Nitrogen content detection method for infant formula milk powder

A detection method and technology for infant formula, which are applied in the direction of testing food, material inspection products, testing dairy products, etc., can solve the problem of difficulty in grasping the first-hand information of milk powder, and save indexing time, indexing time and indexing burden, saving The effect of index burden

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

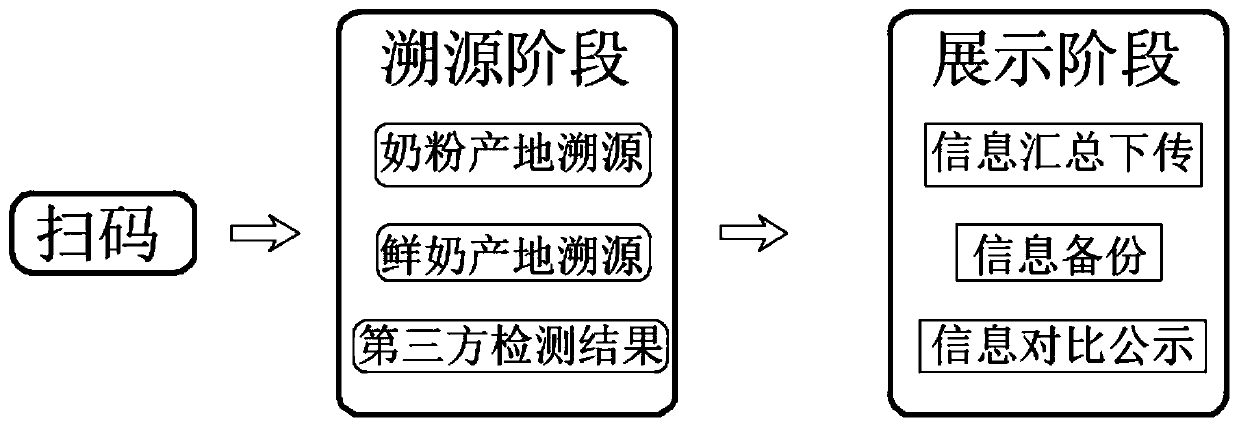

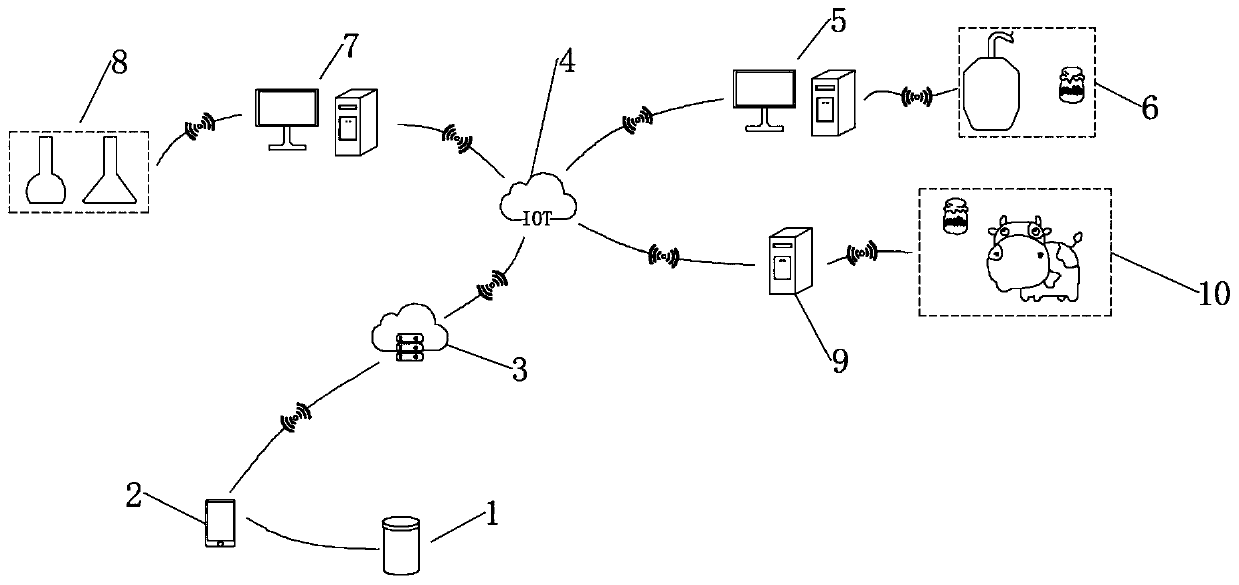

[0036] see figure 1 , a method for detecting the nitrogen content of infant formula milk powder mainly comprises the following steps:

[0037] S1, scan the code, the user uses the mobile terminal 2 carried by himself, which can be a mobile phone, to scan the QR code of the commodity 1 of the baby milk powder body to be detected, obtain the batch information of the baby milk powder body 1, and transmit the batch information to the cloud on the storage 3, and then uploaded to the IoT module 4 by the cloud storage 3;

[0038] S2. Trace the origin of milk powder. After receiving the batch signal uploaded by the cloud storage 3, the Internet of Things module 4 starts to retrieve relevant information about the origin of milk powder. The Internet of Things module 4 retrieves the production information of the application batch through the milk factory detection and processing terminal 5 , including the production date of the product, fresh milk entry quality inspection information an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com