A kind of environment-friendly quick-drying raw lacquer coating and preparation method thereof

A raw lacquer coating and raw lacquer technology, applied in the field of natural polymers, can solve the problems of shortening the drying and film forming time, and achieve the effects of shortening the drying and curing time, convenient operation, good application prospects and use value

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

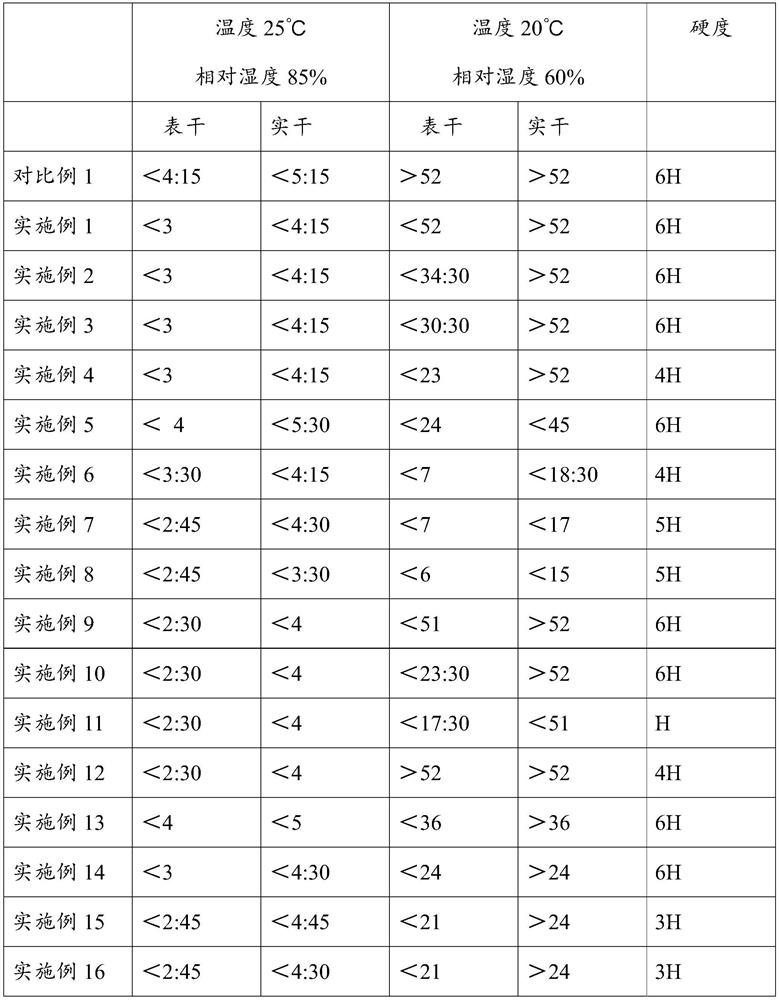

Examples

Embodiment 1

[0028] Example 1: Add 1 wt% ethylene glycol to the original raw lacquer emulsion, and stir at room temperature for 10min-30min to obtain a green hybrid raw lacquer coating.

Embodiment 2

[0029] Embodiment 2: Add 5wt% ethylene glycol to the original raw lacquer emulsion, and stir at room temperature for 10min-30min to obtain a green hybrid raw lacquer paint.

Embodiment 3

[0030] Embodiment 3: Add 8wt% ethylene glycol to the original raw lacquer emulsion, and stir at room temperature for 10min-30min to obtain a hybrid raw lacquer coating.

PUM

| Property | Measurement | Unit |

|---|---|---|

| quality score | aaaaa | aaaaa |

| quality score | aaaaa | aaaaa |

| quality score | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com