Wet process phosphoric acid purification system and preparation process thereof

A purification system, wet-process phosphoric acid technology, applied in the fields of phosphorus compounds, inorganic chemistry, chemical instruments and methods, etc., can solve the problems of high impurities in phosphate rock, difficult comprehensive cost of phosphorus resource conversion, etc., so as to improve the extraction purity and production process. The effect of short process and high production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0040] The preparation technology of the wet-process phosphoric acid purification system provided by the invention comprises the following steps:

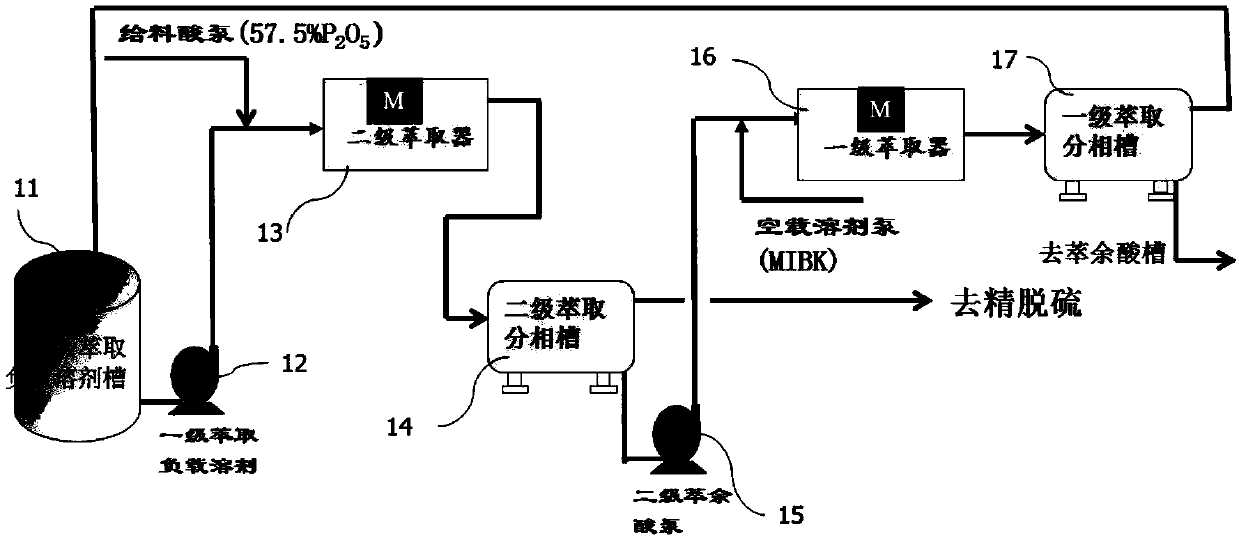

[0041] S1 is extracted in two stages in the extraction process section, so that the unloaded solvent and phosphoric acid are fully mixed, and the loaded solvent after extraction is phase-separated to separate the organic phase from the inorganic phase; after extraction, most of the phosphoric acid enters the organic phase; single series according to ( 4:1 ratio, that is 60m 3 / h of empty solvent and 15m 3 / h feed acid) for mixing, the temperature of the no-load solvent is controlled at 40±5°C, and the temperature of the feed acid is 60±5°C under no-load.

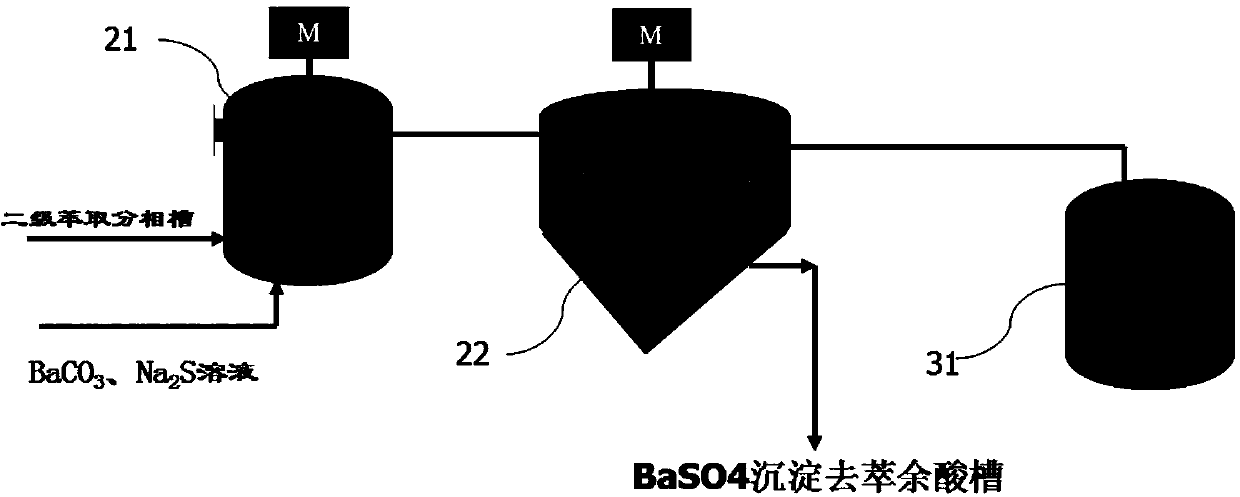

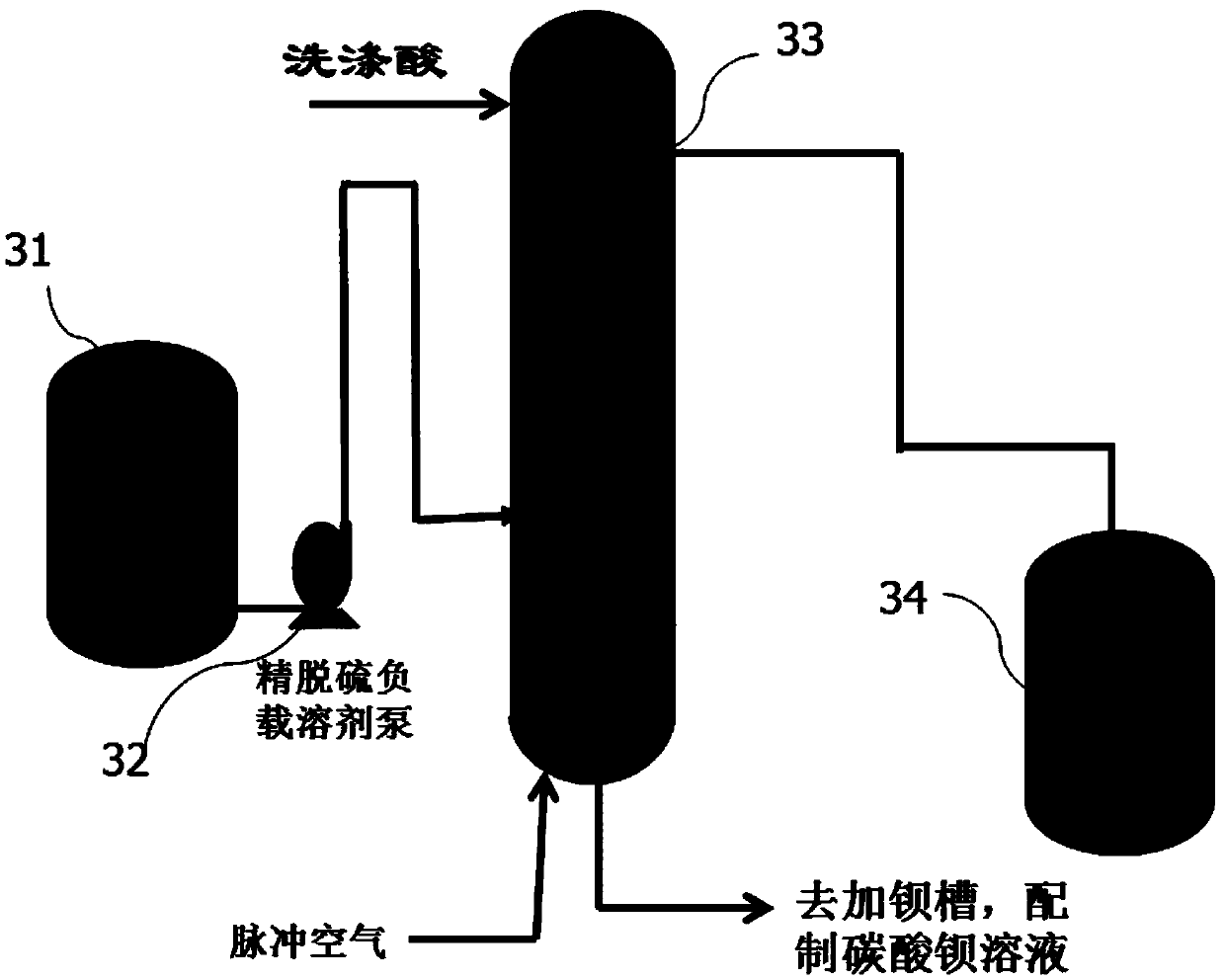

[0042] The organic phase after S2 S1 step separation reacts with BaCO3 back to acid to form BaSO4 precipitate, and then after sedimentation and separation, a fine desulfurization load solvent is obtained, and sulfate ions are further removed; the ratio of BaCO3 to load solvent i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com