A Piston Rod Surface Defect Detection System

A technology of defect detection and piston rod, which is applied in the direction of using liquid cleaning method, progressive dryer, sorting, etc., can solve the problems of visual fatigue, increased investment cost, inconsistent detection results, etc., and achieve high detection efficiency and low detection cost low effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

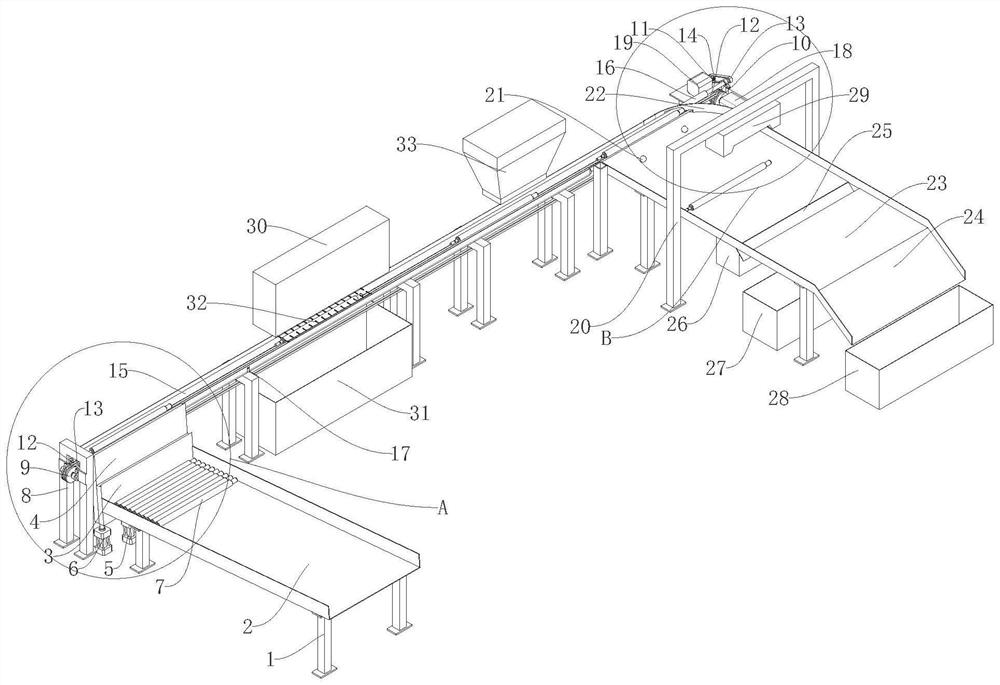

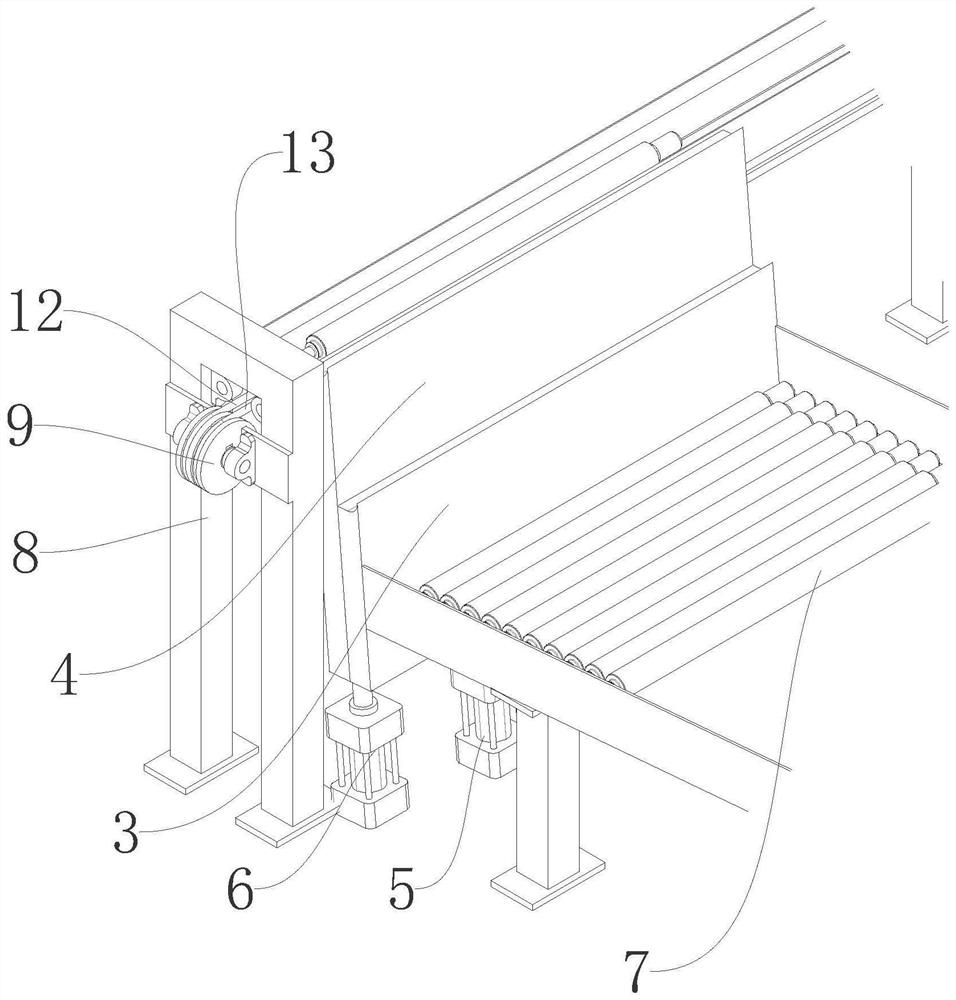

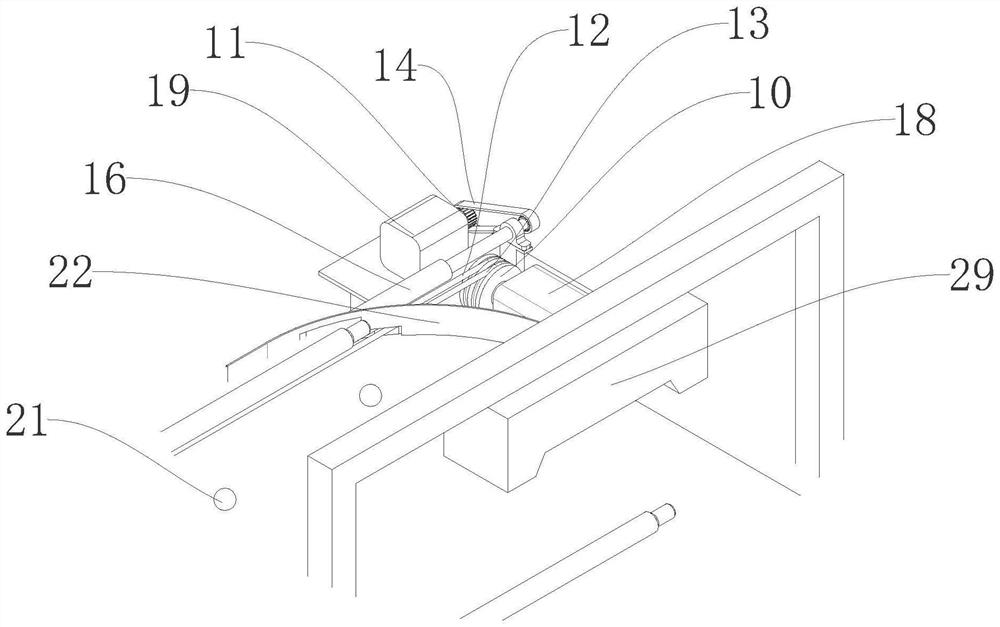

[0018] Embodiment: As shown in the figure, a piston rod surface defect detection system includes a feeding mechanism, a conveying mechanism, a cleaning mechanism, a drying mechanism, an image acquisition mechanism, a sorting mechanism and a control module; the feeding mechanism is used to stack A plurality of piston rods are separated individually and the piston rods are sent into the transmission mechanism in sequence from front to back. The transmission mechanism is used to send the piston rods into which the feeding mechanism is sent from left to right. To the sorting mechanism, the cleaning mechanism and the drying mechanism are respectively arranged above the conveying path of the conveying mechanism. When the piston rod on the conveying mechanism is conveyed from left to right, the piston rod first passes under the cleaning mechanism, and then passes through the drying mechanism. Below the mechanism, the cleaning mechanism is used to clean the pollutants on the surface of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com