Mixed-flow type rice dryer

A dryer and mixed-flow technology, applied in dryers, drying, grain drying and other directions, can solve the problems of easy to produce waist burst, too fast drying speed, improper parameter selection, etc., and reduce the waist burst rate and reduce Operation steps, uniform heating effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

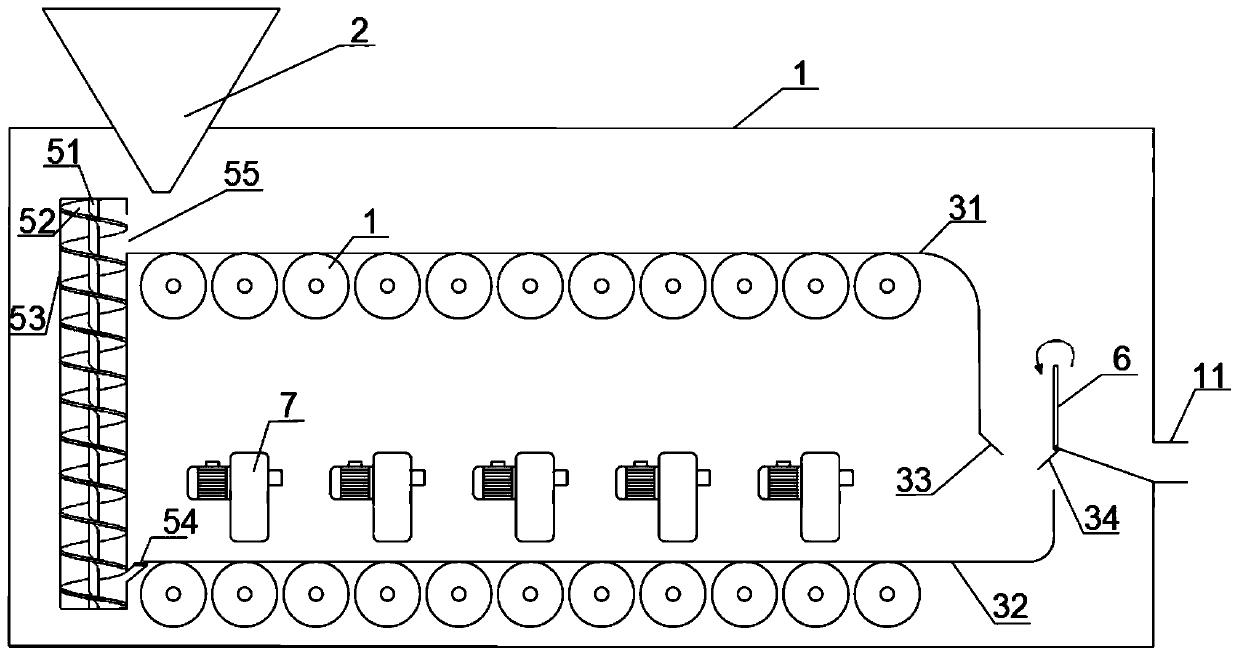

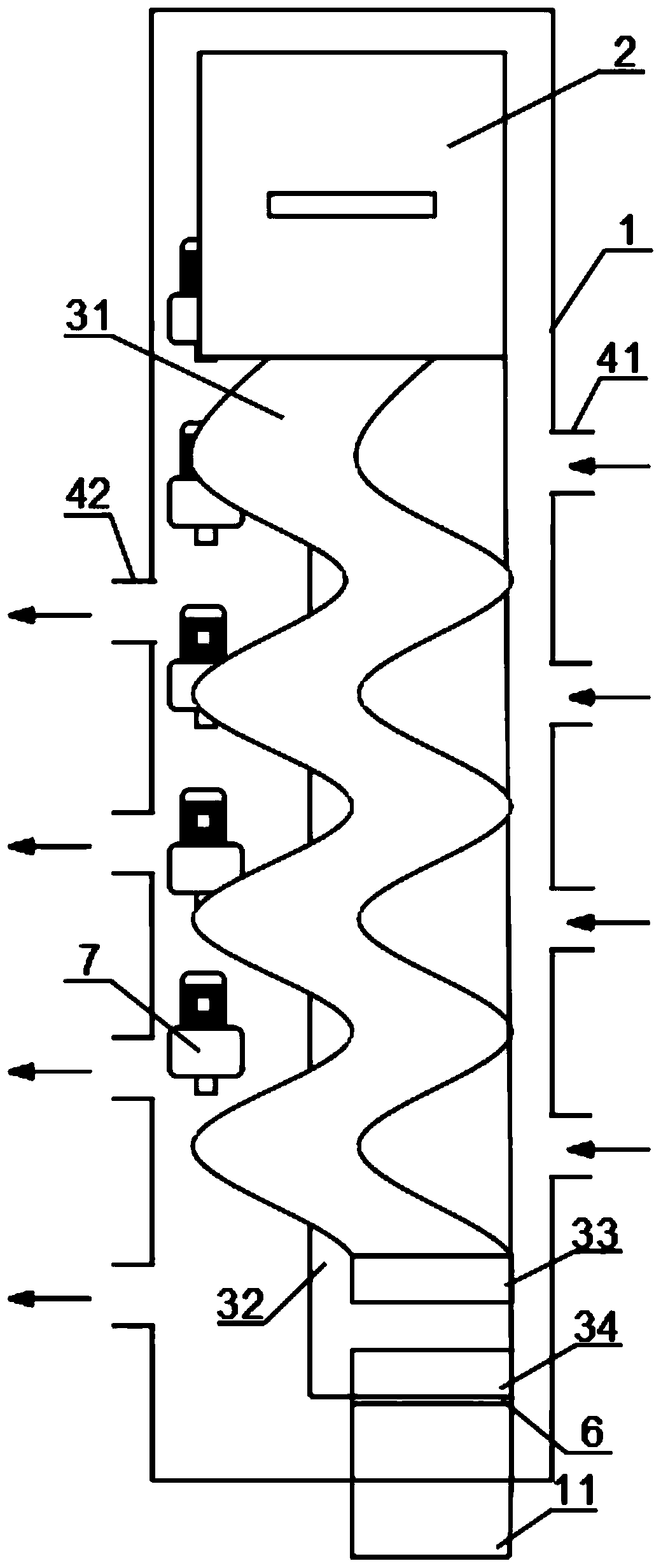

[0028] see Figure 1 to Figure 2 , the present invention provides a mixed-flow rice dryer, which includes a box body 1 and a hopper 2 opened on the box body 1, and also includes a conveyor belt mechanism, which includes a curved first conveyor belt 31 and is located below the first conveyor belt 31. The second conveyor belt 32; in the horizontal direction, the front end of the first conveyor belt 31 is located in front of the second conveyor belt 32, and the end of the first conveyor belt 31 is located in front of the second conveyor belt; it also includes mixed flow tuyere, which includes a A plurality of air inlets 41 and air outlets 42 on two opposite side walls; in the horizontal direction, the air outlet 42 is located between every two air inlets 41; the mixed flow air outlet is located above the first conveyor belt 31; it also includes a lifting mechanism, which It includes a vertically arranged central rod 51, a helical blade 52 that spirals up and surrounds the outer c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com