Combined drum chipper for cutting chunks, flakes or strips of wood

A combination type chipper technology, applied in wood processing equipment, manufacturing tools, etc., can solve the problem of excessive wood chips, and achieve the effects of avoiding slipping, improving work efficiency, avoiding slipping and large vibration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

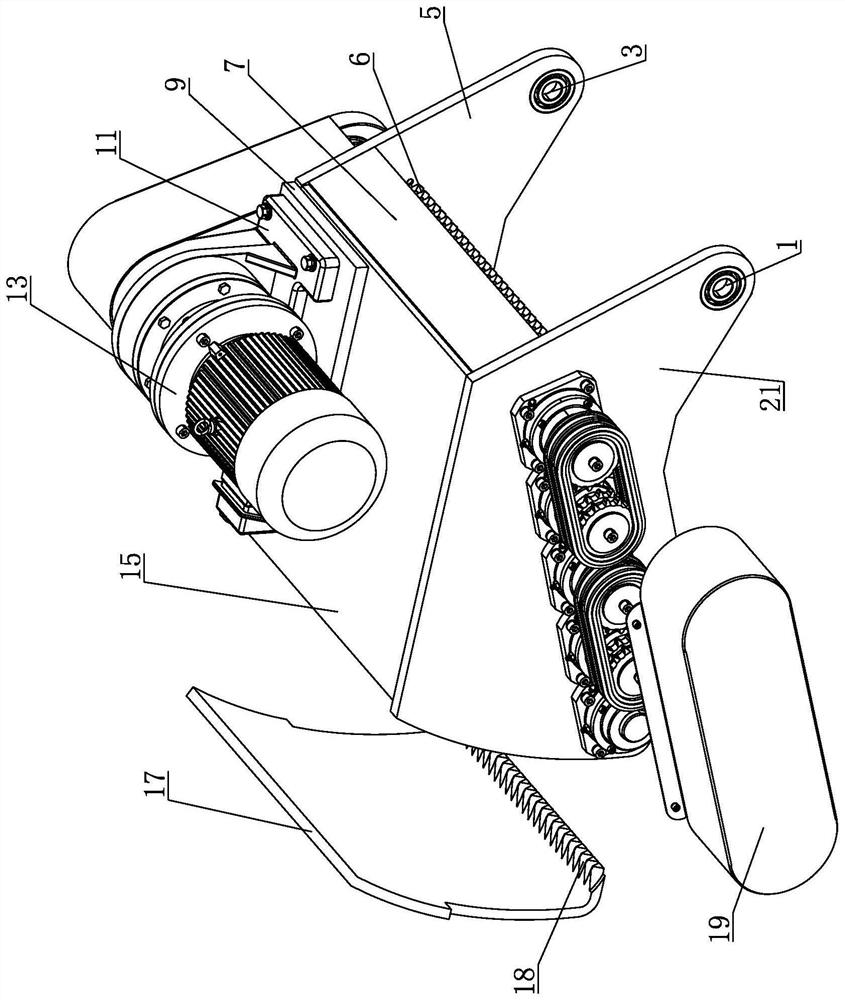

[0070] A combined drum chipper suitable for cutting thick blocks, thin slices or strips of wood, consisting of a body (53) and an upper collar (55) at the feeding port; the body (53) includes a frame and a frame mounted on the frame. The upper knife drum (39) and bottom knife, the lower collar (29) of the feeding port.

[0071] The upper flange of the feeding port is hinged with the frame.

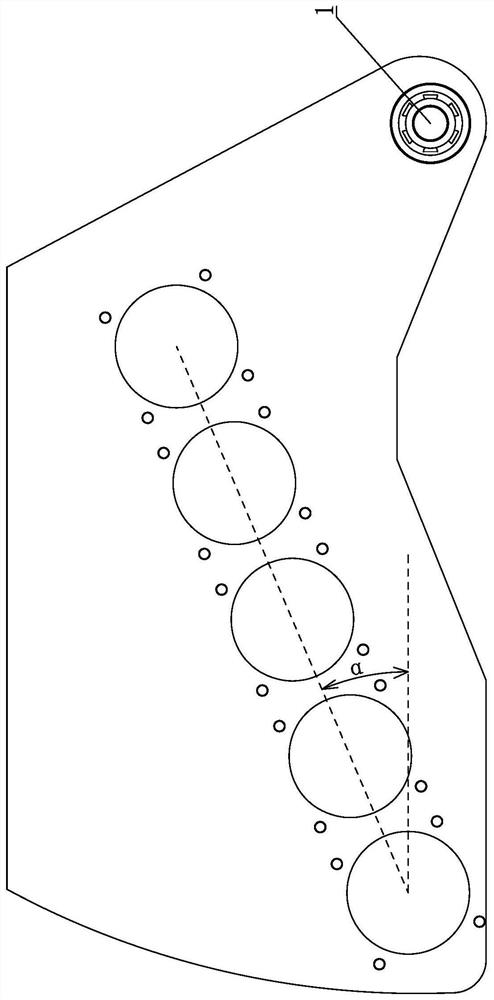

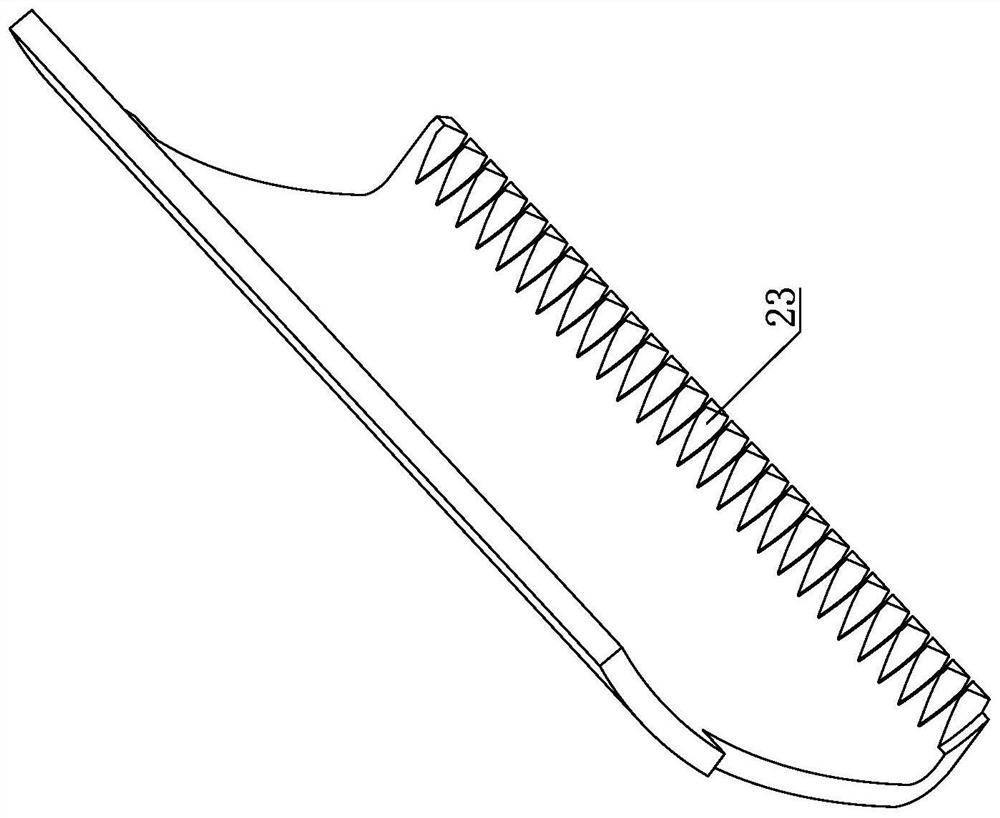

[0072] The upper collar of the feeding port includes the upper collar left side plate (21), the upper collar right side plate (5), the upper collar front cover (17), the upper collar rear cover (7), the upper collar upper cover (15 ), the upper flange toothed roller group (6); the two ends of the roller shaft of each toothed roller in the upper flange toothed roller group are respectively installed on the upper flange left side plate and the upper flange right side plate through bearing seats and bearings; Between the toothed roller and the toothed roller, the sprocket is installed at the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com