Outdoor totally-enclosed composite insulation three-phase combined mutual inductor

A combined transformer and composite insulation technology, applied in the field of transformers, can solve problems such as increased labor and equipment costs, difficulty in professional recycling, and low volatility, so as to reduce the workload of inspection and maintenance, and facilitate daily maintenance. The effect of structural fit

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

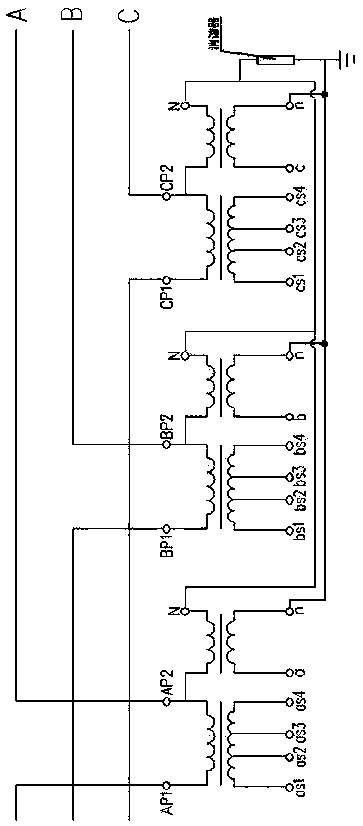

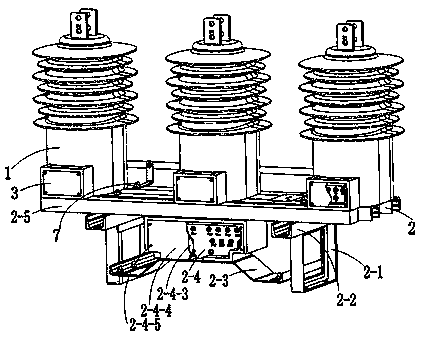

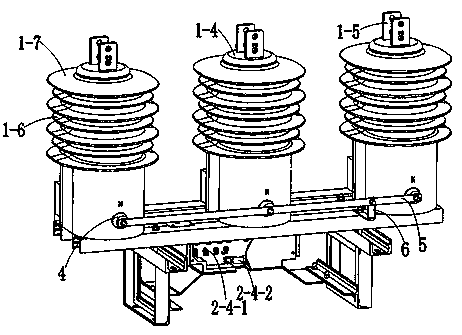

[0035] Below in conjunction with accompanying drawing, the specific embodiment of the present invention is described in detail as follows:

[0036] see Figure 1-5 , an outdoor fully enclosed composite insulated three-phase combined transformer, including three single-phase combined transformers 1 with the same structure and a base 2, two frame-type support frames 2-1 are installed on the lower part of the base 2, each supporting Mounting holes are provided on the frame at the bottom of the frame 2-1, a fixing frame 2-2 is installed between the supporting frame 2-1 and the base 2, and mounting holes are provided at both ends of the fixing frame 2-2. A bridge support frame 2-3 is installed through bolts between the two support frames 2-1, a terminal box 2-4 is arranged on the bridge support frame 2-3, and a wire inlet hole is reserved on the top of the terminal box 2-4 , one side of the fixed frame 2-2 is provided with a cable tube 2-5, and the upper and lower ends of the cabl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com