Afterburner oil spraying device with high fuel oil regulation ratio

An afterburner and fuel adjustment technology, which is applied in the field of aviation power, can solve the problems of difficult debugging of joint matching work and high complexity of the oil circuit system, and achieve stable combustion, reduce system complexity, and reduce complexity.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

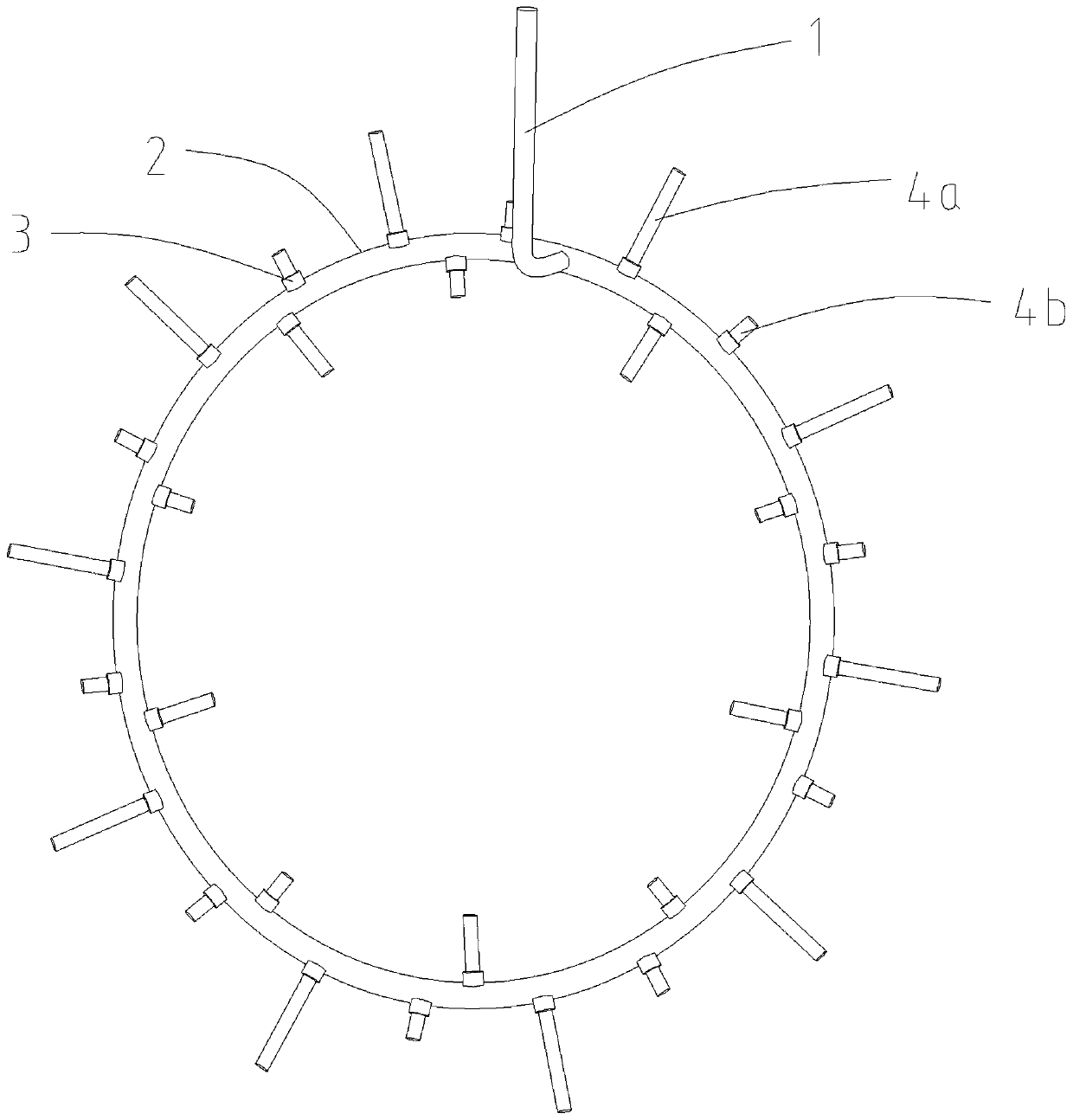

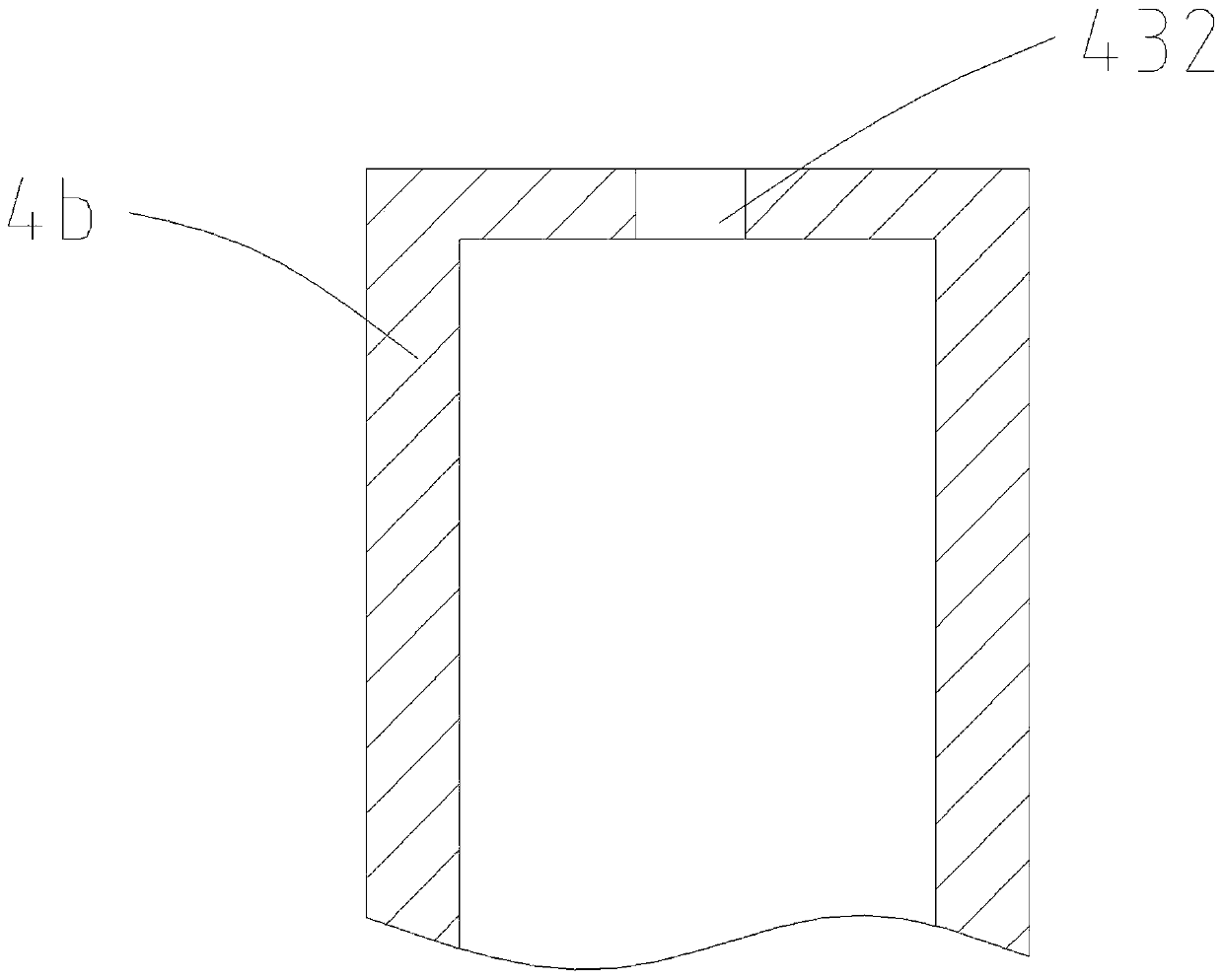

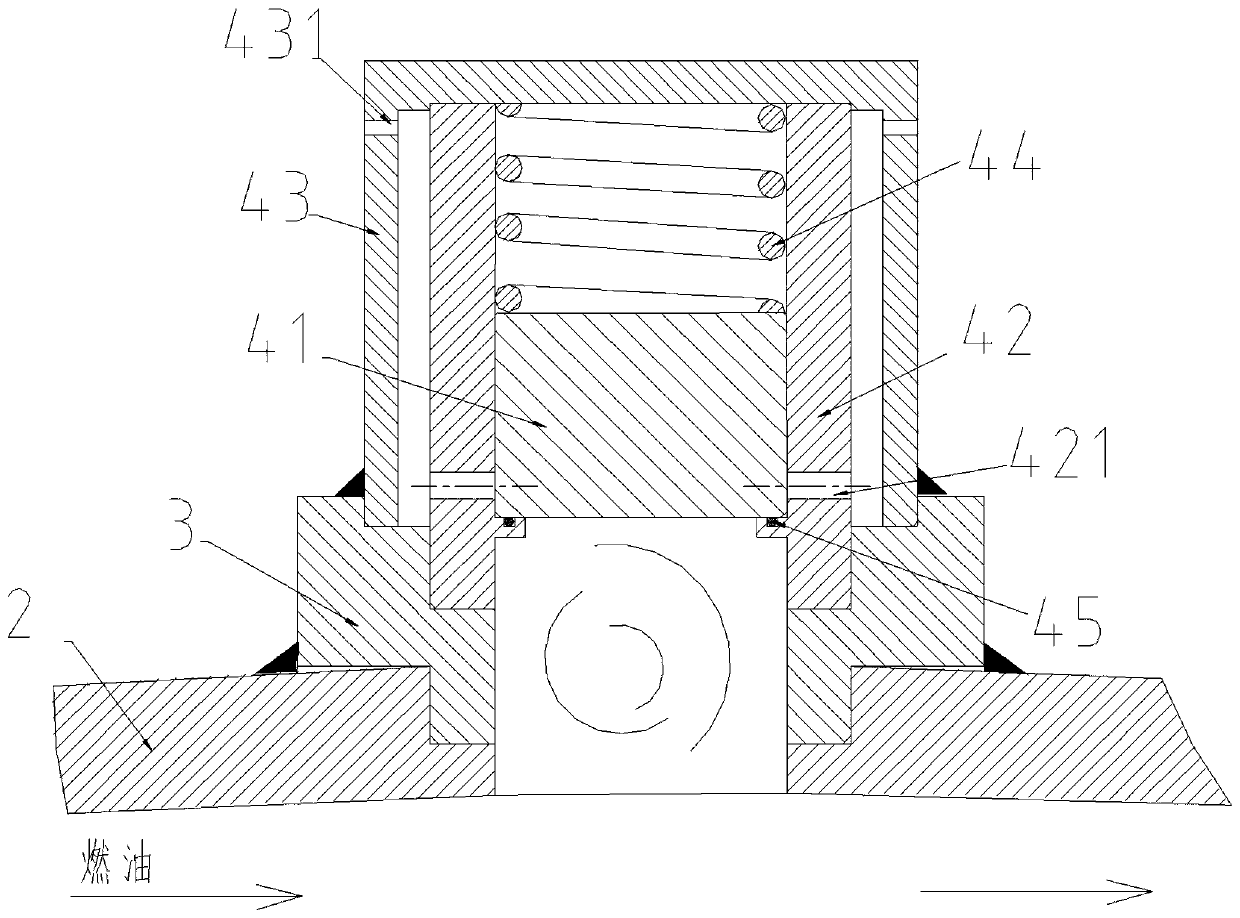

[0035] see Figure 1~6 , an afterburner fuel injection device with a high fuel adjustment ratio, comprising a ring pipe 2 and an oil inlet pipe 1 connected to the ring pipe 2, the inner and outer sides of the ring pipe 2 are provided with a plurality of tubular pipes around its circumferential direction Large fuel injection rod 4a, small fuel injection rod 4b, one end face of small fuel injection rod 4b away from ring pipe 2 is sealed and provided with first fuel injection nozzle 432, large fuel injection rod 4a includes the inner wall of fuel injection rods arranged at adjacent intervals 42 and the outer wall of the fuel injection rod 43, the inner wall of the fuel injection rod 42 and the outer wall 43 of the fuel injection rod are sealed away from one end face of the ring pipe 2, and the inner wall of the oil spray rod 42 is connected with the inner cavity of the ring pipe 2, and the outer wall of the oil spray rod 43 is connected with the ring pipe 2 Outer connection, the ...

Embodiment 2

[0038] This embodiment is further optimized on the basis of implementation 1, specifically:

[0039] A plurality of large oil injection rods 4a are evenly spaced on the inner and outer sides of the ring pipe 2 around its circumference, and small oil injection rods 4b are arranged between adjacent large oil injection rods 4a. The large oil injection rods 4a and the small oil injection rods 4b are alternately arranged at intervals.

[0040] As a preferred manner, the large oil injection rod 4a, the small oil injection rod 4b and the ring pipe 2 are all connected through the tubular adapter seat 3 . The conversion seat is tubular, and is connected with the ring pipe 2 by welding, and the conversion seat communicates with the inner cavity of the ring pipe 2, which avoids the problem of poor consistency in the installation and connection of the large fuel injection rod 4a, the small fuel injection rod 4b and the ring pipe 2.

[0041] As a preferred manner, the inner wall 42 of the l...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com