Optical and thermal infrared multi-stage imaging detection method and device for defects of transparent component

A technology of thermal infrared imaging and imaging detection, which is applied in measuring devices, material defect testing, optical radiation measurement, etc., can solve problems such as small size, many types, and insignificance, and achieve improved accuracy, effective defect identification, and information volume rich effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific example

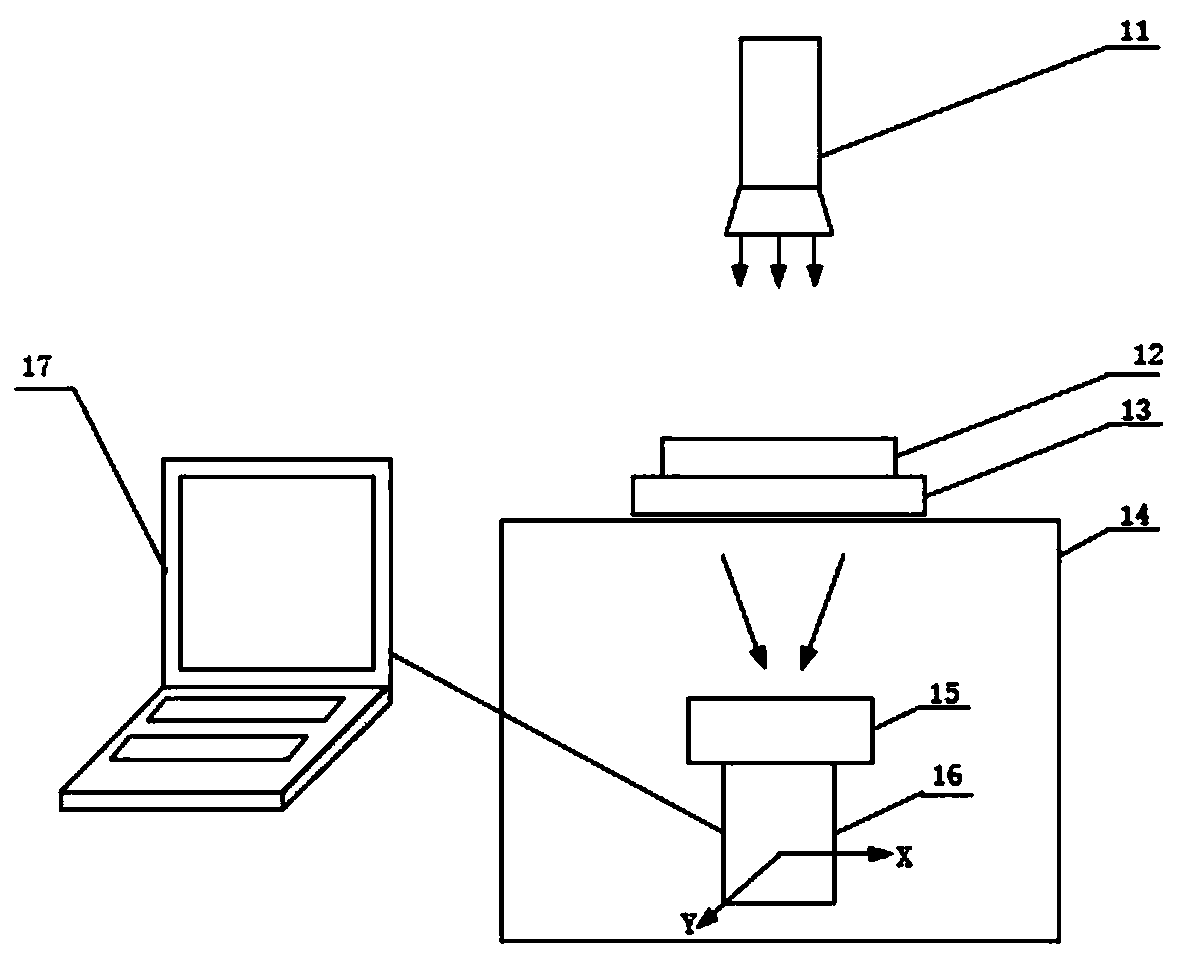

[0085] S1, use two ultra-depth-of-field infrared modules to perform thermal infrared imaging on 3C transparent components, and perform interval sampling on the two imaging videos obtained, each extracting 7 frames of 60×40 pixel video, a total of 60×40 pixel size, 7 frames 2 sections of video, namely the first infrared video and the second infrared video;

[0086] S2, using the first convolutional neural network (3D-CNN) model to extract data features from the first infrared video and the second infrared video, and calculate the probability of belonging to different defect categories, the defect categories include normal, cracks, bubbles, scratches, Chipping;

[0087] S3. Compress the size of the optical imaging image to 60×40 pixels, and randomly extract 2 pictures from the imaging videos of the two ultra-depth-of-field infrared imaging modules, a total of 4 infrared forming images, all of which are 60×40 pixels in size, so as to obtain a total 5 images of 60×40 pixels;

[...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com