An automatic pneumatic hammer riveting device with controllable impact force

A pneumatic hammer and impact force technology, applied in the direction of fluid pressure actuating device, etc., can solve the problems of many impact times, difficult to precisely control, small impact force, etc., and achieve the effect of improving impact force, convenient carrying and stable performance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The present invention will be further described below in conjunction with drawings and embodiments.

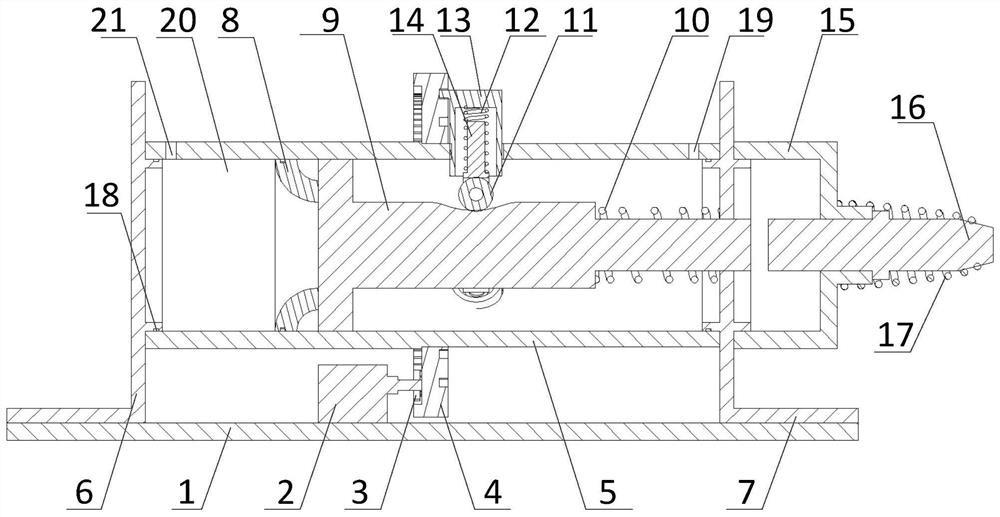

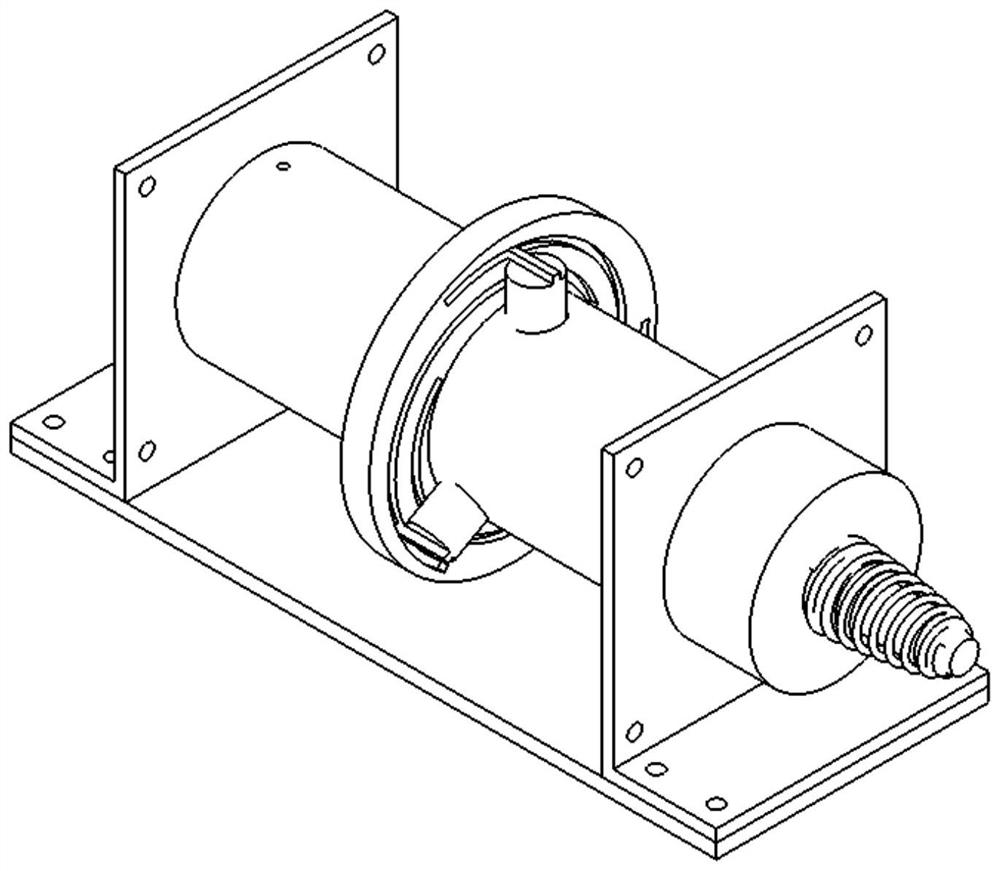

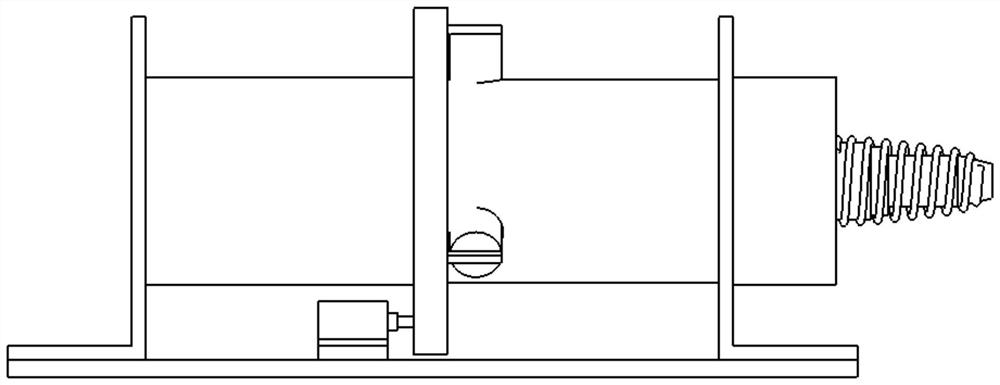

[0025] Such as figure 1 As shown, the specific implementation device includes a base plate 1, a servo motor 2, a gear 3, a gear helical groove plate 4, a main cylinder block 5, a rear end cover 6, a front end cover 7, an air storage ring 8, a cylinder main rod 9, Main rod back-moving spring 10, roller 11, sleeve compression spring assembly, cylinder secondary cylinder block 15, punching hammer 16 and punching hammer extension spring 17.

[0026] Such as figure 1 As shown, a front end cover 7 and a rear end cover 6 are respectively fixed on the front and rear sides of the base plate 1, a cylinder main cylinder body 5 is fixedly installed between the front end cover 7 and the rear end cover 6, and a cylinder is fixedly installed on the front end surface of the front end cover 7. Secondary cylinder block 15, cylinder sub-cylinder block 15 and cylinder main cylinder block...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com