Assembly practical training production line for automatic gear pump

A gear pump and production line technology, which is applied in the direction of educational appliances, instruments, teaching models, etc., can solve the problems that there is no analog mechanical and electrical product production line, etc., and achieve the effect of convenient and efficient use, convenient use and high use efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

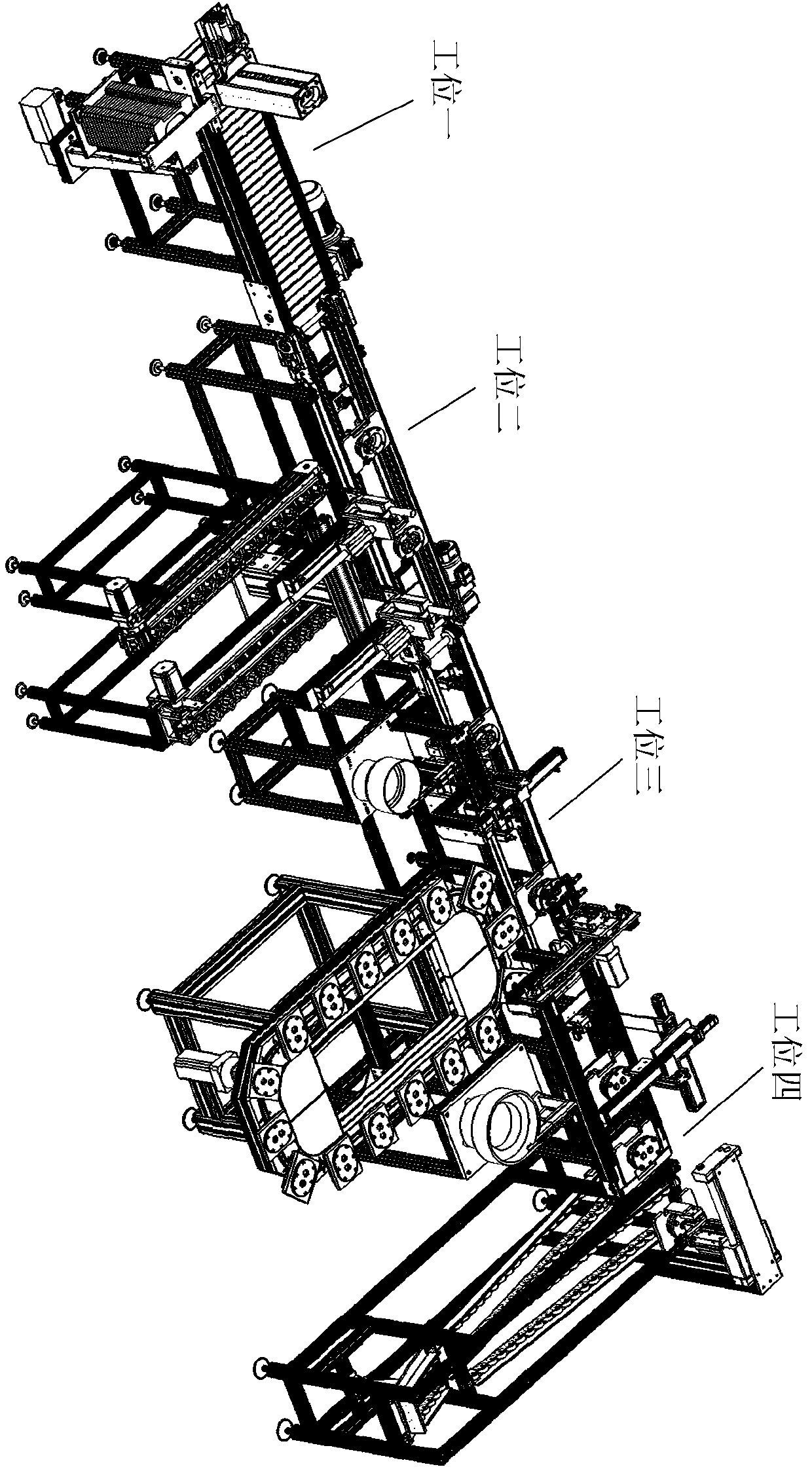

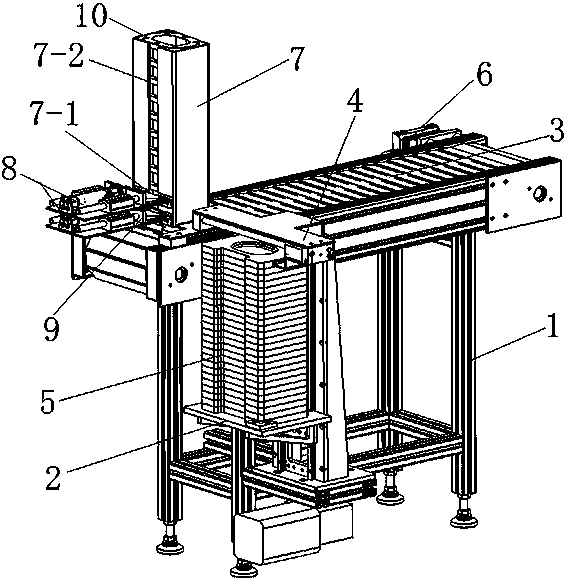

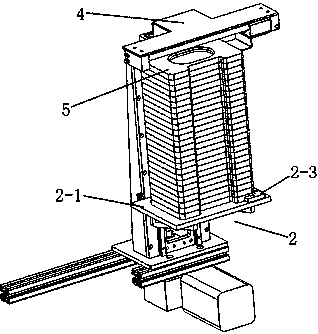

[0095] Refer to attached Figure 1-17 , an automatic gear pump assembly training production line includes: station one, station two, station three and station four; wherein station one is the pump body assembly station, station two is the gear assembly station, and station two is the gear assembly station. The third station is the cover plate assembly station, and the fourth station is the finished product assembly station; the automatic gear pump assembly training production line also includes the control device, which is connected with the first station, the second station, the third station and the fourth station respectively. Data Connections.

[0096] The control device is an industrial computer, a PLC programmable controller or a single-chip microcomputer.

[0097] Refer to attached figure 1 , an automatic gear pump assembly training production line of the present invention is assembled through station one, station two, station three and station four in sequence; in st...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com