Warp-weft knitted double-sided fabric, preparation method and processing system thereof

A technology of double-sided fabrics and weft-knitted fabrics, applied in chemical instruments and methods, lamination auxiliary operations, lamination, etc., can solve the problems of poor fabric flexibility, harmful human skin, and environmental pollution, and achieve easy transformation, Strong three-dimensional effect and strong decorative effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

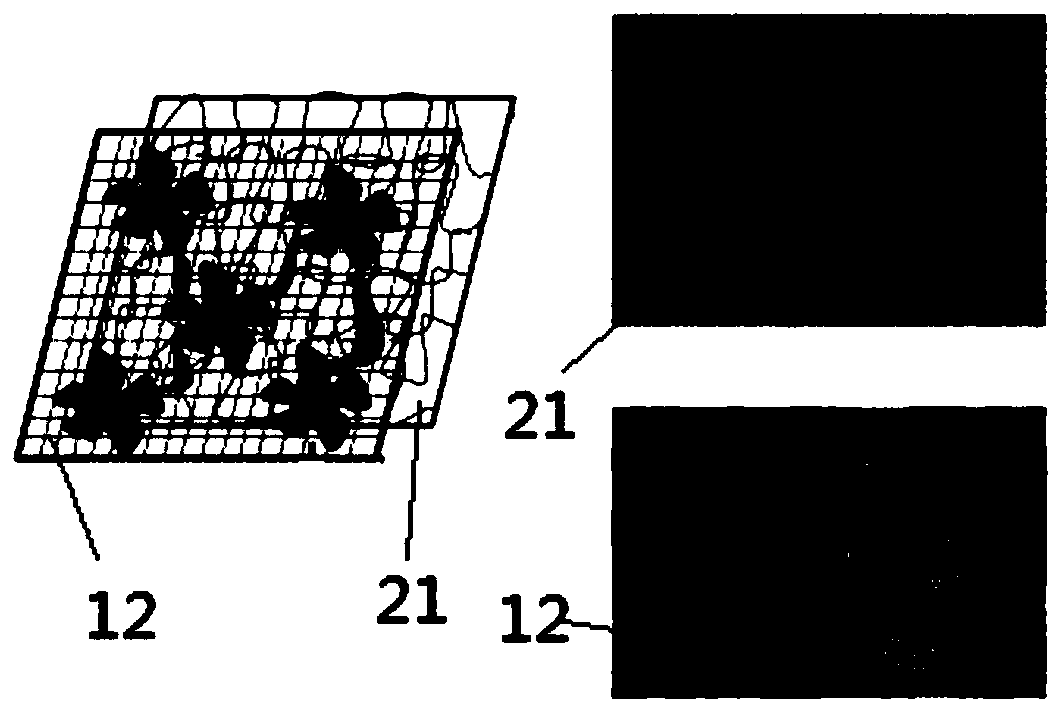

[0033] This embodiment provides a warp-weft-knitted double-sided fabric. The weft-knitted fabric is used as the base fabric and the warp-knitted fabric is used as the cloth surface. The two are laminated up and down and compounded by needle punching to form a warp-weft-knitted composite double-sided fabric. The performance of the knitted warp-weft-knitted double-sided composite fabric combines the advantages of warp-knitted fabrics and weft-knitted fabrics. It has a stable structure and a soft feel. It can be used as various knitted clothing or home textiles. The weft-knitted fabric layer is close to the skin of the body, soft and skin-friendly , the warp knitted layer is used as the outer layer, which is beautiful and decorative; and the outer layer of the composite fabric has a fleece effect, which is warm and comfortable.

[0034] The weft-knitted fabric described in the above technical solution is a weft-knitted fabric or a double-sided fabric or a variable-knitted fabric w...

Embodiment 2

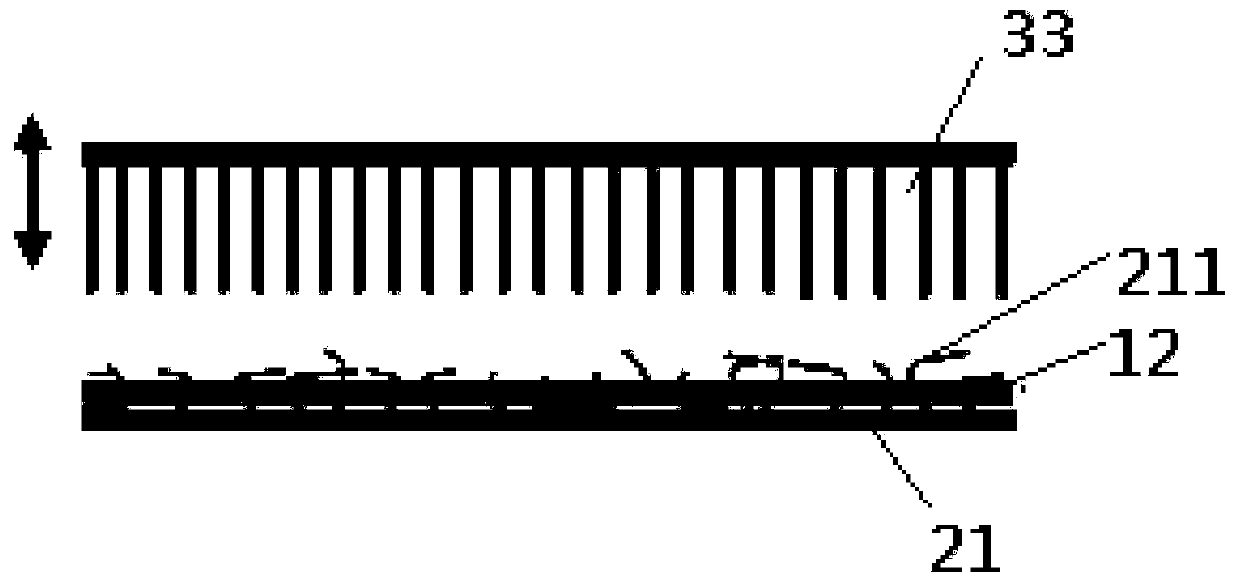

[0039] Such as figure 2 As shown, the present embodiment provides a kind of preparation method of warp and weft knitted double-sided fabric as above, it is characterized in that, comprises the steps:

[0040] Step 1, using the weft knitting machine and the warp knitting machine to weave the weft knitted fabric and the warp knitted fabric respectively according to the preset fabric structure;

[0041] Step 2, laying the weft knitted fabric obtained in step 1 on the needle bed of the acupuncture equipment, and then laying the warp knitted fabric obtained in step 1 on the upper end of the weft knitted fabric;

[0042] Step 3: The needling equipment drives the needles to combine the weft-knitted fabric and the warp-knitted fabric on the needle bed, wherein the needle density and the needling times of the needling equipment are determined according to the fabrics of the warp-knitted fabric and the weft-knitted fabric. The warp-knitted fabric and the weft-knitted fabric are direct...

Embodiment 3

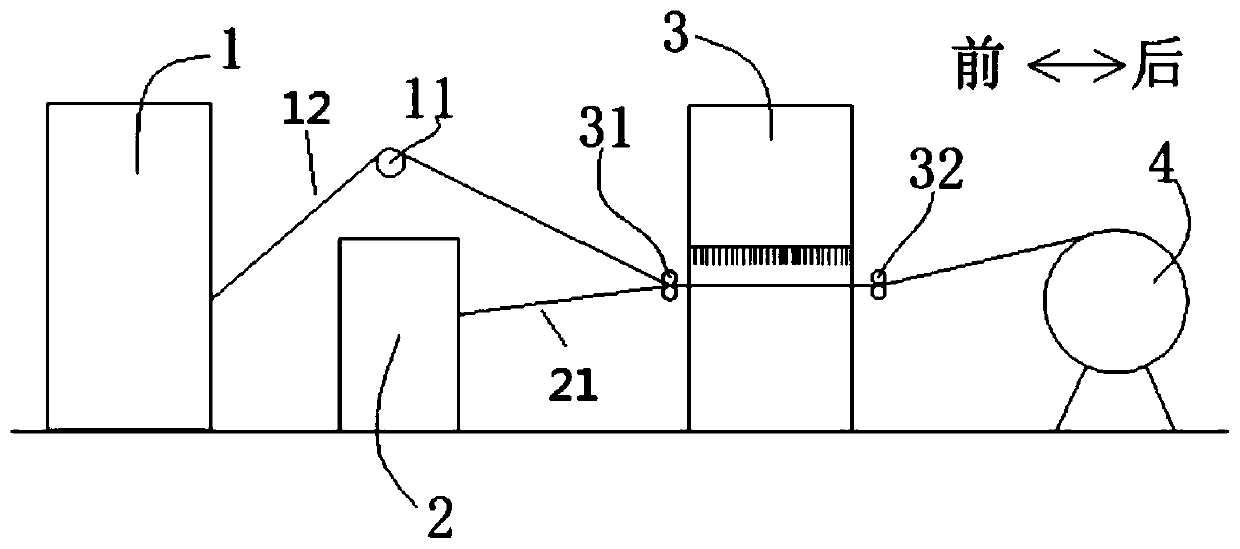

[0045] Such as image 3 As shown, the present embodiment provides a processing system for preparing warp-weft-knitted double-sided fabrics as described in Example 1, comprising a warp-knitting machine 1, a weft-knitting machine 2, a needle punching machine 3 and a cloth rolling machine 4, and the warp-knitting machine Knitting machine 1, weft knitting machine 2, needle punching machine 3 and cloth rolling machine 4 are sequentially arranged along the front and rear directions, and the warp knitted fabric woven by the warp knitting machine 1 passes above the weft knitting machine 2 and is connected with the The weft-knitted fabric woven by the weft-knitting machine 2 is superimposed up and down and passed through the processing section of the needle loom 3 for needle punching, and then is wound by the cloth winding machine 4. The processing system makes the lamination process of warp and weft knitted double-sided fabrics, the processing process is convenient and fast, and the t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com