Energy-saving ventilation roof structure and construction method thereof

A construction method and top surface technology, applied in the direction of roof, roof ventilation, ventilation system, etc., can solve the problems of increased construction period cost and labor cost, long construction period, etc., achieve good economic and social benefits, good assemblability, cost saving effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0037] The present invention will be further described below in conjunction with the accompanying drawings, but not as a limitation of the present invention.

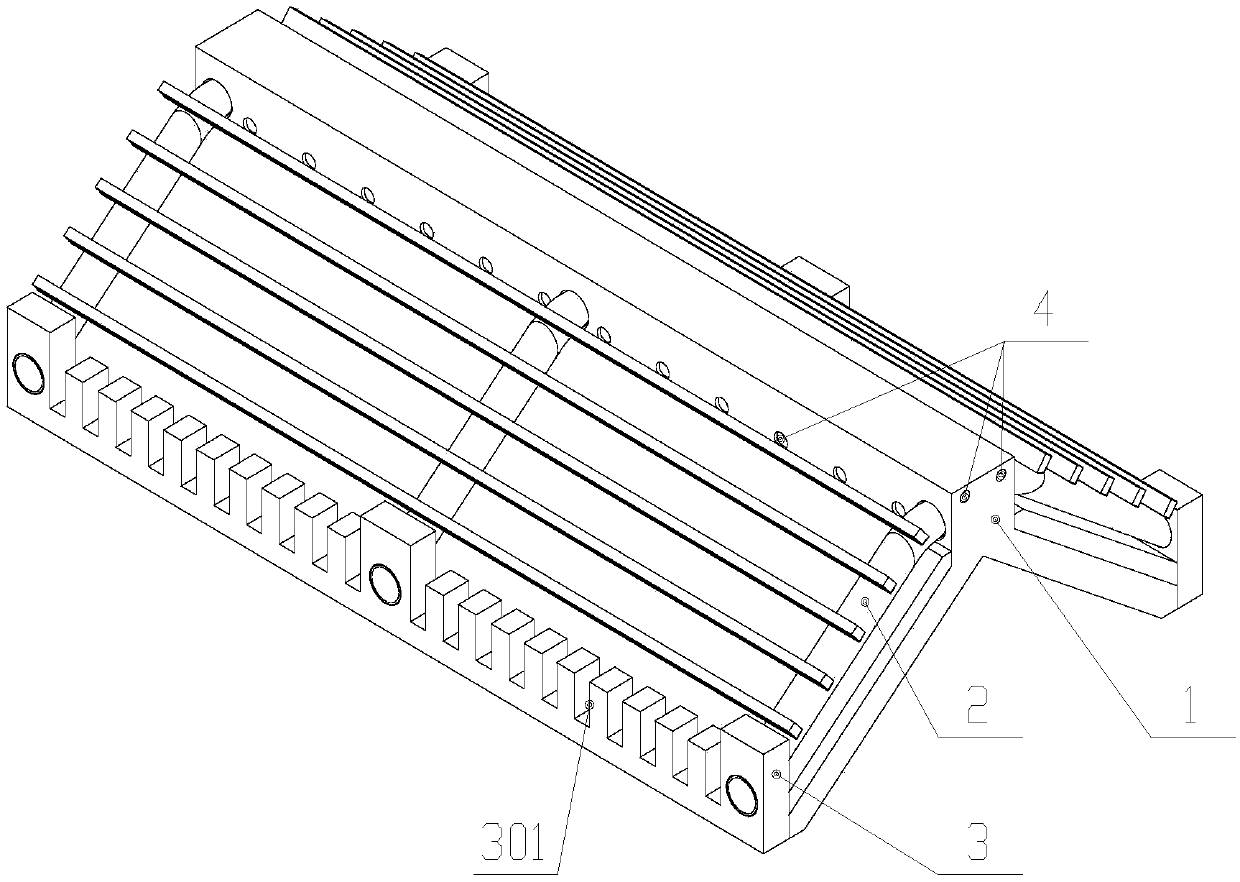

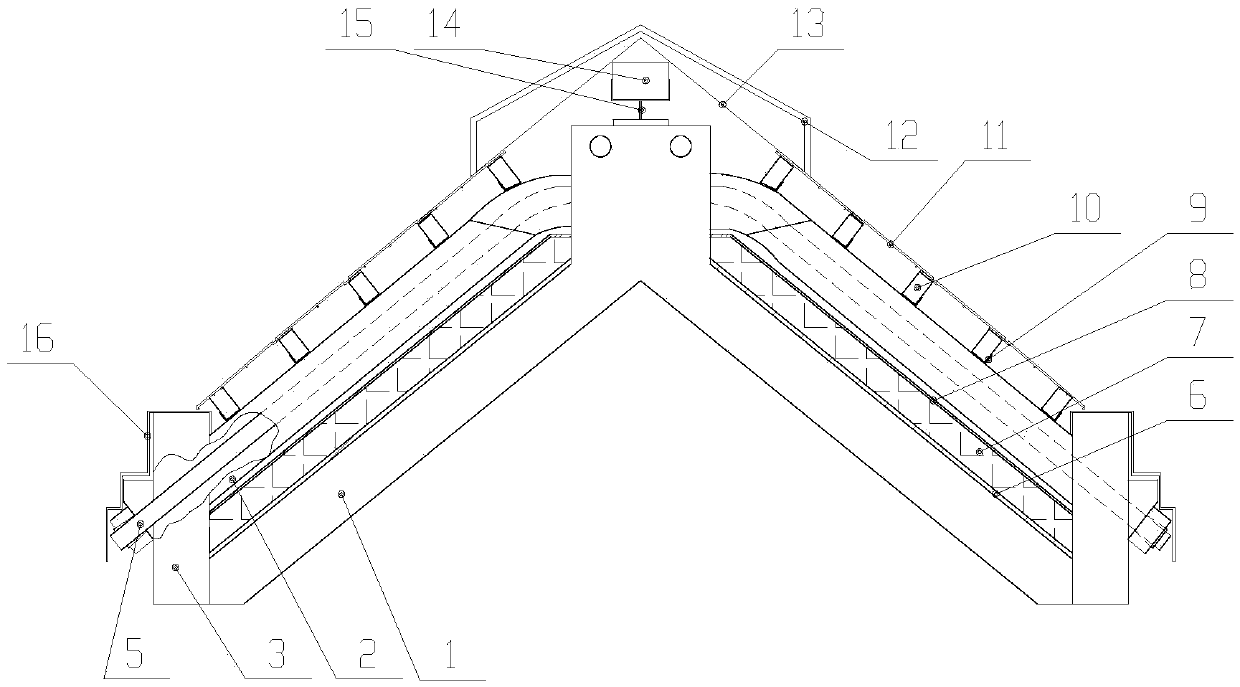

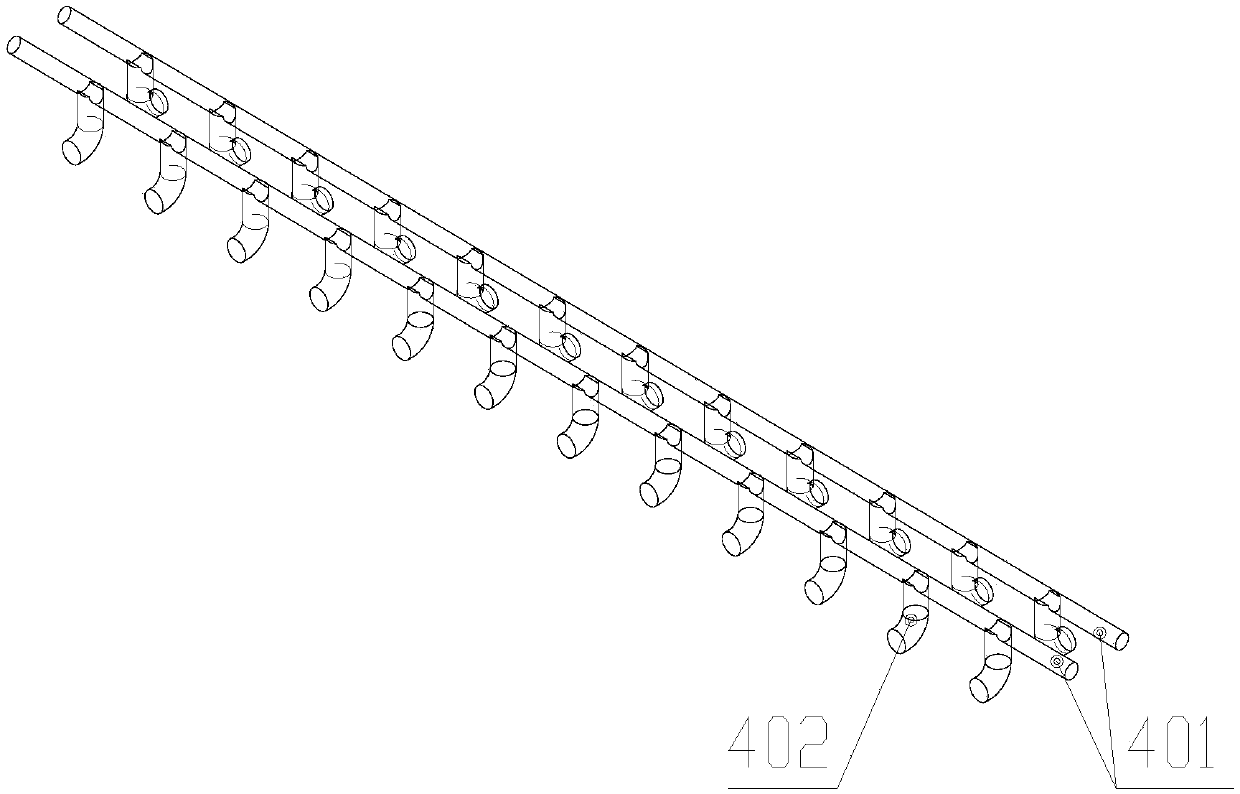

[0038] An energy-saving ventilated roof structure, comprising a man-shaped roof 1, a longitudinally arranged rectangular concrete body is arranged in the middle of the man-shaped roof 1, and several equidistant and transversely arranged cable guides 2 are arranged in the longitudinal direction of the rectangular concrete body. It is an inverted V-shaped structure, and the middle part of the inverted V-shaped structure is provided with a circular arc transition section; both ends of the man-shaped roof 1 are provided with fascia boards 3, and the fascia boards 3 are provided with inclined holes corresponding to the cable guides 2; The 3rd section of the fascia board between the cable conduits 2 is provided with a cornice retaining grate 301, and the rectangular concrete body is provided with a ventilation structure 4; the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com