Novel corrosion-resistant storage device for chemical raw materials

A technology for chemical raw materials and storage devices, applied in household refrigeration devices, packaging, transportation and packaging, etc., can solve the problems of labor consumption and low efficiency, and achieve the effect of reducing energy consumption, ensuring storage effect, and avoiding temperature changes.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

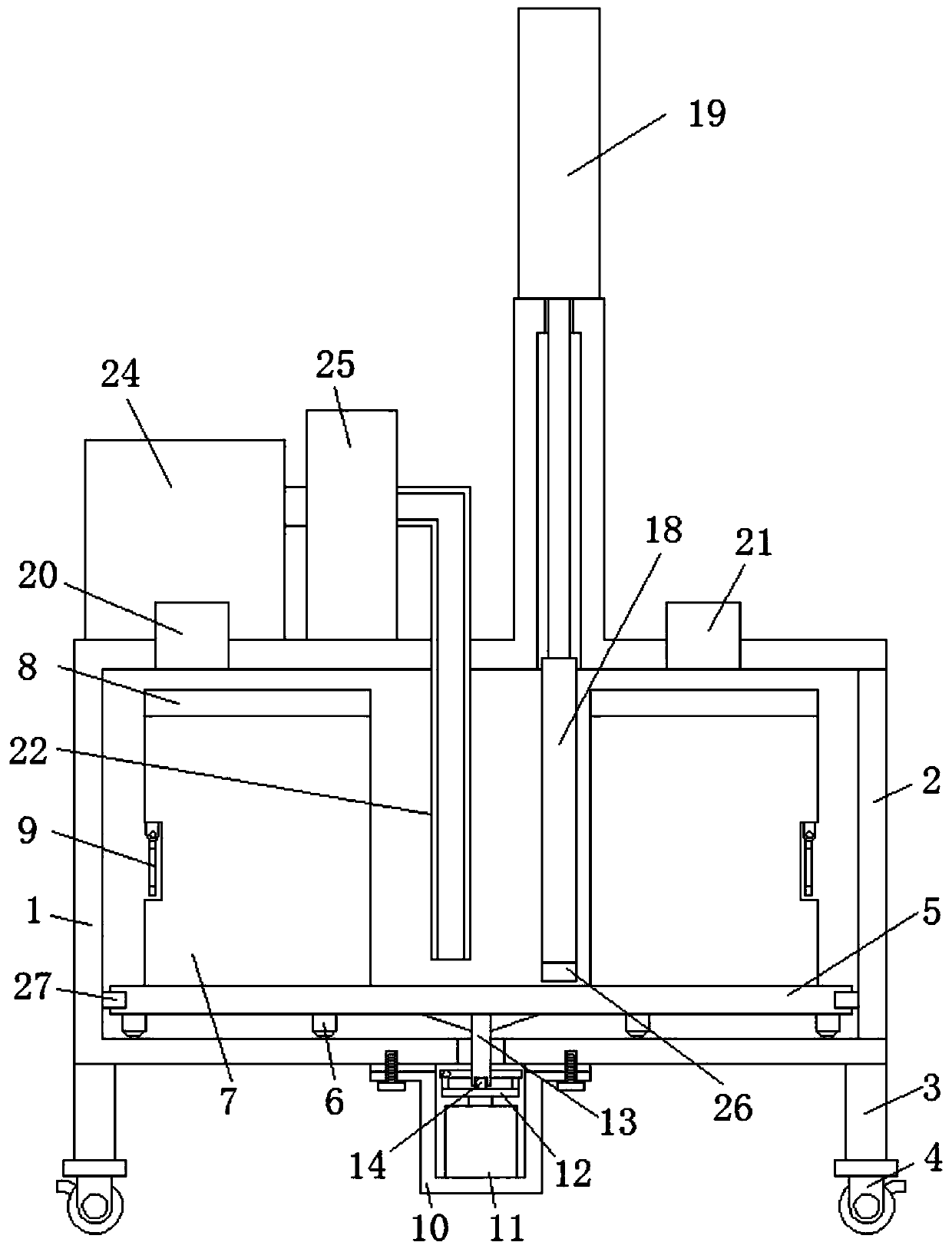

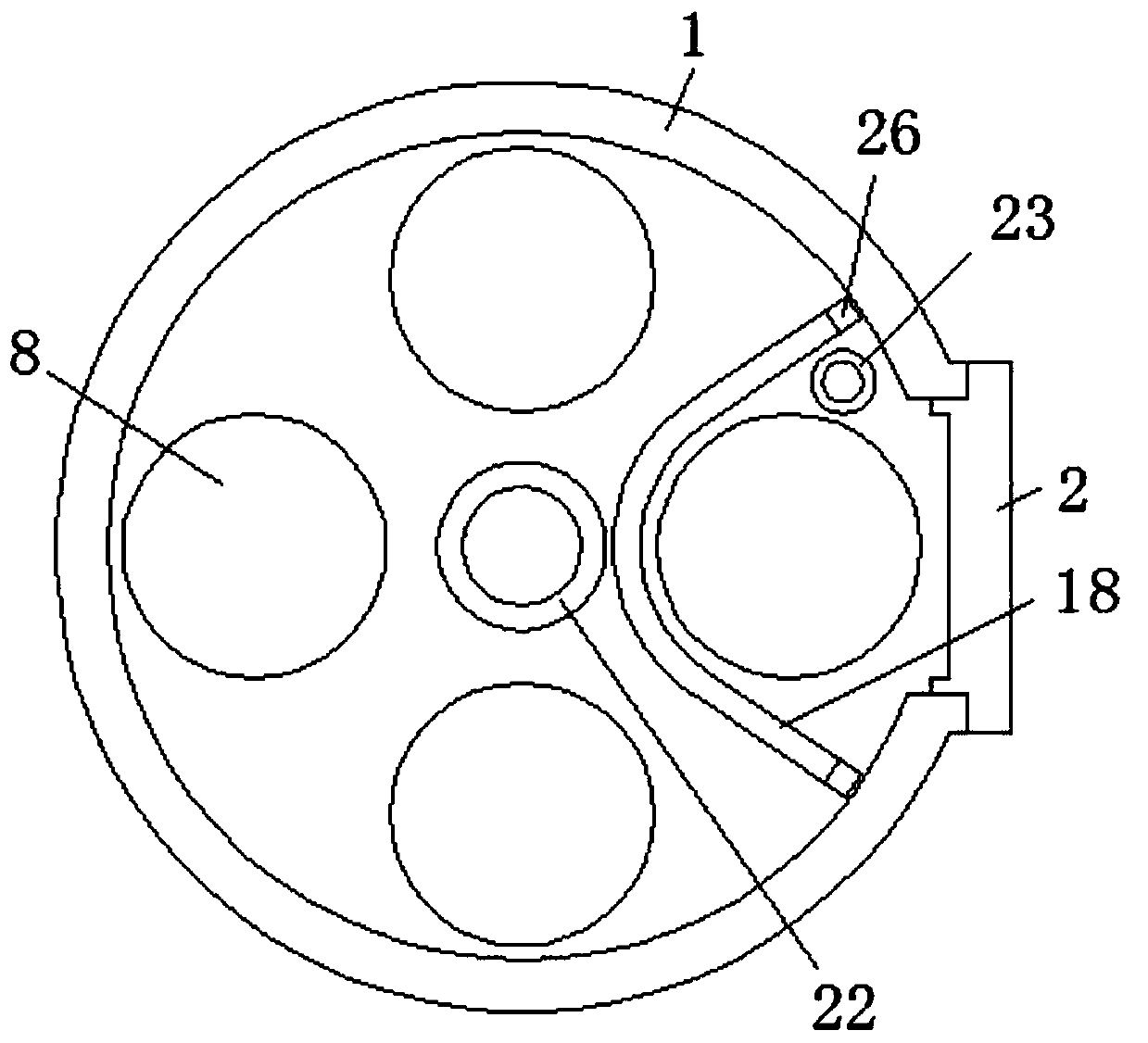

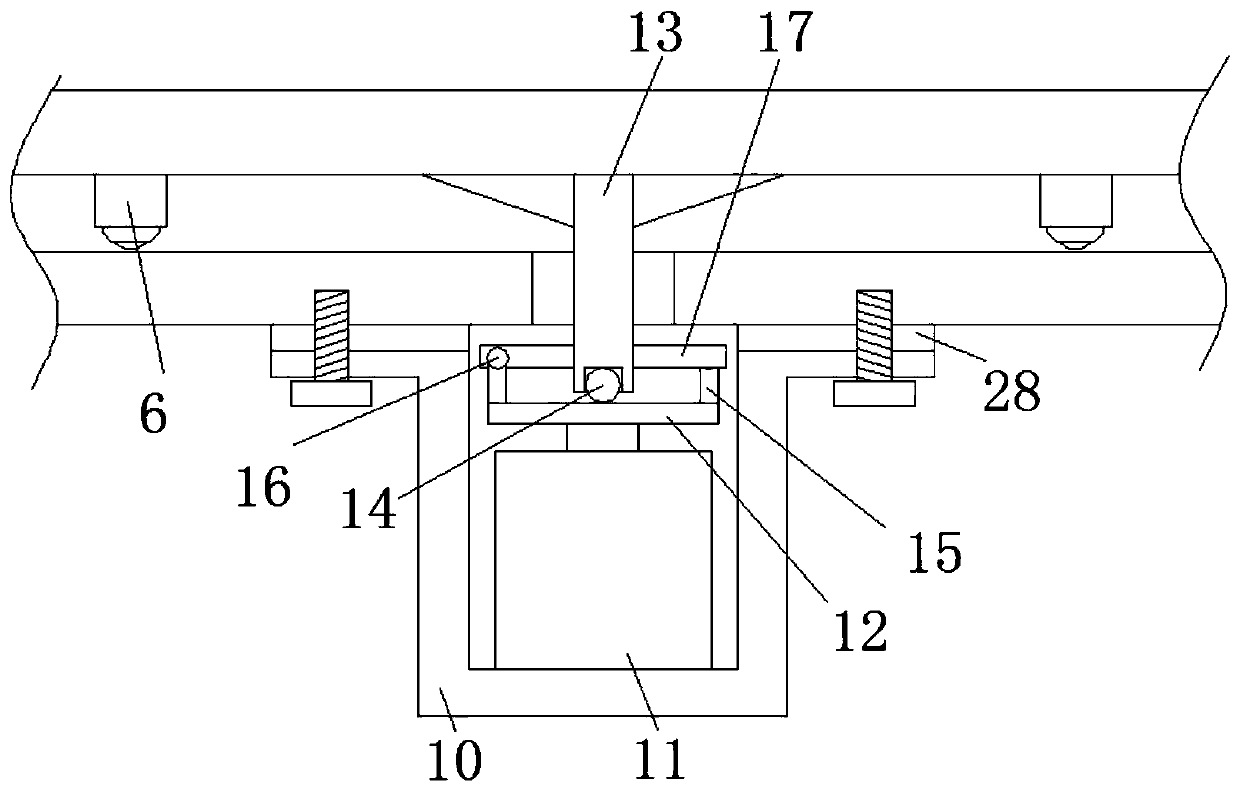

[0023] refer to Figure 1-4 , a new corrosion-resistant storage device for chemical raw materials, including a storage outer box 1, the storage outer box 1 is a cylindrical structure, and the vertical side of the storage outer box 1 is hinged with a side door 2, and the inner bottom of the storage outer box 1 The side is provided with a holding turntable 5, and the bottom side of the holding turntable 5 is provided with several universal balls 6, and the top side of the holding turntable 5 is equidistantly provided with several storage tubes 7, and the top airtight cover of the storage tube 7 is provided with There is a top cover 8, and one side of the storage tube 7 is provided with a hidden pull handle 9, and the middle part of the bottom side of the storage outer box 1 is fixedly connected with a power box 10, and the inner bottom side of the power box 10 is fixed with a rotating motor 11 by bolts to rotate. The output shaft of the motor 11 is fixedly connected with a conne...

Embodiment 2

[0026] Such as Figure 1-4 As shown, this embodiment is basically the same as Embodiment 1. Preferably, the two sides and the bottom side of the separator 18 are provided with gaskets 26 .

[0027] In this embodiment, the setting of the gasket 26 makes the space on both sides of the partition 18 belong to two independent spaces, avoiding the influence of the temperature on the inside of the storage outer box 1 and the outside of the partition 18 due to the opening of the side door 2 , at the same time, it also makes it faster and energy-saving to regulate the space inside the partition plate 18 with a large temperature difference.

Embodiment 3

[0029] Such as Figure 1-4 As shown, this embodiment is basically the same as Embodiment 1. Preferably, a sliding sealing ring 27 is provided between the vertical outer side of the storage carousel 5 and the inner wall of the outer storage box 1 .

[0030] In this embodiment, the setting of the sliding sealing ring 27 strengthens the airtightness of the storage outer box 1 and ensures the storage conditions.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com