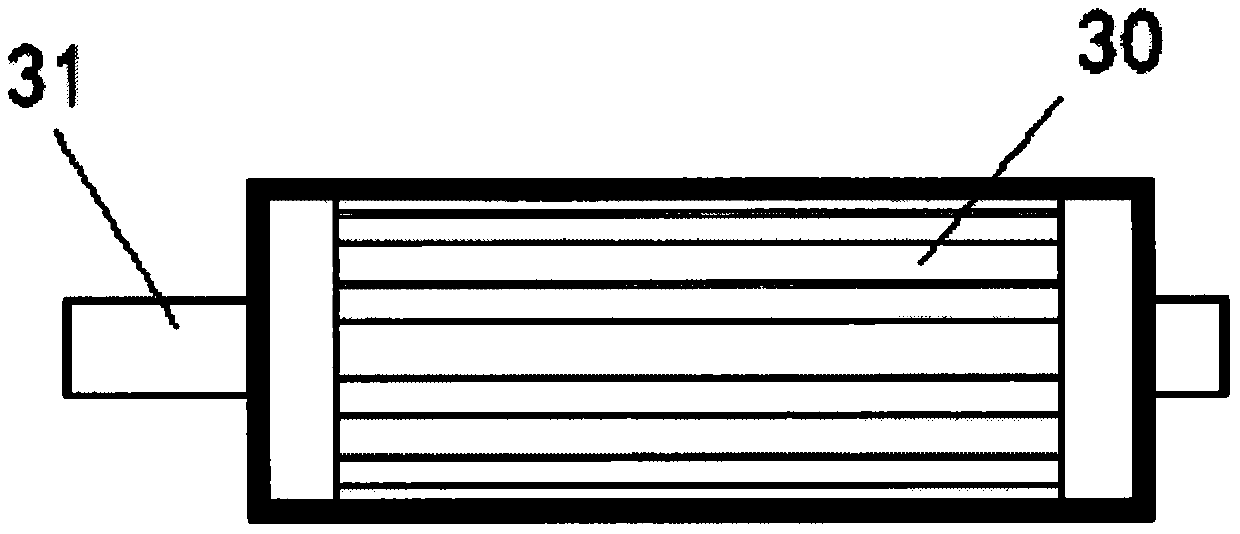

[0016] like figure 1 As shown, this is a schematic diagram of the printing steamed bun machine of the present invention. The upper platen 24 presses the dough base 4 into a dough sheet 25 under the control of the noodle pressing device controller 5. At this time, the dough sheet 25 is a semi-mature product, and the back sheet 25 is transported to the bottom of the printing device 7, in the hopper 32 Sesame leaks from discharge port 42 under the promotion of feeding gear 30, and leaks from the hollow hole 26 on the printing plate 8, at this moment leaks the design or the literal of sesame tissue design on dough sheet 25, then, The dough sheet 25 moves below the sprayer 10, and the anti-tack agent is sprayed onto the dough sheet from 10. The anti-tack agent used in the present embodiment is a methyl cellulose solution. Between 20, it is heated by secondary pressure (the upper heating plate 11, the lower heating plate 14, the upper conveyor belt 12, and the lower conveyor belt 2...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com