Detection method for illumination uniformity of photo-etching machine

A technology of illumination uniformity and detection method, which is applied in the field of lithography machines, can solve the problems of inability to detect in real time, time-consuming, low efficiency, etc., and achieve the effects of low cost, improved accuracy, and improved detection efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

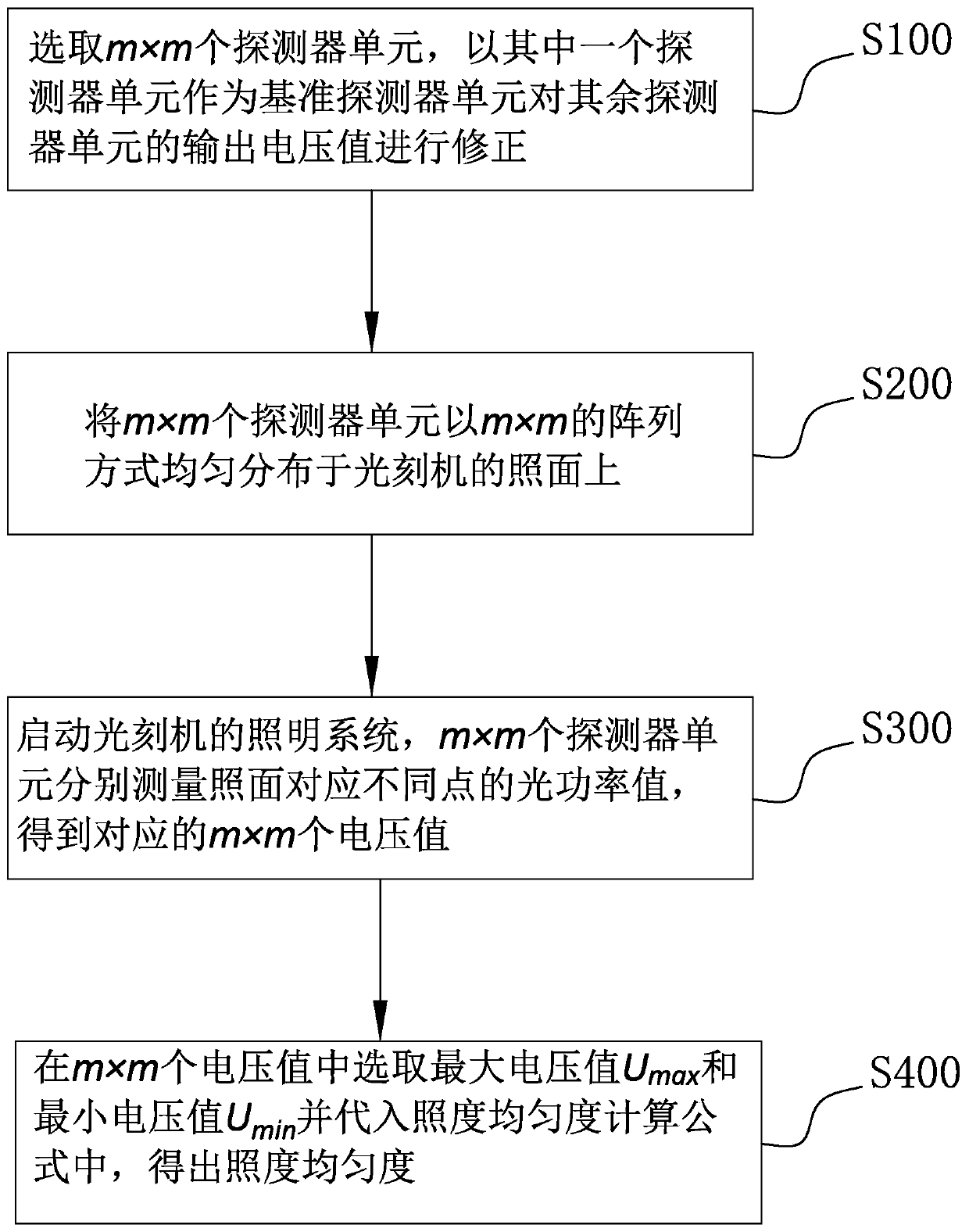

[0035] refer to figure 1 , which is a preferred embodiment, a method for detecting the uniformity of illuminance of a photolithography machine, comprising:

[0036] S100. Select m×m detector units, and use one of the detector units as a reference detector unit to correct the output voltage values of the remaining detector units;

[0037] S200, evenly distributing m×m detector units on the illumination surface of the lithography machine in an m×m array;

[0038] S300. Start the lighting system of the lithography machine, and measure the optical power values corresponding to different points on the illuminated surface with m×m detector units to obtain corresponding m×m voltage values;

[0039] S400. Select the maximum voltage value U from the m×m voltage values max and the minimum voltage value U min And substituting it into the calculation formula of illuminance uniformity, the illuminance uniformity of the photolithography machine under the current optical power value i...

Embodiment 1

[0064] Embodiment 1, the size of the photolithography machine is 32 inches, and 3×3 detector units are used:

[0065] First of all, for the convenience of distinction, the nine detector units are recorded as the first detector unit, the second detector unit, the third detector unit, the fourth detector unit, the fifth detector unit, and the sixth detector unit , the seventh detector unit, the eighth detector unit and the ninth detector unit.

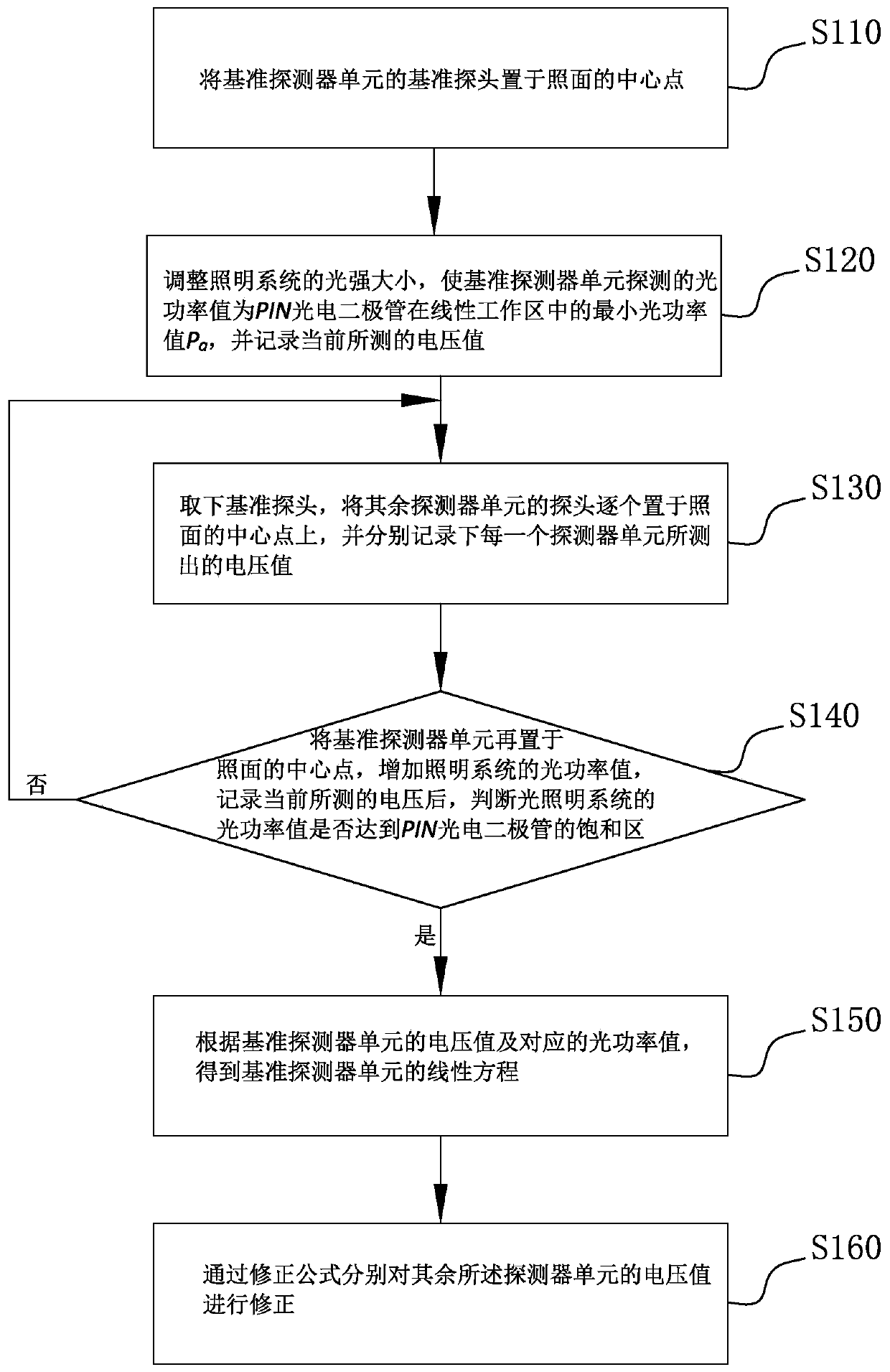

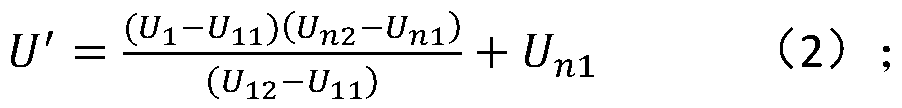

[0066] First, one of the detector units is selected as the reference detector unit, in this embodiment, the first detector unit is selected as the reference detector unit, and then the correction is performed according to steps S110 to S160, then the first detector unit can be obtained Linear equations, and get the correction formulas of the second to ninth detector units respectively.

[0067] Among them, according to the voltage value measured by the first detector and the corresponding optical power value, it can be obtained that the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com