Automatic inspection method for structure size of arc hinge joint of assembled culvert segment

An automatic inspection and assembly technology, applied in 3D image processing, image data processing, instruments, etc., can solve the problems of low measurement efficiency, high measurement difficulty, and low measurement accuracy, and achieve the goal of improving accuracy and reducing measurement workload Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

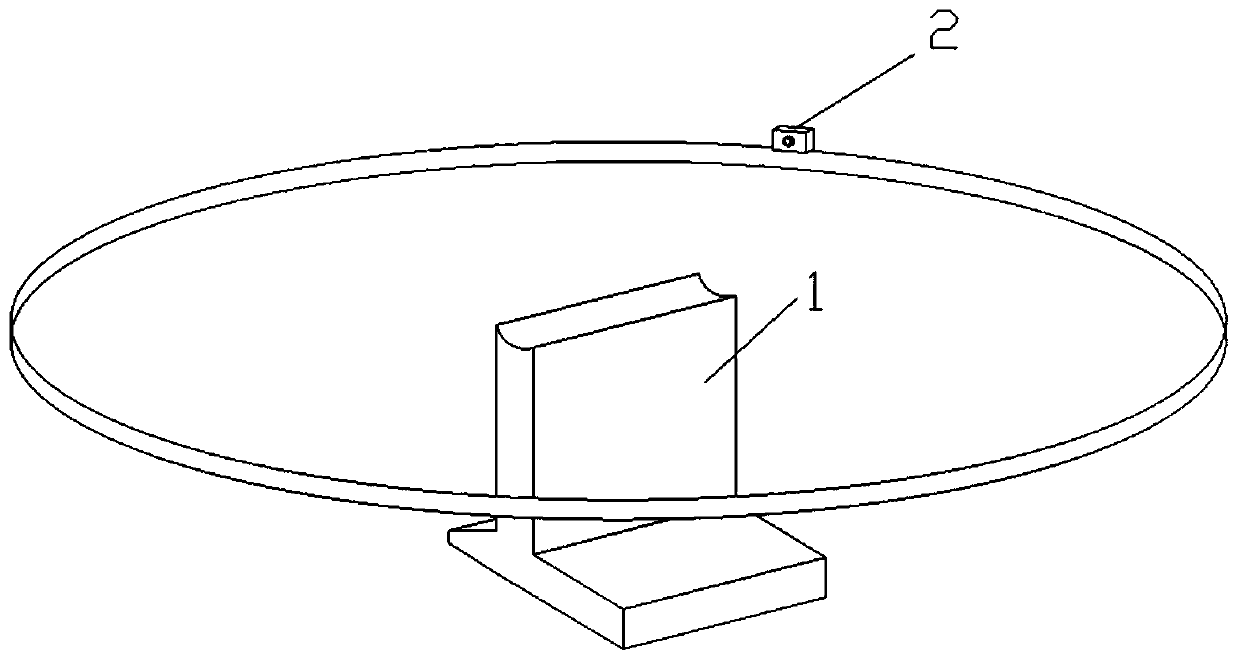

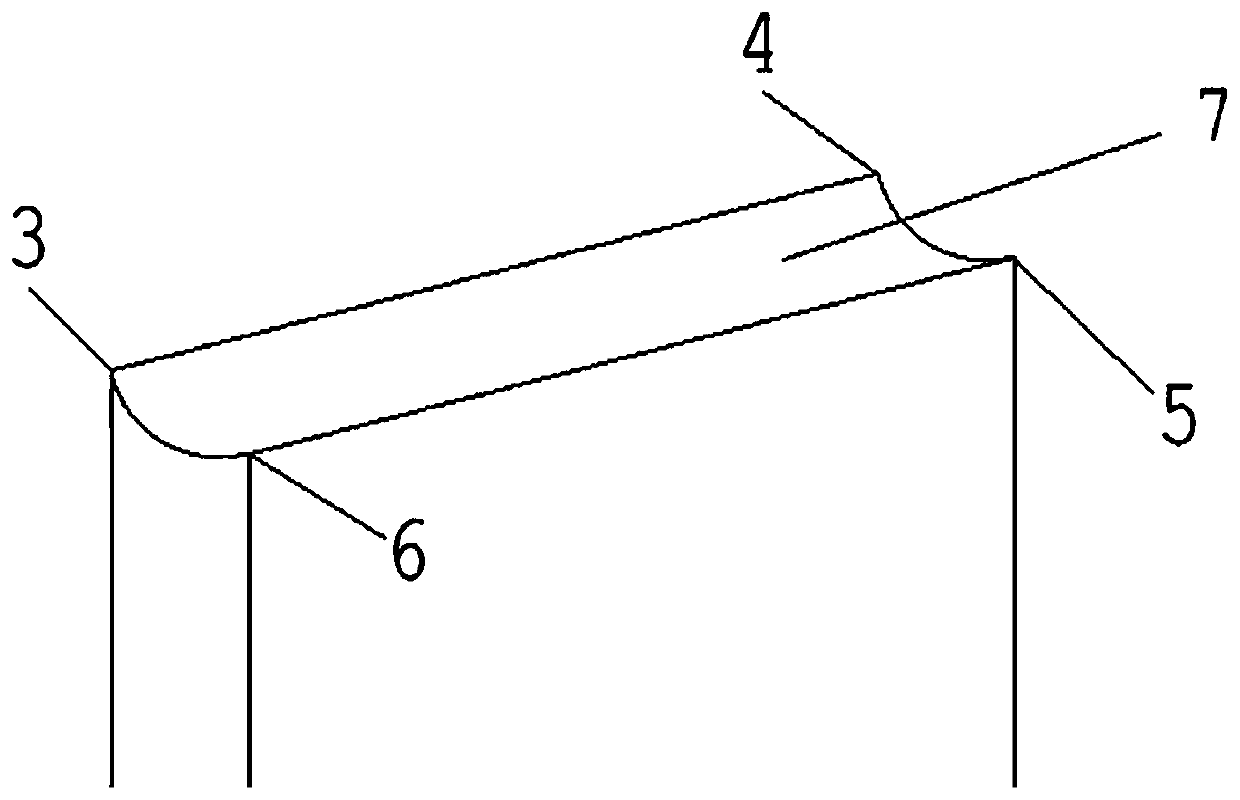

[0034] The present invention provides an automatic inspection method for the structural size of the arc-shaped hinge joint 7 of the assembled culvert segment. The method records the shape data of the assembled culvert segment 1 by taking photos, and then reconstructs and generates a point cloud of the structure of the arc-shaped hinge joint 7 model, select the local feature points and match the point cloud model of the curved joint 7 with the corresponding reference points on the design model, compare the error between the point cloud model and the design model, and realize the prefabricated culvert Automatic detection of structural dimensions of segment arc hinge joint 7.

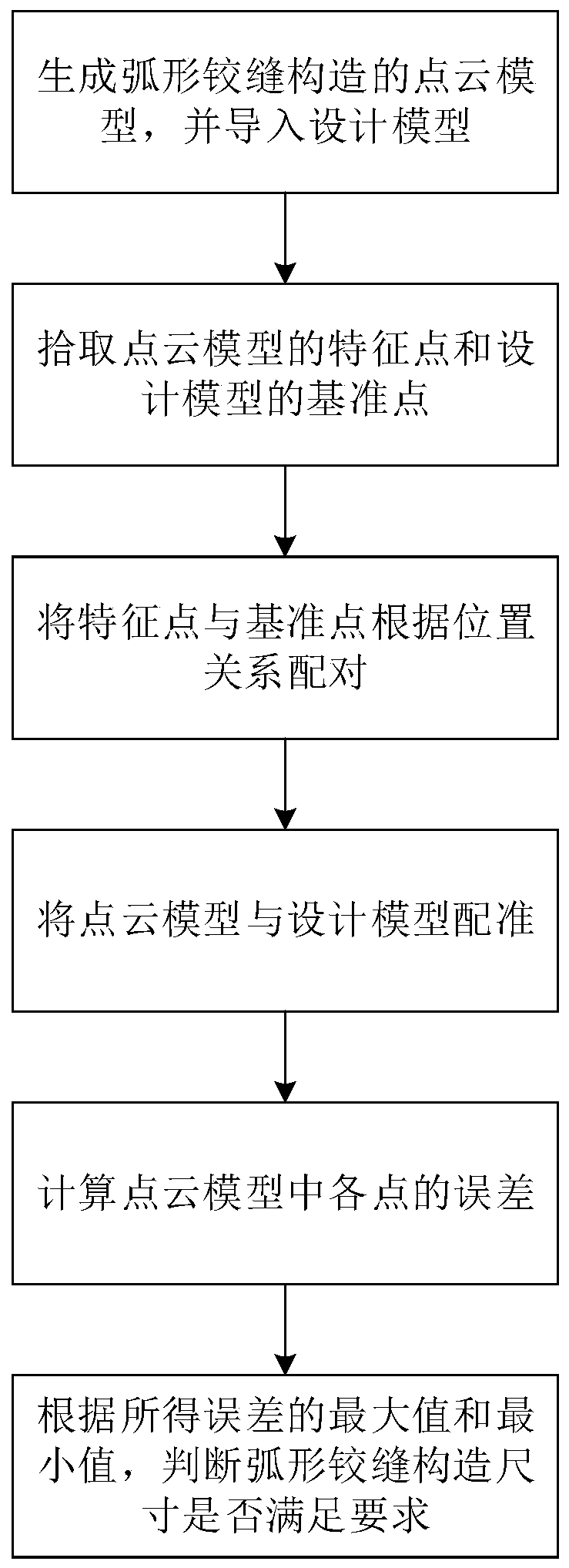

[0035] Such as figure 1 shown, including the following steps:

[0036] S1) Obtain the point cloud model constructed by the arc hinge joint 7, and import the design model;

[0037] S2) pick up the feature points of the point cloud model and the reference points of the design model;

[0038] S3) pairing t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com