Fuzzy control method and control system for temperature of fluidized bed product, and fluidized bed system

A fuzzy control system and fuzzy control technology, applied in the fields of medicine and food packaging, can solve problems such as difficulties, achieve the effect of improving drying efficiency, avoiding inaccurate temperature control and ensuring stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

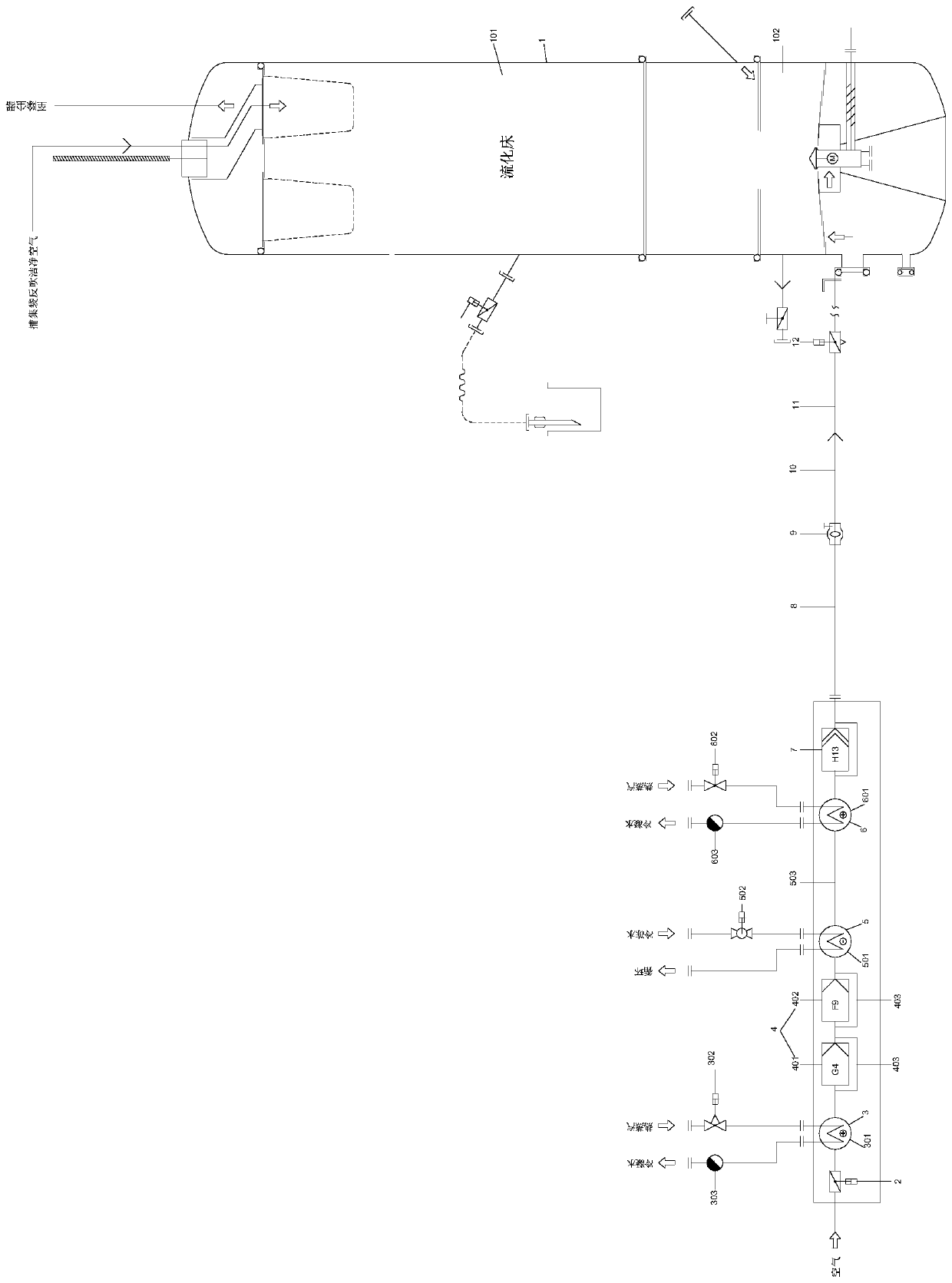

[0029] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

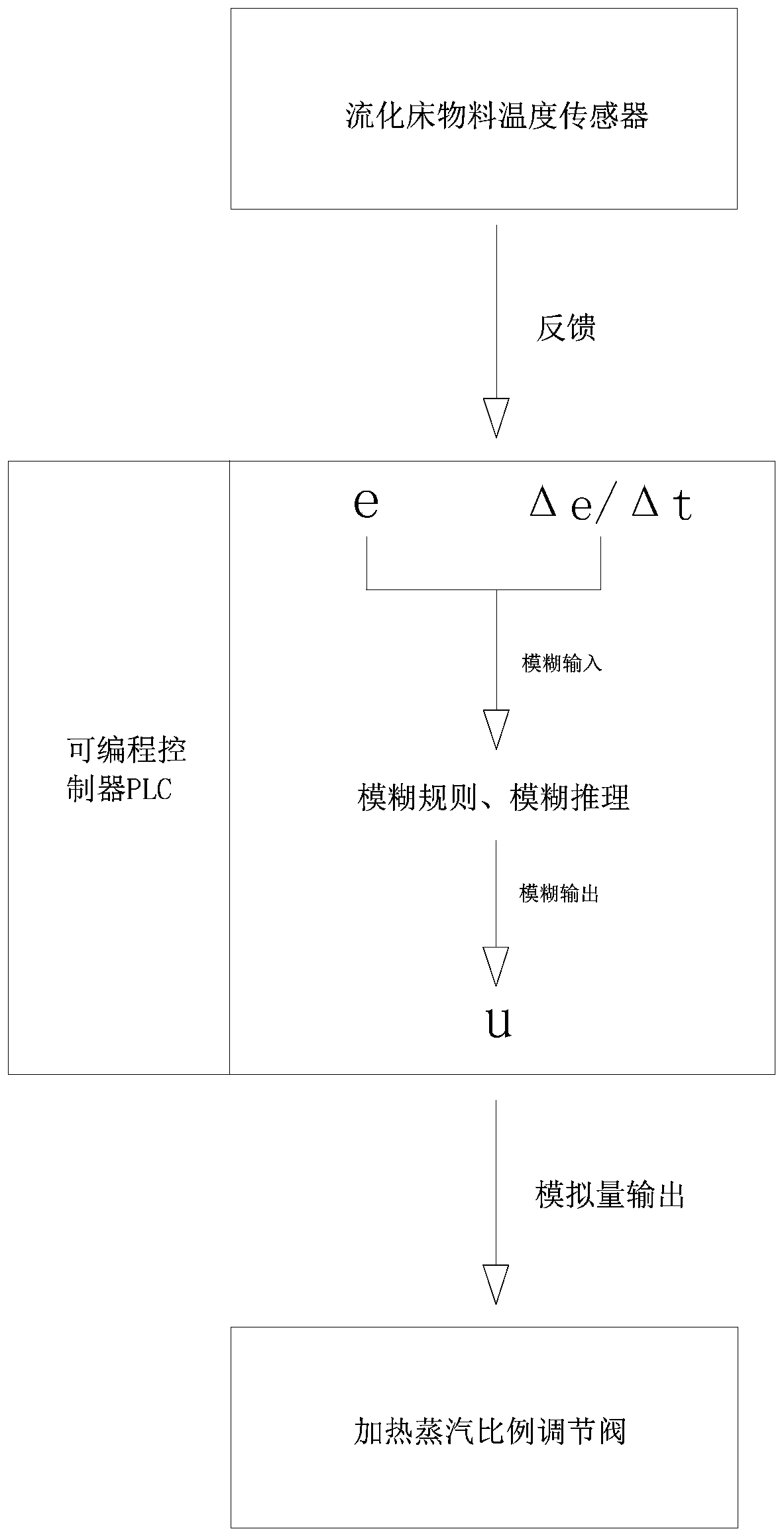

[0030] like figure 1 and figure 2 As shown, the fuzzy control method of the fluidized bed product temperature of the present embodiment comprises:

[0031] S01, obtaining the product temperature in the fluidized bed 1;

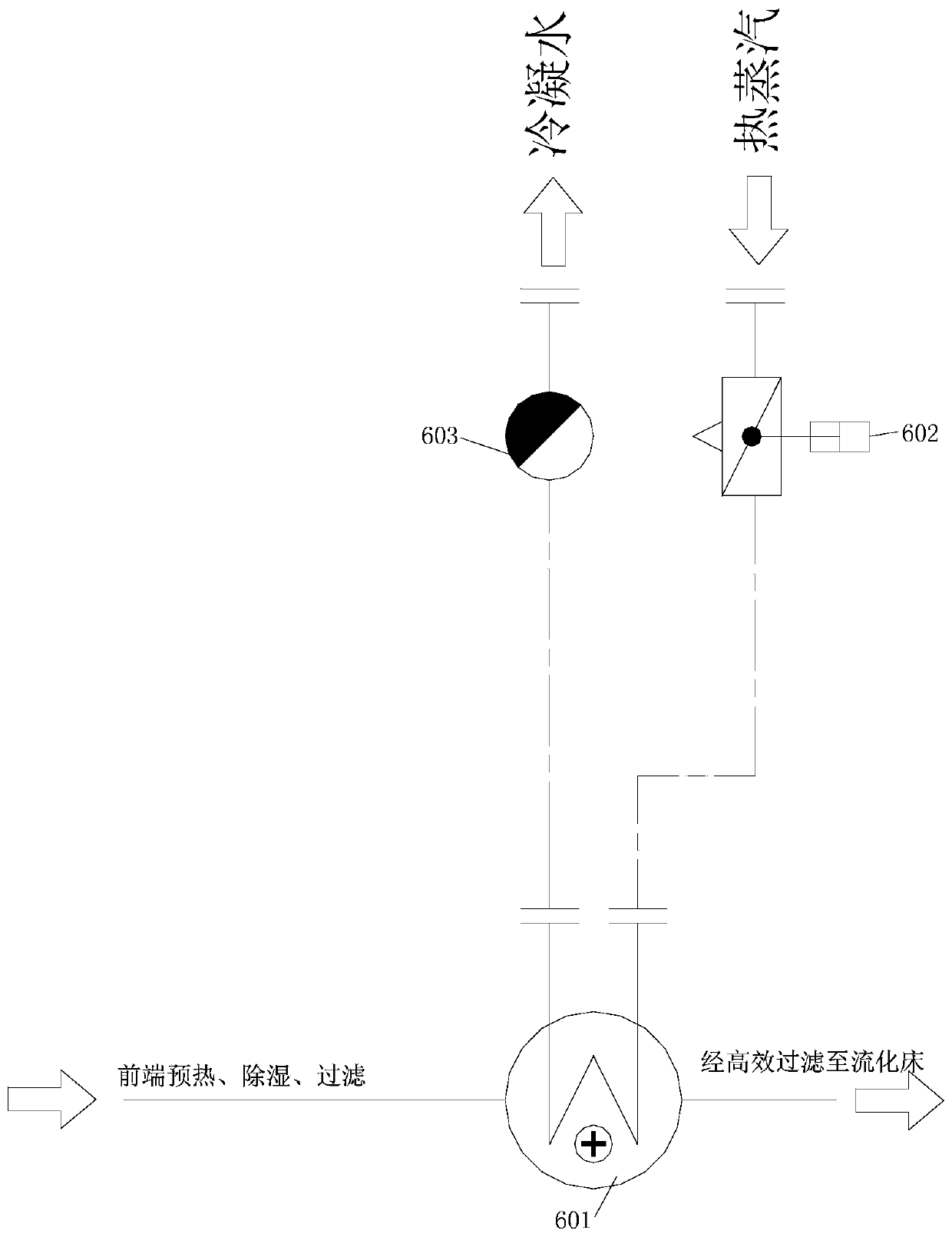

[0032] S02. According to the deviation e between the product temperature and the preset temperature and the deviation change rate Δe / Δt within a unit time Δt, perform fuzzy control on the opening u of the heating steam proportional regulating valve 602 of the heating unit 6 to make the fluidization The product temperature in the bed 1 is in a constant range; where the heating unit 6 is used to heat the air entering the fluidized bed 1 .

[0033] In this embodiment, in step S02, the deviation e and the deviation change rate Δe / Δt are used as the fuzzy input, and the opening of the heating steam proportional regulating valve ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com