Bending device for filter production

A bending device and filter technology, applied in the direction of feeding device, positioning device, storage device, etc., can solve the problems of many defective products, the device cannot control the bending position, etc., so as to improve the bending quality and reduce labor intensity and production costs, the effect of improving work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

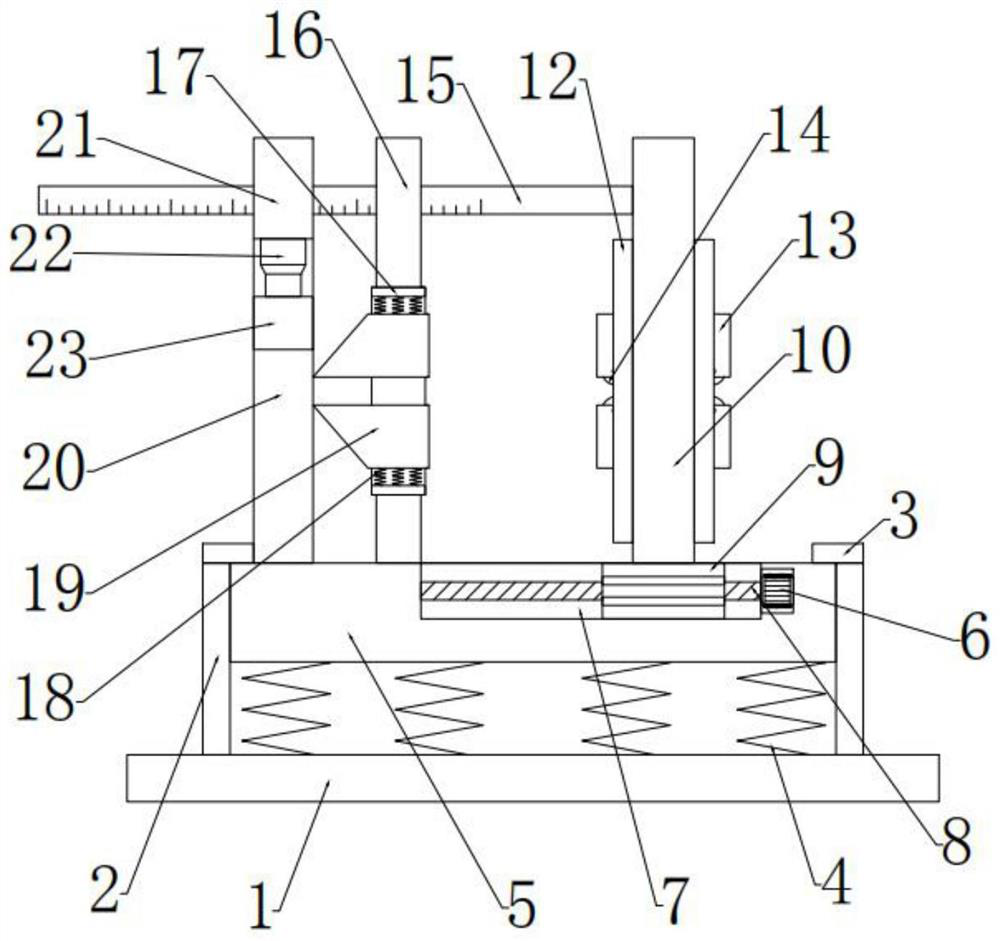

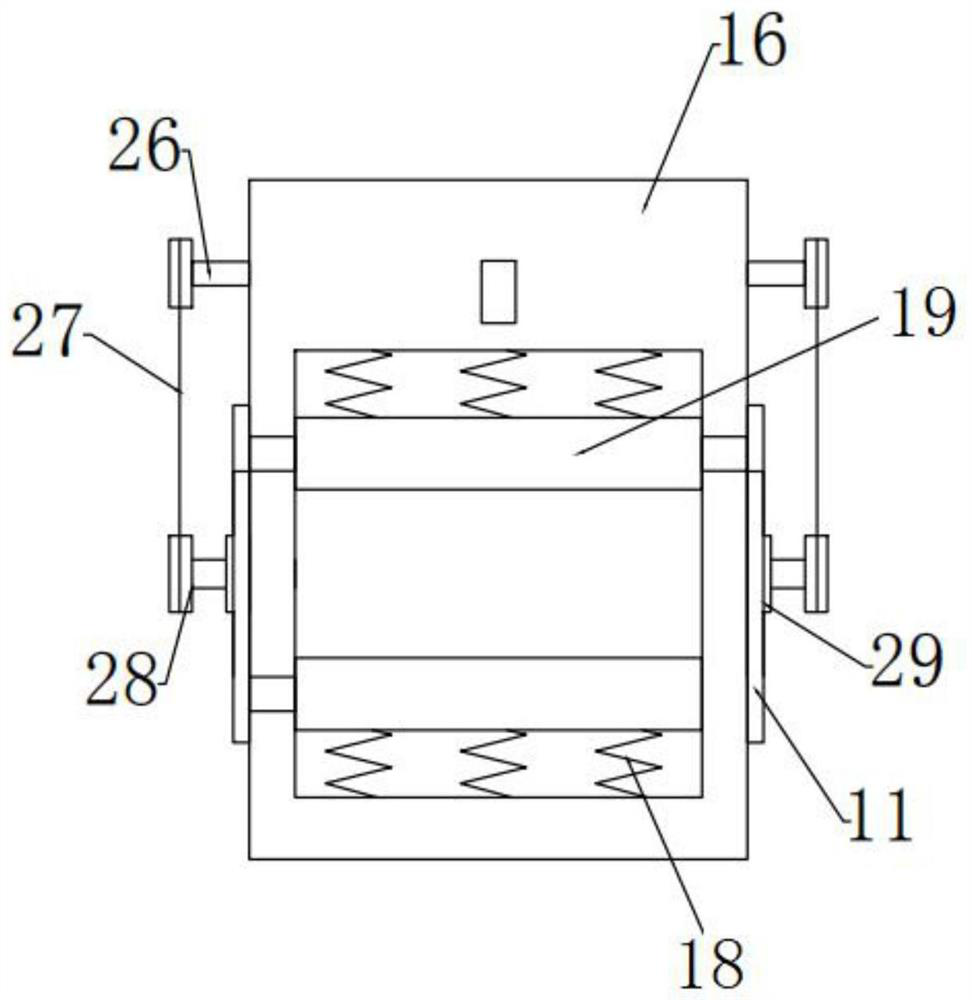

[0026] see Figure 1-4 , in an embodiment of the present invention, a bending device for filter production includes a base 1, a movable plate 5 is arranged on the upper side of the base 1, a shock absorbing mechanism is arranged between the movable plate 5 and the base 1, and the The top of the movable plate 5 is provided with a chute 7, the sliding connection on the chute 7 is provided with a feeding mechanism, and the left side of the feeding mechanism is provided with a bending mechanism fixedly connected with the movable plate 5, and the bending mechanism is connected with the feeding mechanism. A reinforcing mechanism is arranged between the mechanisms.

Embodiment 2

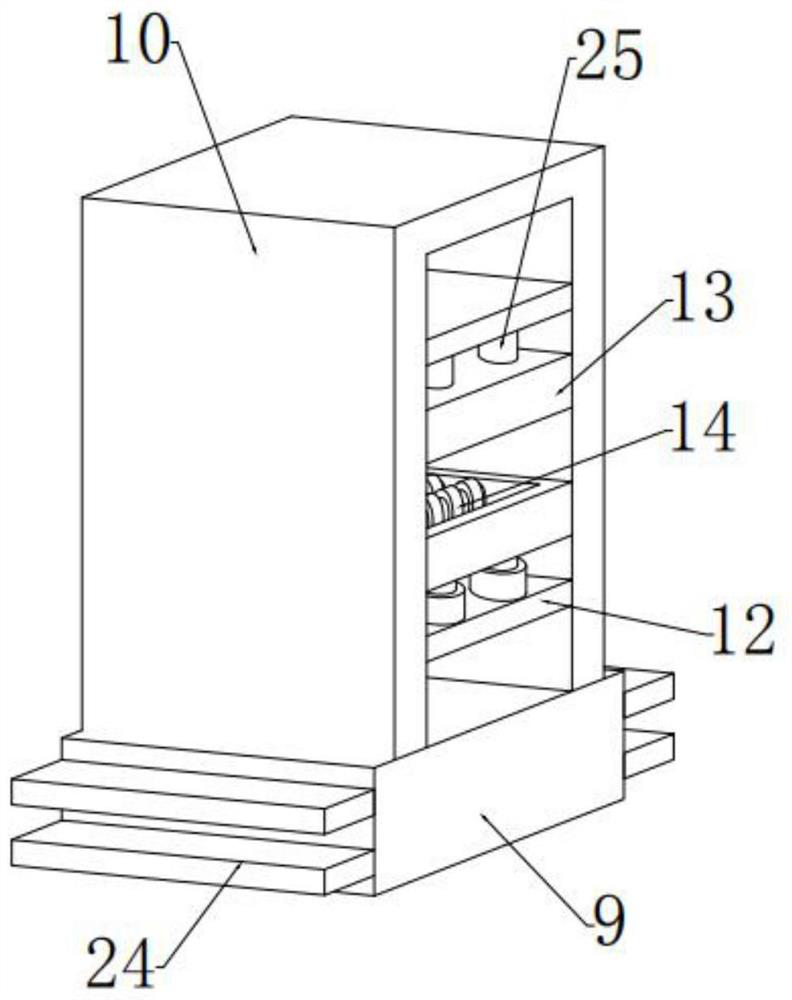

[0028] In this embodiment, the feeding mechanism includes a slider 9, the slider 9 is slidably connected to the inner side of the chute 7, the slider 9 is connected to the movable plate 5 through a driving mechanism, and the top of the slider 9 is fixedly connected A fixed block 10 is provided, the inner side of the fixed block 10 is fixedly connected with a fixed frame 12, and the upper and lower ends of the inner side of the fixed frame 12 are fixedly connected with a second telescopic rod 25, and the other end of the second telescopic rod 25 is connected to the The pressing plate 13 is connected, and the inner side of the pressing plate 13 is rotationally connected with several electric rollers 14, and the left side of the fixed block 10 is fixedly connected with a scale 15. By setting the feeding mechanism, the transportation of raw materials can be realized, which improves the work efficiency and reduces The labor intensity and production cost are reduced, and the raw mate...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com