Method for manufacturing positioning insert for reactor internal in AP1000 nuclear power station

A technology of internal components and nuclear power plants, applied in the field of nuclear power plant construction, can solve problems such as long time-consuming, heavy workload, and difficult measurement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] Below, combine Figure 1-6 The method for making positioning inserts for internal components in the AP1000 nuclear power plant of the present invention will be described in detail.

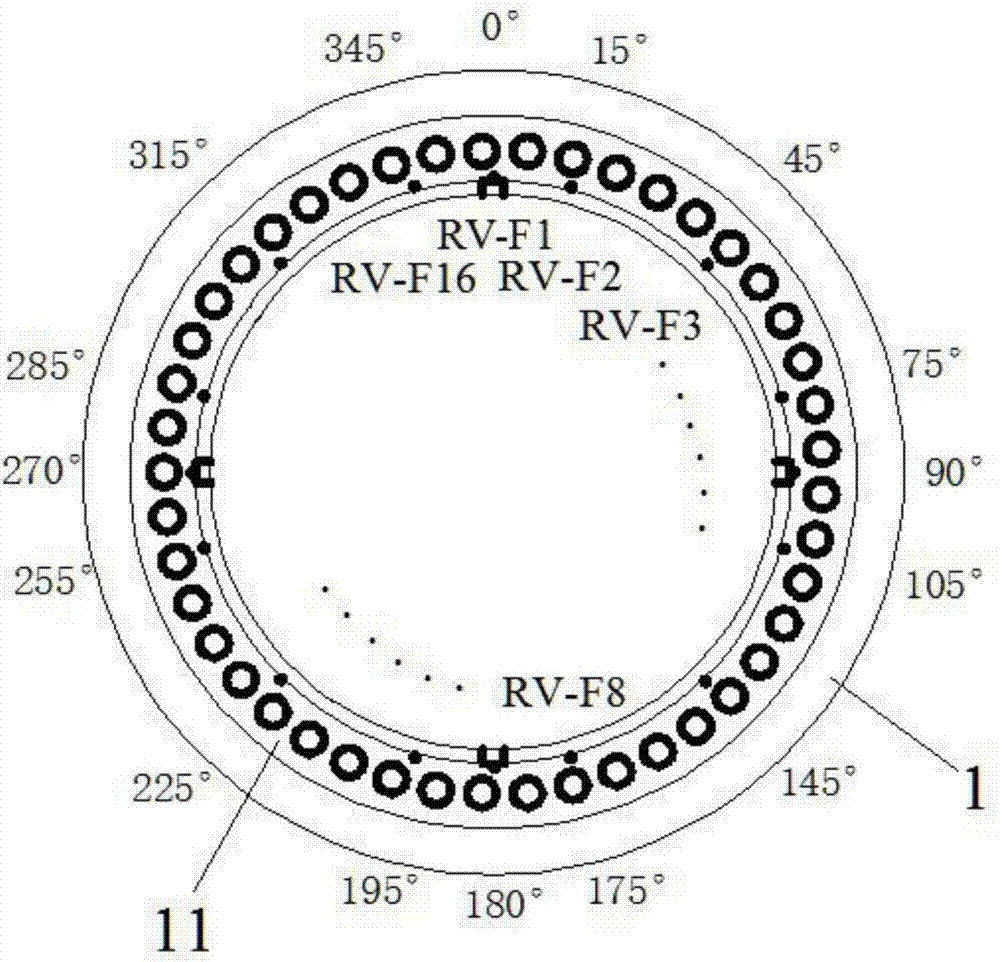

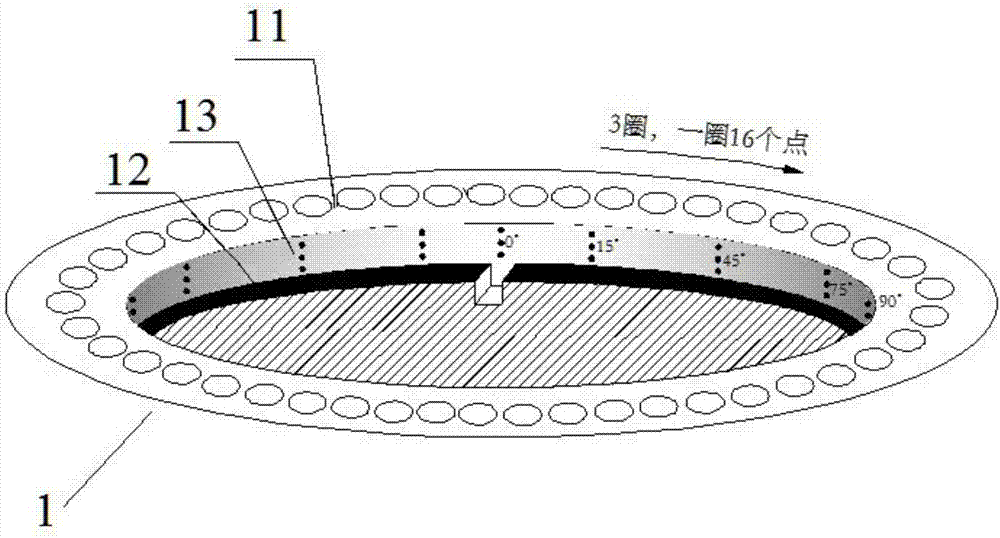

[0028] Arrange RV measurement points on the pressure vessel, and the RV measurement points include RV flange measurement points, core support surface measurement points, connected inner wall measurement points, radial support keyway measurement points, positioning pin groove measurement points and RV nozzles Measuring point. Wherein, the RV flange measuring point is located on the inner circle of the upper flange of the pressure vessel, and at least 8 RV flange measuring points are arranged on the inner circle of the upper flange. Such as figure 1 As shown, 16 RV flange measurement points are arranged on the inner circle of the upper flange 11 of the pressure vessel 1, and these RV flange measurement points are regarded as a group of measurement points, which are marked as RV-F1, RV-F2, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com