Method for reducing noise of urban air rail train by using rubber wheels

A technology for aerial rails and rubber tires, which is applied to rails, wheels, and wheels featuring rail running parts, etc., can solve the problems of high maintenance cost and high construction cost.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

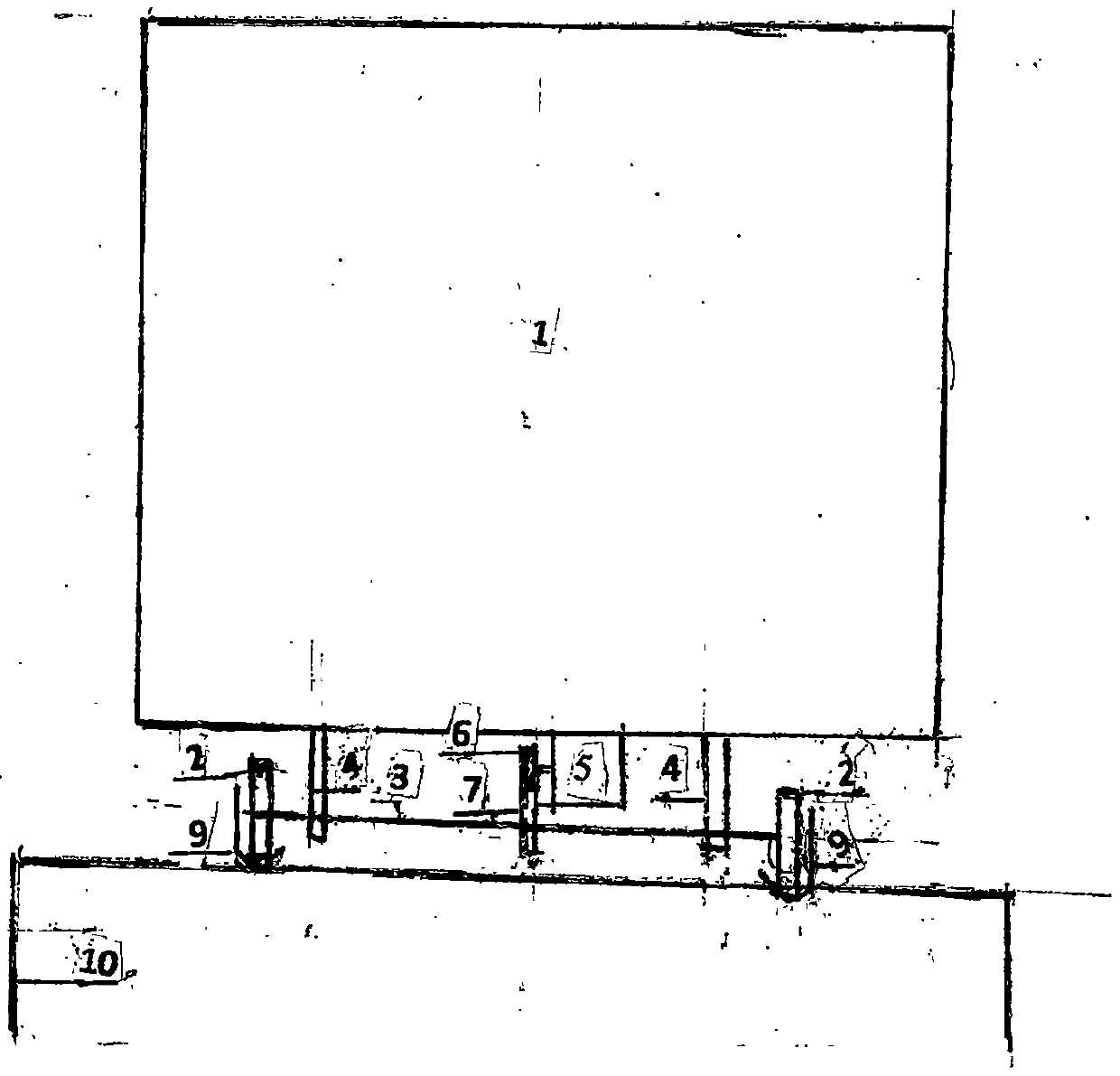

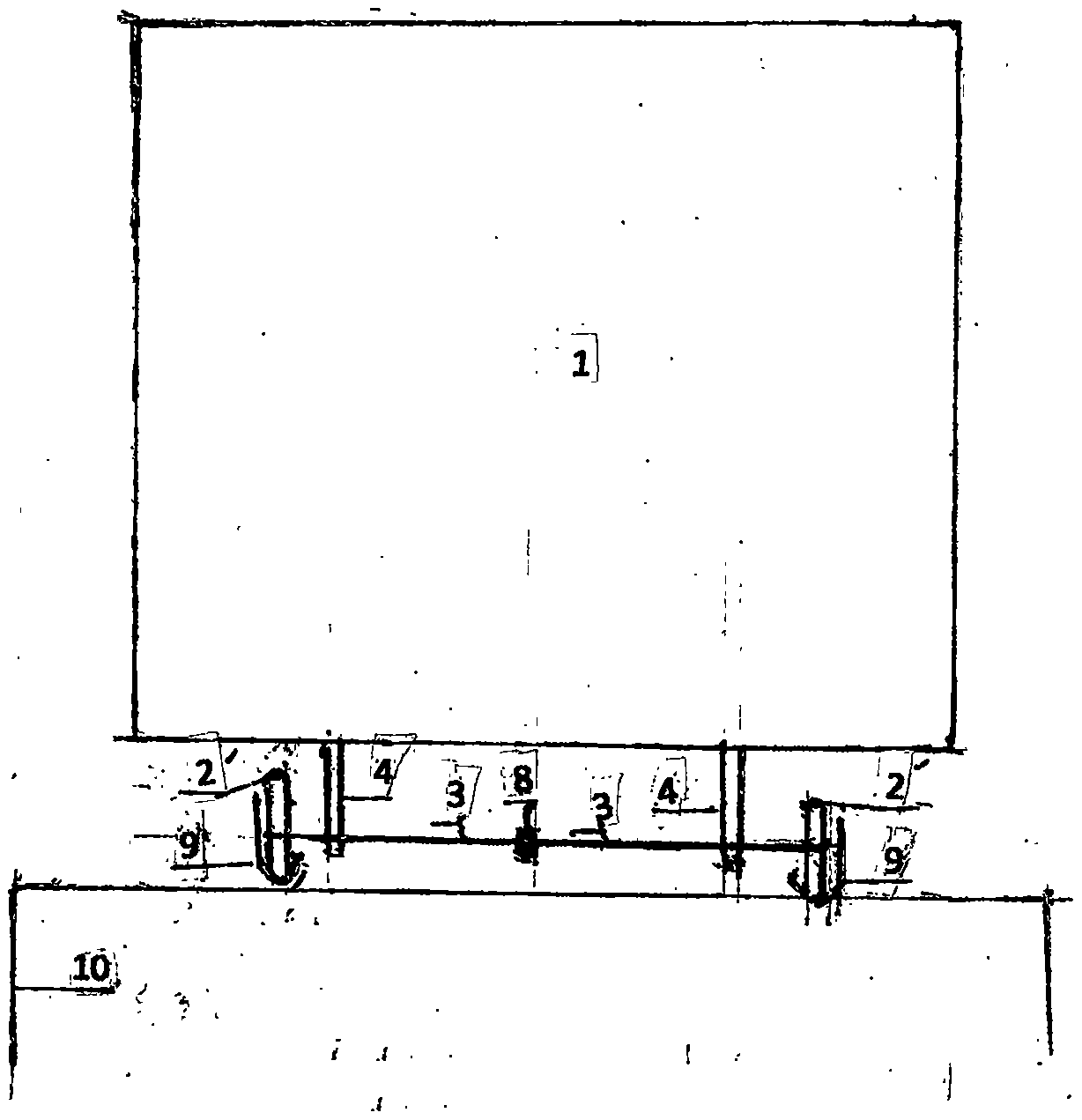

[0008] figure 1 and figure 2 Shown, the method that utilizes rubber wheel to reduce the noise that urban aerial rail train produces. The structure of the urban air rail train traffic is as follows: two legs of the door frame-shaped support frame 10 are arranged on both sides of the non-motorized vehicle lane, and two 'hook' shaped tracks 9 are housed on the crossbeam of the door frame shaped support frame 10, and the 'hook' shaped track 9 Copper strips are inlaid inside, and the 'hook' shaped track 9 is insulated from the crossbeam of the door frame-shaped support frame 10, and the positive and negative poles of the direct current are respectively connected to the copper strips installed in the two 'hook' shaped tracks 9; the 'hook' The upper half of the 'shaped track 9 is an insulating baffle. A permanent magnet synchronous motor 5 is installed on the front part of the train locomotive 1 bottom, and the driving gear 6 on the permanent magnet synchronous motor 5 axles is en...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com