Full-automatic pipe expanding machine and pipe expanding method

A flaring machine, fully automatic technology, applied in the direction of metal processing equipment, feeding devices, manufacturing tools, etc., can solve the problems of low production efficiency, low degree of automation, complex design, etc., and achieve the effect of improving production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

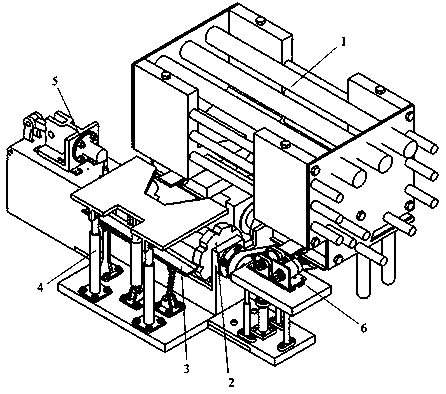

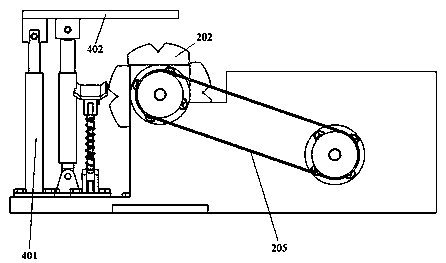

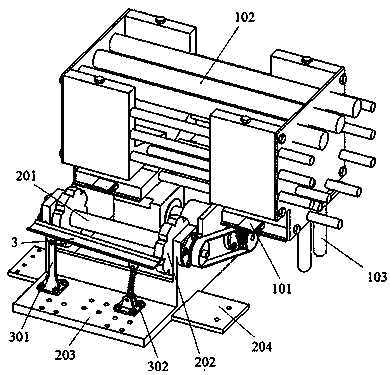

[0039] refer to figure 1 and image 3 As shown, a fully automatic pipe flaring machine includes an automatic loading and unloading device 1; it also includes a lifting and clamping mechanism 4 arranged on one side of the rotary table relative to the hopper 102; the lifting and clamping mechanism 4 includes a lifting column 401 and the cover plate 402; the lower end of the lifting column 401 is fixed on the frame floor of the rotary table 2, the upper end of the lifting column 401 is fixedly connected to the cover plate 402, and the inner side of the cover plate 402 extends directly above the loading station of the turntable 202; the rotary table 2 The two ends are respectively provided with a flaring mechanism 5 and an axial alignment mechanism 6.

[0040] Each mechanism of the automatic pipe flaring machine adopts a modular design, and a detachable connection is formed between each mechanism: one end of the hopper 102 is supported by the top plate of the frame of the rotary ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com