Data acquisition method for automatic transmission offline test system

A technology of automatic transmission and test system, which is applied in the direction of machine gear/transmission mechanism testing, etc., can solve the problem of uncertainty of sensor sampling frequency, and achieve the effect of smooth and stable detection data, obvious correlation, and saving computing resources.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

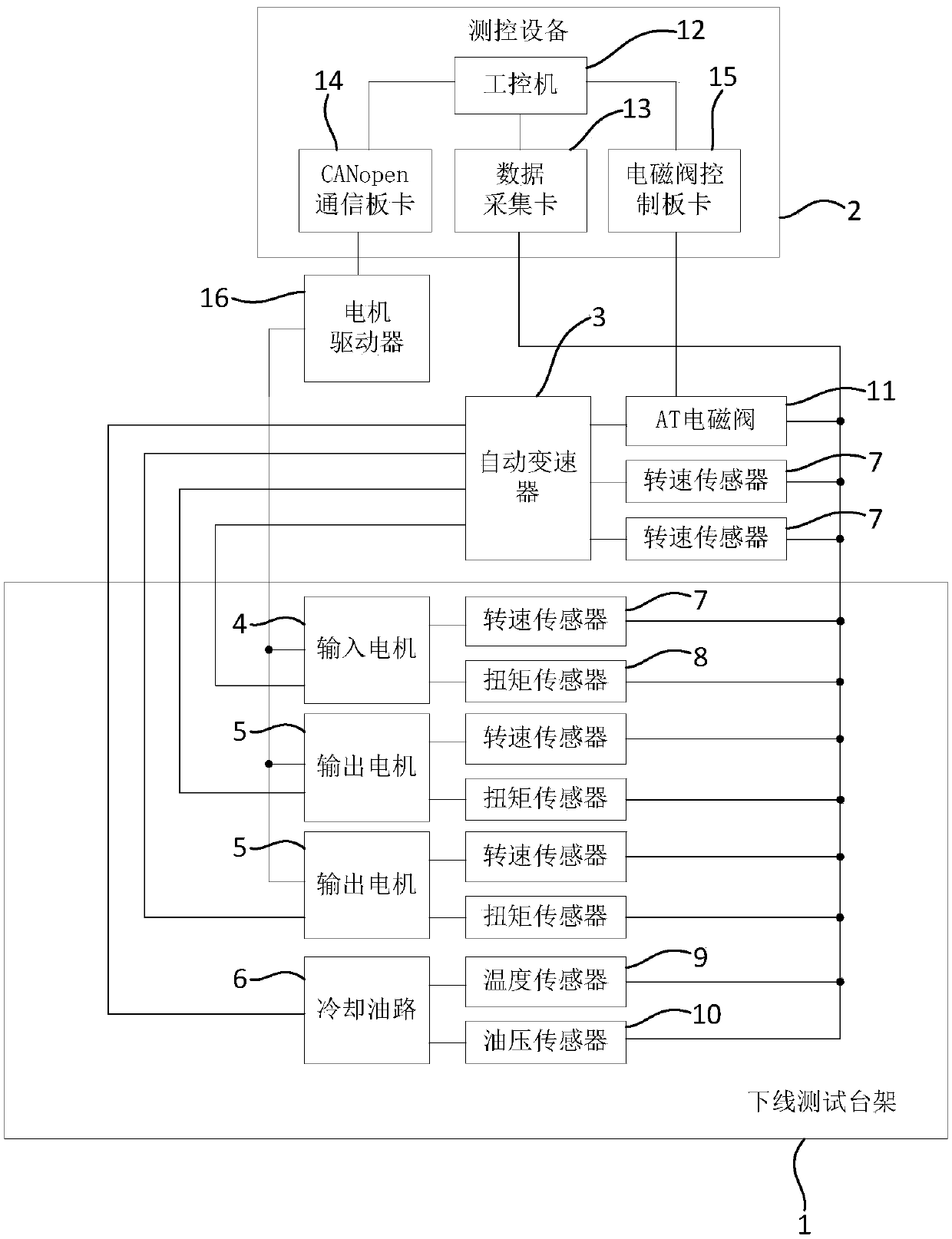

[0037] Embodiment 1: as figure 1 As shown, this embodiment specifically relates to a data collection method for an automatic transmission off-line test system. The automatic transmission off-line test system is used for the off-line test of the automatic transmission (AT transmission). The automatic transmission off-line test system includes the off-line test bench 1 and the measurement and control equipment 2 .

[0038] The end-of-line test bench 1 is used to carry the automatic transmission 3 to be tested. The end-of-line test bench 1 includes an input motor 4 and two output motors 5 . The input motor 4 is used to connect to the input shaft of the automatic transmission 3 , and the two output motors 5 are respectively connected to the two output shafts of the automatic transmission 3 . The input motor 4 is used to drive the automatic transmission to rotate, and the output motor 5 is used to simulate the load of the output shaft. The off-line test bench 1 is provided with ...

Embodiment 2

[0070] Embodiment 2: The main difference between this embodiment and Embodiment 1 is that the method used for determining the stability of the oil pressure is different. In this embodiment, the industrial computer 12 of the measurement and control device 2 performs a stability determination that specifically includes the following steps:

[0071] (1) Select several continuously acquired detection data from the detection data of the oil pressure sensor 10 to form the oil pressure detection data set {Xi}; in this embodiment, the oil pressure detection data set {Xi} includes 20 continuously acquired Test data;

[0072] (2) Determine whether the oil pressure is stable through the oil pressure detection data set {Xi}; in this process, record the first acquired detection data X1 in the oil pressure detection data set {Xi} as the initial value, if the oil pressure detection If each detection data Xi in the data set {Xi} is within the range of (a1, a2) and within the range of (X1+b1, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com