Device and method for inputting label paper of heating cigarette case

An input device and a technology of label paper, applied in transportation and packaging, a device for coating liquid on the surface, machining/deformation, etc., can solve the problems of separating, conveying, coding, gluing, and so on. Problems such as land occupation, large space occupation, unfavorable use and maintenance, etc., achieve the effect of wide versatility, small occupation area, and easy manufacture and maintenance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

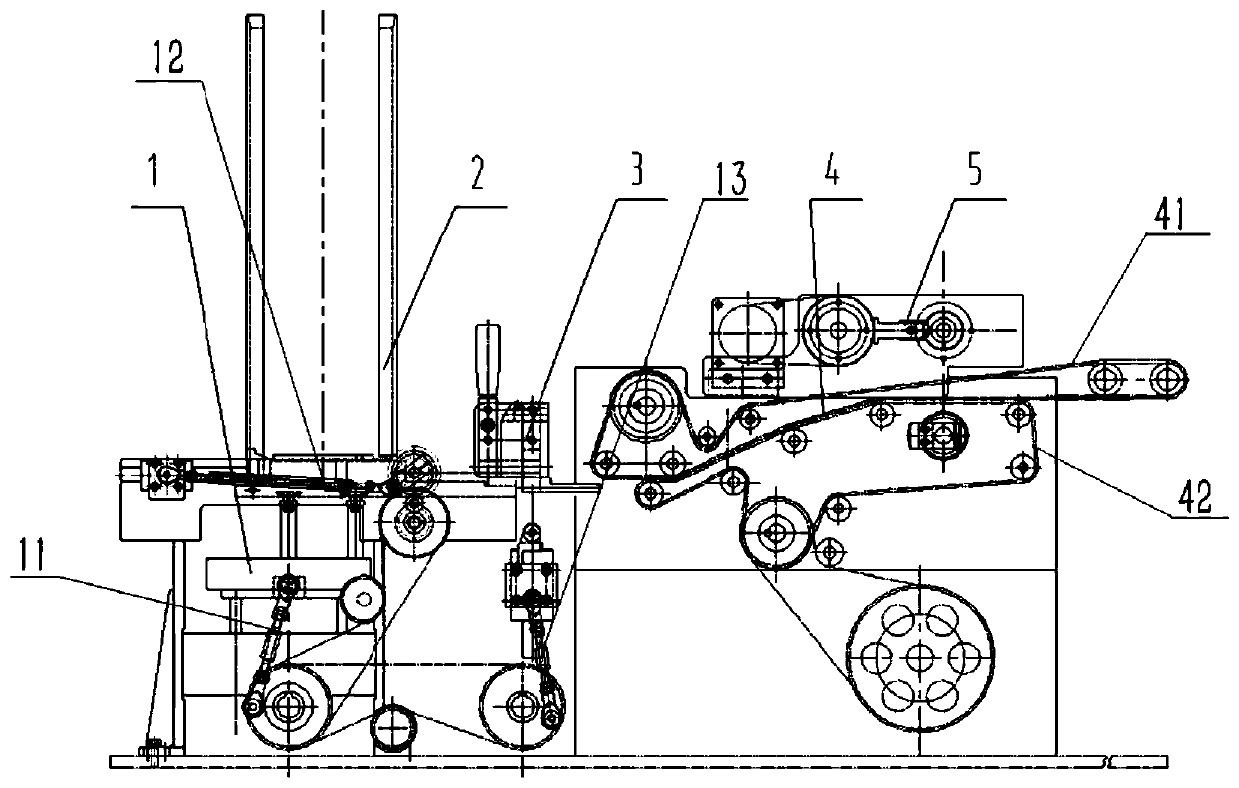

[0033] A heated cigarette box trademark paper input device, including a guide rail, a paper holder, a crank slider mechanism, a printing block, a conveyor belt, rollers, and glue-applied claws. The guide rail includes multiple guide rails. The paper holder cooperates with multiple guide rails and can Reciprocating motion, the crank slider mechanism includes multiple, the end of a crank slider mechanism in the multiple crank slider mechanisms can move between the conveyor belt and the roller along the guide rail, and a crank slider mechanism in the multiple crank slider mechanisms The end of the mechanism is connected to the printing block and drives the printing block to reciprocate. There are rollers on the side of the conveyor belt, and the rubber claws are offset against the rollers.

[0034] The guide rails include four guide rails arranged in a rectangle, and the four guide rails are used for placing label paper.

[0035] The guide rail is an L-shaped guide rail, and the ...

Embodiment 2

[0052] Embodiment 2 provides a method for inputting the trademark paper of a cigarette box, one of the slider crank mechanisms moves the trademark paper into the guide rail;

[0053] One of the slider crank mechanisms moves the label paper into the conveyor belt while one of the slider cranks uses a printing block to print on the label paper;

[0054] The label paper continues to move on the conveyor belt, and the glue coating claws brush the glue from the rollers on the inside of the label paper.

[0055] More specifically, this implementation uses the cigarette pack trademark paper input device disclosed in Example 1, and its specific operation steps are:

[0056] The first slider crank mechanism 11 moves the trademark paper from the trademark paper warehouse sub-device 2 into the horizontal guide rail, that is, below the paper holder;

[0057] The second slider crank mechanism 12 moves the label paper into the conveyor belt along the transverse guide rail, while the third ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com