Metal plate cutting machine for automobile production

A cutting machine, sheet metal technology, applied in the direction of shearing machine equipment, shearing device, metal processing equipment, etc., can solve the problems of sheet metal dislocation, large sheet metal damage, etc., to improve friction, improve firmness, and improve fixing. the effect of

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

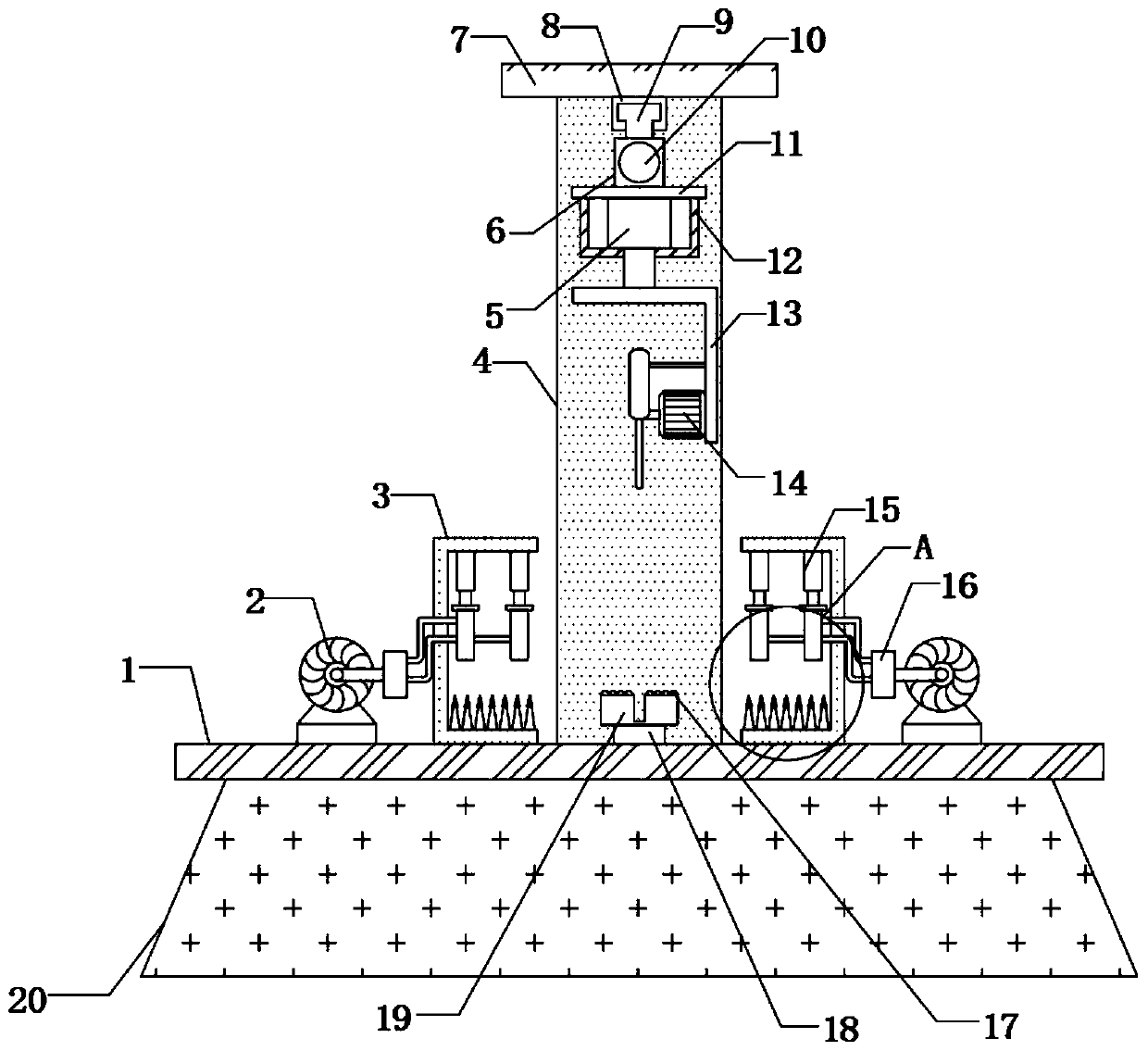

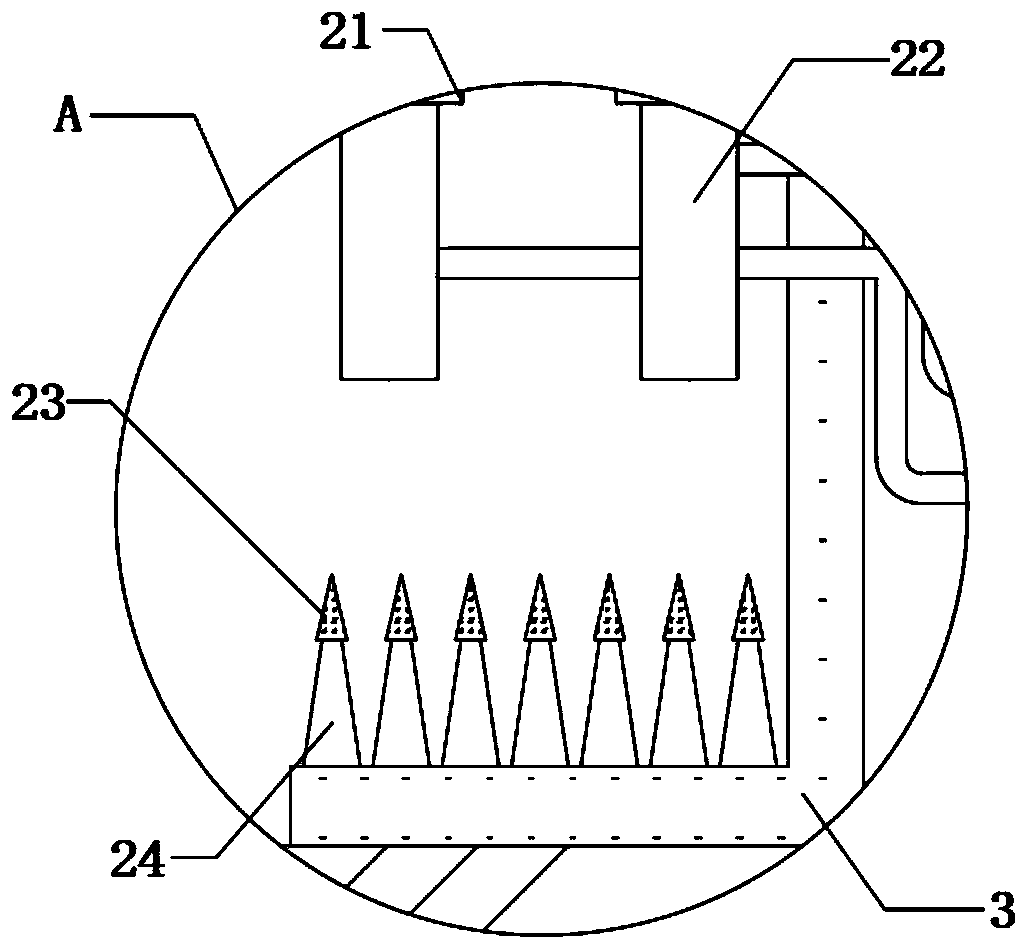

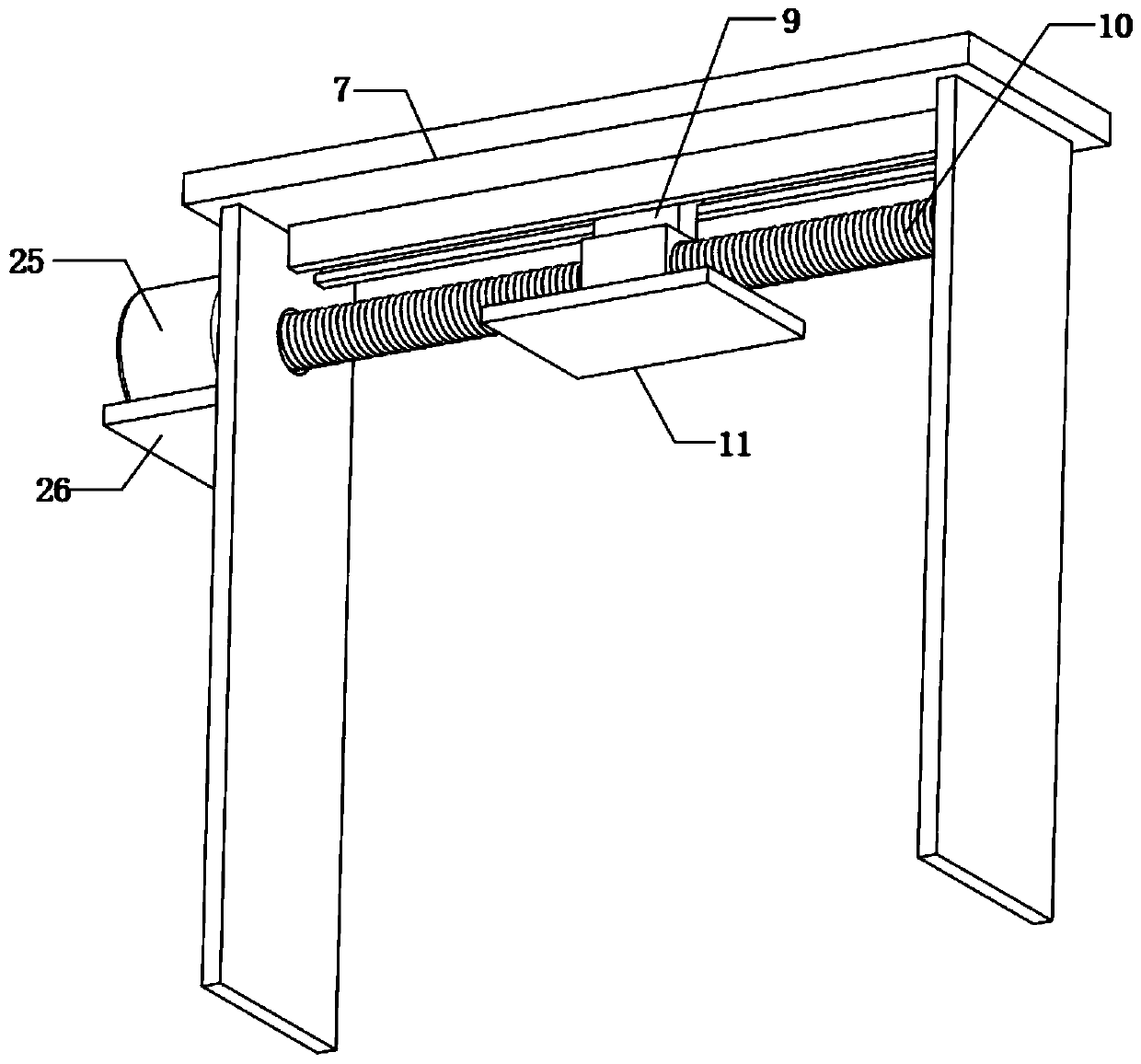

[0029] refer to Figure 1-5 , a sheet metal cutting machine for vehicle production, including a workbench 1, the top outer wall of the workbench 1 is fixed with two fixing frames 3 by screws, and the top inner walls of the two fixing frames 3 are fixed with four hydraulic rods by screws 15. The bottom outer walls of the two hydraulic rods 15 on the same horizontal line are fixed with the same adjustment plate 21 by screws, and the bottom outer walls of the adjustment plates 21 are equidistantly connected with fixed rods 22, and the fixed rods 22 on different adjustment plates 21 Arranged in a misplaced position, the outer wall of the top of the workbench 1 close to the fixed frame 3 is fixed with a suction pump 2 by screws, and the suction ends of the two suction pumps 2 are connected to a flow divider 16 through a pipeline, and the inner walls of a plurality of fixed rods 22 are connected to each other. There is an air hole 27, and each fixed rod 22 is connected to the divert...

Embodiment 2

[0040] refer to figure 1 , figure 2 , Figure 4 , Figure 5 and Figure 6, a sheet metal cutting machine for vehicle production, including a workbench 1, the top outer wall of the workbench 1 is fixed with two fixing frames 3 by screws, and the top inner walls of the two fixing frames 3 are fixed with four hydraulic rods by screws 15. The bottom outer walls of the two hydraulic rods 15 on the same horizontal line are fixed with the same adjustment plate 21 by screws, and the bottom outer walls of the adjustment plates 21 are equidistantly connected with fixed rods 22, and the fixed rods 22 on different adjustment plates 21 Arranged in a misplaced position, the outer wall of the top of the workbench 1 close to the fixed frame 3 is fixed with a suction pump 2 by screws, and the suction ends of the two suction pumps 2 are connected to a flow divider 16 through a pipeline, and the inner walls of a plurality of fixed rods 22 are connected to each other. There is an air hole 27...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com