Molding device for producing degradable biologic film bags

A technology of biofilm and supporting frame, which is applied in the field of molding devices for producing biodegradable biofilm bags, which can solve the problems of poor cooling effect and affecting the use of equipment, and achieve the effects of convenient use, convenient movement, and improved work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

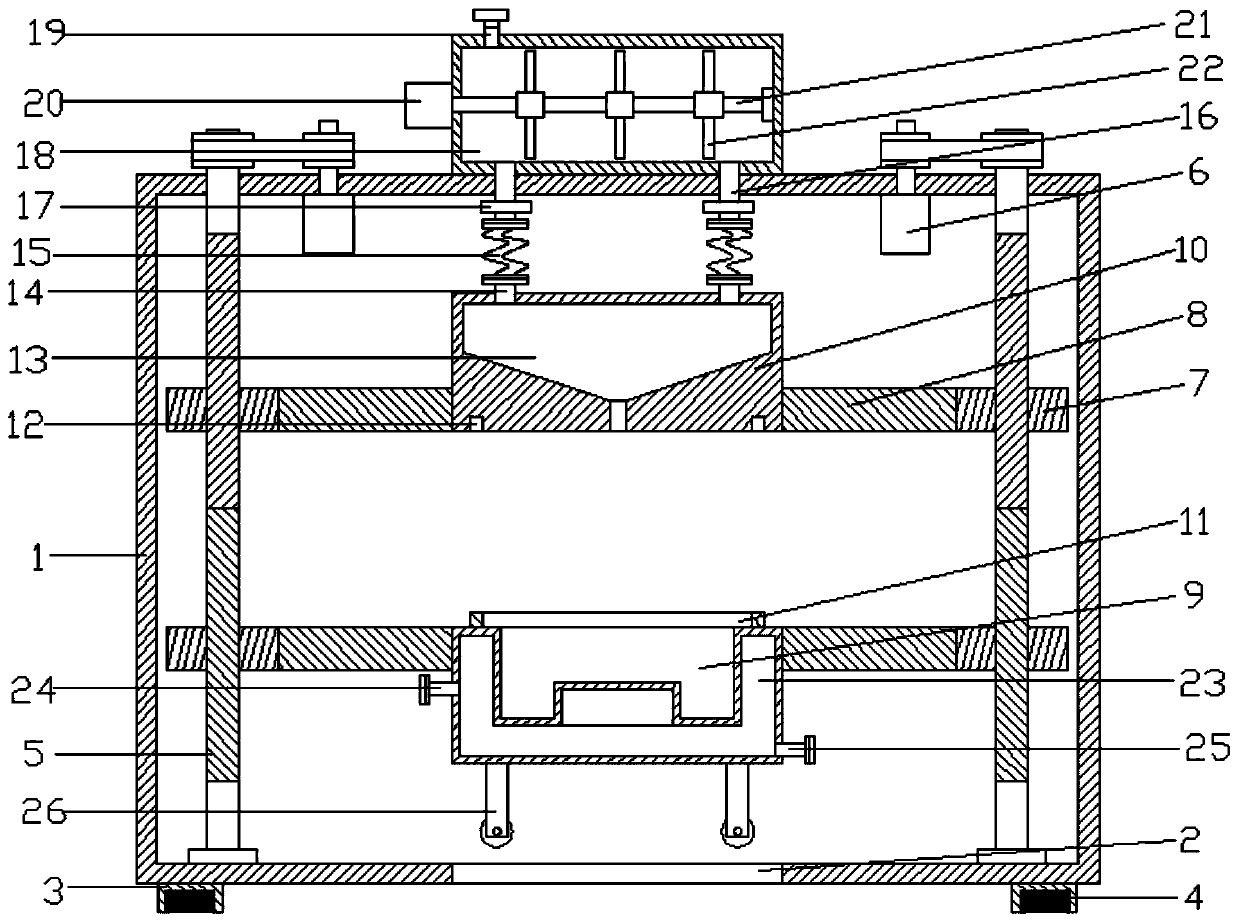

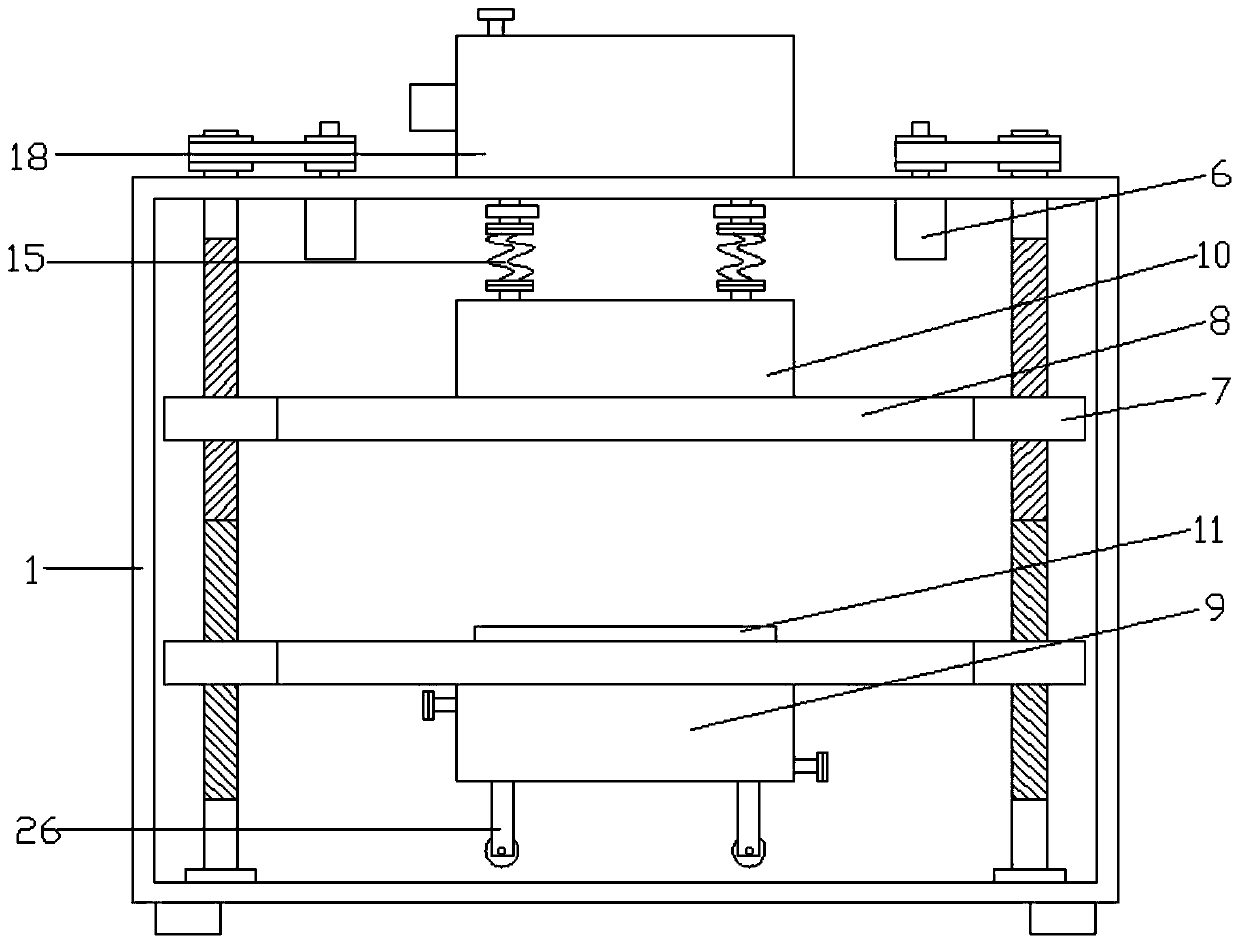

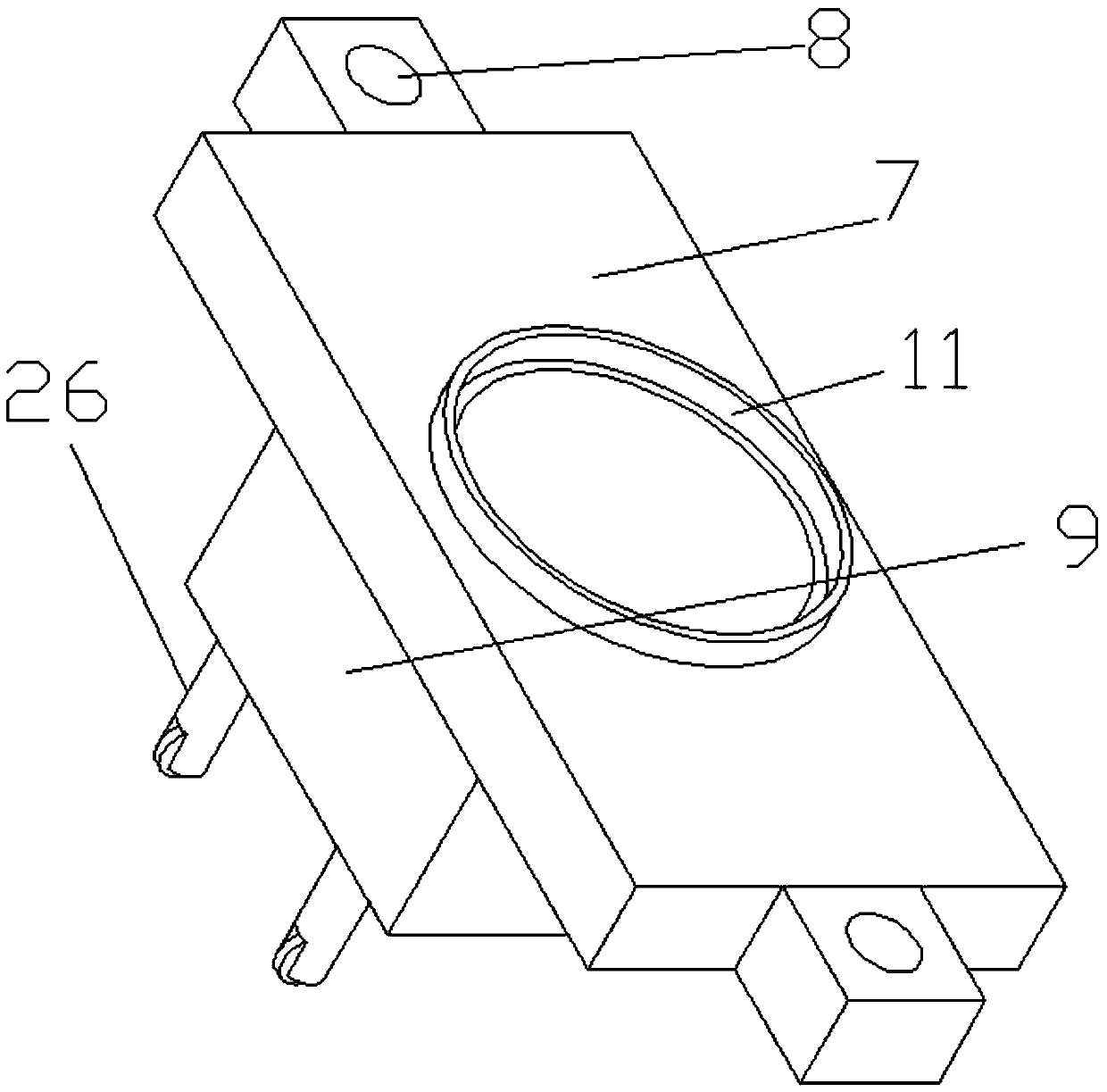

[0025] refer to Figure 1~3 , in an embodiment of the present invention, a molding device for producing degradable biofilm bags includes a support frame 1, the bottom of the support frame 1 is provided with an opening 2, and the left and right ends of the support frame 1 are provided with two-way The threaded rod 5, the bottom of the two-way threaded rod 5 is connected with the support frame 1 through the bearing seat, the two-way threaded rod 5 on the upper side of the support frame 1 is connected with the synchronous motor 6 through the belt, and the synchronous motor 6 is installed on the top of the support frame 1 on the left and right sides Both ends, the upper and lower ends of the two-way threaded rod 5 are provided with sliders 7, between the sliders 7 at the upper end and the sliders 7 at the lower end, connecting plates 8 are arranged, and the connecting plates 8 are located inside the support frame 1 up and down Both ends, the middle part of the connecting plate 8 a...

Embodiment 2

[0029] The difference from Embodiment 1 is that support blocks 3 are installed at the four corners of the support frame 1 outside the opening 2, and the lower end of the support block 3 is inlaid with friction pads 4, which can increase the friction between the equipment and the ground, so as to ensure the stability of the equipment , so as to facilitate the use of equipment.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com